Diesel Engine Fuel Horizontal Centrifugal Non-Clog Slurry Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Power plant Usage Diesel Engine Fuel Horizontal Centrifugal Non-Clog Slurry Pump

Product Description

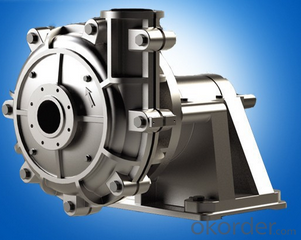

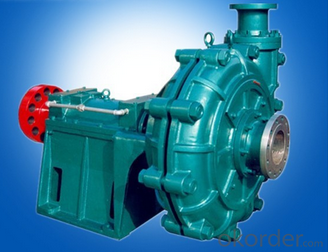

ZJ series centrifugal slurry pump suitable for handling abrasive and corrosive mine slurry with

maximum concentrations of wt.45%(ash) and wt.60%(ore).They are widely used in power ,

metallurgy, ming ,coal and construction materials.The ZJ series centrifugal slurry pump can be

operated in series according to requirements of users .

Performance table of centrifugal slurry pump of ZJ type

| Type | Q | H | n | η | |

| Flux | head | Speed | Efficiency | (NPSH)r | |

| (m³/h) | (m) | (r/min) | (%) | (m) | |

| 40ZJ-I-A19 | 8-50 | 9-57.1 | 1400-2900 | 50 | 1.3-4.5 |

| 80ZJ-I-A52 | 40-242 | 15-109 | 980-1480 | 66 | 2.3-4 |

| 100ZJ-I-A50 | 64-360 | 24-100 | 980-1480 | 68 | 2.3-5.1 |

| 200ZJ-I-A85 | 300-900 | 36-130 | 730-980 | 75 | 2.5-4.3 |

| 300ZJ-I-A95 | 700-1800 | 30-70 | 490-980 | 78 | 1.7-7.0 |

| 350ZJ-I-F100 | 860-1300 | 37-62 | 490-590 | 60 | 4.4-5.8 |

Note :The form is for clean water performance .Particular case ,contact the supplier.

AH centrifugal slurry pump are horizontal centrifugal pump that are suit for metallurgy ,mine,coal,

electric power and bulding materials to transport slurry with stong corrosion and high concentration.

The centrifugal slurry pump can be also used by multistage in series.The slurry body has changeable metal

lined , rubber lined or ceramic lined .The impeller is made of antifrictionmetal or rubber.

Shaft glands of AH slurry pump can adopt packing seal or centrifugal seal.Positong of opening

in the pump can be spaced 45° angle,turn eight different angles for installation

Performance table of centrifugal slurry pump of AH type

| Type | Flux | Head | Speed | Max. Power |

| 1.5/1 AH | 12.6-28 | 6-68 | 1200-3800 | 15 |

| 3/2 AH | 36-136.8 | 12-87 | 850-2700 | 60 |

| 4/3 AH | 79.2-252 | 5-97 | 600-2200 | 120 |

| 6/4 AH | 162-1008 | 40-280 | 500-1600 | 560 |

| 8/6 AH | 360-1228 | 7-95 | 400-1140 | 1200 |

| 10/8 AH | 640-1368 | 10-66 | 400-1100 | 560 |

| 12/10 AH | 720-1980 | 7-68 | 300-800 | 560 |

| 14/12 AH | 1152-2772 | 13-63 | 300-500 | 560 |

| 16/14 AH | 1368-3798 | 11-75 | 250-550 | 1200 |

| 18/16 AH | 1260-5040 | 8-66 | 200-400 | 1200 |

| 20/18 AH | 2520-5400 | 13-57 | 200-500 | 1200 |

- Q: 2 different pulleys are in the way of the 2 remaining long bolts. at each end of the pump. tensioner did not need to be moved as belt is already off. Motor mount is 1/2 way removed and motor has dropped slightly gt; Am reading a jack must be placed under motor with wood via oil pan ( am hoping no other damage was done) Am told there is a certain device available to remove the pulleys? ... -Would appreciate anyone's info and advice on the remaining steps to this procedure on this make and model engine. as I have come into it obviously with it having begun the wrong way!! Thanks!!

- Are you sure? Try using a search engine (could be Bing, Yahoo, Google).

- Q: I am trying to increase the pressure of my shower and I am looking to install a water pump. Does anyone know what kind of pump would work well for this? I don't want a big pressure pump, just a small one that will be cheap.

- American Standard has a shower head with a turbine in it. Get that. its made for low flow applications.

- Q: When did the pump start?

- The promotion of water is very important to human life and production. There are various ancient water appliances, such as Egypt's chain pump (seventeenth Century BC), China shadoof (seventeenth Century BC), Burton (Eleventh Century BC) and water (first Century ad). The famous spiral rods invented by Archimedes in the third Century BC can lift water to a few meters in a steady and continuous way, and the principle is still used by modern screw pumps.In 200 BC, the ancient Greek fire pump craftsmen invented by Kurt Siby Lucius is a kind of piston pump has the most original, the main components of a typical piston pump piston pump, but only after the steam engine was developed rapidly.1840~1850 years, the United States invented Worthington pump cylinder and steam cylinder opposite, the direct impact of the piston pump, marking the formation of modern piston pumps. Nineteenth Century was the climax of the development of piston pumps, which were already used in a variety of machines, such as water presses. However, with the rapid increase in water demand, from 1920s, the piston pumps with low speed and large flow were gradually replaced by high-speed centrifugal pumps and rotary pumps. But in the field of high pressure and small flow, reciprocating pump still occupies the main position, especially diaphragm pump and plunger pump have their own advantages and are used more and more.

- Q: My toilet has a water pump to deposit water to the toilet and a floatie that will stop the flow. But now it does not flow water through the hose, instead it looks like it's clogged and water drips from the floatie handle. Do i need to replace it? Or could it be something easy to fix?

- The okorder /... Every hardware store has them. You can get the part I think it is 400A that doesn't have the flapper included. I'm not crazy about fluidmaster flappers because they always leak on me after a very short while.

- Q: ive been doing repair work on an old 86 jeep cherokee and when i let it idle there is a water leak, me and my dad came to the conclusion there was something wrong with the water pump. i cant find the manual and i dont even know what im looking for, so where would i find the water pump and how would i go about replacing it?

- hello ok... you have some issues to ascertain... a million, be certain you placed the theromstat interior the final way. 2, examine each and all of the hoses... you have got one thats kinked or collapsed. ( normally the single close to the backside of the radiator. 3, replace the radiator cap. the actual one on the radiator. it must be venting each and all of the time subsequently no longer permitting the water rigidity to upward push while the engine is working. confident the gadget is presureised via the rigidity of the water pump..... 4, you have got a sludge blockage interior the radiator its self. Take the hose off the backside, permit each and all of the fluid run out. placed hose in perfect of radiator and only flush.... 5, the reason the heater isnt working is becasue the water isnt circulating... subsequently me thinking theres a blockage incredibly once you stated no water comes out of the bleed screw. What shade is the coolant in theradiator... is it clean, is it the fairway or blue shade of coolant further. Or is it a rusty shade. additionally ... look on the oil cap.. look interior it.. is there a whitish foam. additionally examine your dipstick. Is the oil clean , or is it milky looking. If its milky then you definately've got a blown cylinder head gasket . The coolant would be going into the cylinders. and not cooling the engine. I desire you success with this and that i'm hoping its somything so undemanding as a blocked radiator.

- Q: need to know the electrical connections for a Square D water pump pressure switch..Have a quot;blacka quot;Redand the quot;ground quot;of course

- The two source wires connect to L1 and L2. The two pump wires connect to T1 and T1. The grounds get grounded. When the pressure falls, the contacts pull together and connect L1 to T1, and L2 to T2, and start the pump.

- Q: Water pump. A drip on the edge of the pump or drip on the ground. Serious concern on which one?

- Anytime you see coolant leaking from a water pump it is time to replace it. The sooner the better.

- Q: or how do i remove the water pump?please xplain

- You need to get the large nut lose. It holds the fan/fan clutch to the water pump shaft. After you get that off it's all down hill from there.A large adjustable wrench will work on the nut but you will need to keep pump from turning to loosen it. I think it may be left hand thread. It is not on real tight. The book will help on this one.

- Q: water pump on a Suzuki forenzakia optima

- You better shop around on that one but you're looking at a few hundred dollars minimum. The newer the car, the more you're going to pay to get it fixed.

- Q: Submersible pump and self-priming pump which is easy to use?

- Dive into the water and leave alone

Send your message to us

Diesel Engine Fuel Horizontal Centrifugal Non-Clog Slurry Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords