Dental Floss domestic convenient Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss domestic convenient Flossing

Brand: OEM/Ok Floss

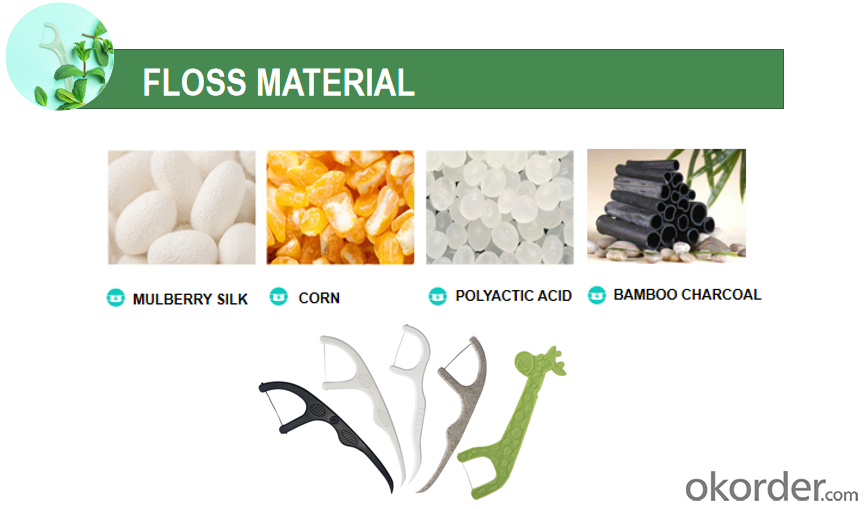

Floss material: UHMWPE OEM

Floss length: 7.4*2.2cm/25-30M/OEM

Wax: Import germany wax/american wax/bee wax/candelilla wax/customized wax

Flavor: Mint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss: original color

Floss original color: Individual bulk PP bag/individual paper box/as customized

Applications: Family,Hotel,Travel,Supermarket,Restaurant

Delivery: By sea,By air,By express.

Lead time: 20-30days

Description:

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots

where your toothbrush can’t reach, generally between your teeth and under the gumline.

A variety of flavors can be ordered.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why Flossing Is So Important

People who floss regularly have healthier gums. They have less gum bleeding, gum disease, bone loss, and inflammation.

Adding dental floss into your daily oral hygiene routine removes plaque and eliminates bacteria. This protects you from gingivitis, tooth decay, and bad breath.

The main thing to remember is that you should brush your teeth, floss, and use mouthwash every day! Any type of floss or water flosser will improve your oral health by picking up bacteria that your toothbrush left behind.

OK flosses will fit your personal preference and needs better than others.

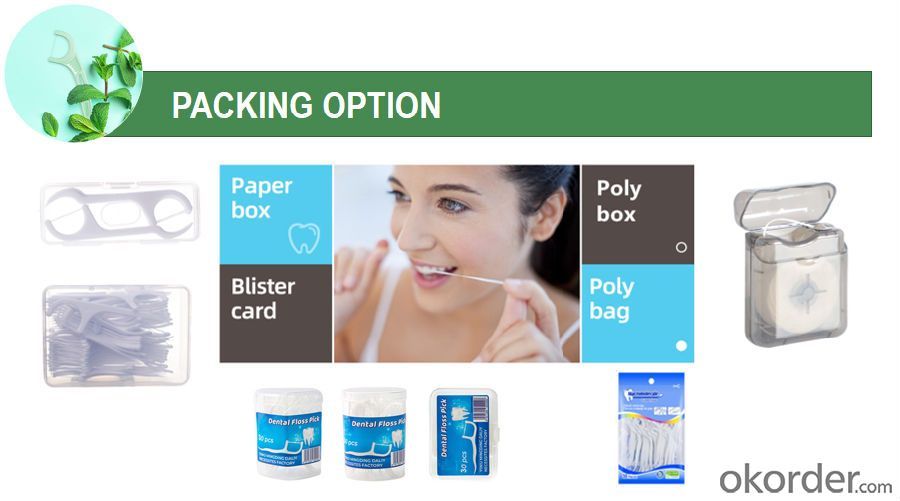

A variety of packaging can be ordered.

And multiple modes of transport.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand

and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How do medical plastics contribute to the development of telemedicine implants?

- Medical plastics play a crucial role in the development of telemedicine implants by providing biocompatible and lightweight materials that are essential for the functionality and safety of these devices. These plastics are used to create components such as casings, electrodes, and connectors, which are necessary for the proper functioning of telemedicine implants. Additionally, medical plastics offer excellent durability, flexibility, and resistance to chemicals and moisture, ensuring the longevity and reliability of these implants. Overall, the use of medical plastics in telemedicine implants enables the advancement of remote patient monitoring and healthcare delivery, enhancing the quality of care for patients.

- Q: What are the most common challenges in designing medical plastic products?

- Some of the most common challenges in designing medical plastic products include ensuring biocompatibility, meeting regulatory requirements, balancing material properties, ensuring sterilizability, and maintaining cost-effectiveness.

- Q: Can medical plastic be used in bioresorbable implants?

- Yes, medical plastic can be used in bioresorbable implants. Bioresorbable implants are designed to gradually degrade and be absorbed by the body over time. Medical plastics, such as polylactic acid (PLA) and polyglycolic acid (PGA), are often used in the manufacturing of bioresorbable implants due to their biocompatibility and ability to safely degrade within the body. These materials can provide the necessary mechanical strength and support during the healing process before gradually breaking down and being absorbed by the body.

- Q: How do medical plastics contribute to the development of drug-eluting devices?

- Medical plastics play a crucial role in the development of drug-eluting devices by providing a suitable platform for the controlled release of drugs. These plastics are biocompatible, meaning they do not harm the body, and can be easily molded into various shapes and sizes. They are also capable of encapsulating drugs, protecting them from degradation and ensuring their release at a controlled rate. This enables drug-eluting devices, such as stents or implants, to deliver therapeutic substances directly to the targeted site, enhancing treatment effectiveness, reducing side effects, and improving patient outcomes.

- Q: How is medical plastic used in radiology applications?

- Medical plastic is used in radiology applications for a variety of purposes. It is commonly used to manufacture protective shields and covers for radiation equipment, such as X-ray machines and CT scanners, to ensure the safety of both patients and medical professionals. Additionally, medical plastic is used to produce imaging contrast agents, which help enhance the visibility of certain body structures during radiographic examinations. It is also employed in the production of flexible tubing and catheters used in interventional radiology procedures. Overall, medical plastic plays a vital role in ensuring the effectiveness, safety, and efficiency of radiology applications.

- Q: Can plastic products be scrubbed with medical alcohol?

- Can plastic products be scrubbed with medical alcohol?

- Q: What are the limitations of medical plastic in certain applications?

- One limitation of medical plastic in certain applications is its potential to leach harmful chemicals or toxins into the body. Additionally, medical plastics may not be suitable for certain sterilization methods or may degrade over time, compromising their integrity. Another limitation is their inability to provide the same level of strength and durability as other materials, limiting their use in certain medical devices or implants.

- Q: How is medical plastic recycled or disposed of?

- Medical plastic is typically recycled through specialized recycling programs that are equipped to handle the unique challenges associated with medical waste. These programs ensure that the plastic is properly sorted, cleaned, and processed to be transformed into new products. In cases where recycling is not possible, medical plastic may be disposed of through regulated methods, such as incineration or landfilling, to minimize environmental impact and ensure compliance with waste management regulations.

- Q: Can medical plastics be used in gastrointestinal devices?

- Yes, medical plastics can be used in gastrointestinal devices.

- Q: Are medical plastics resistant to wear and tear?

- Yes, medical plastics are designed to be resistant to wear and tear. They undergo rigorous testing and are specially formulated to withstand the demands and stresses of healthcare environments, ensuring durability and longevity.

Send your message to us

Dental Floss domestic convenient Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches