Biodegradable sanitary floss with toothpick natural floss rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

100% Biodegradable Dental Floss Pick Eco-Friendly Flosser With Tooth Pick Natural Dental Floss Pick

| Brand | OEM/Ok Floss |

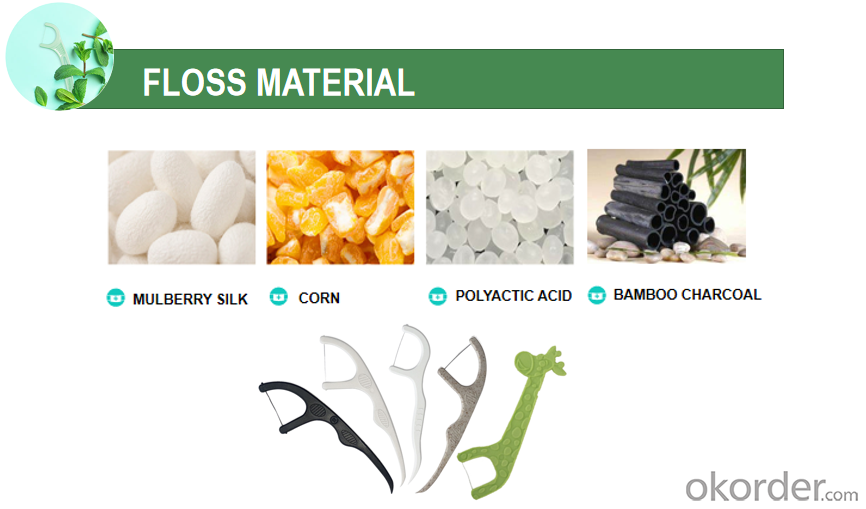

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

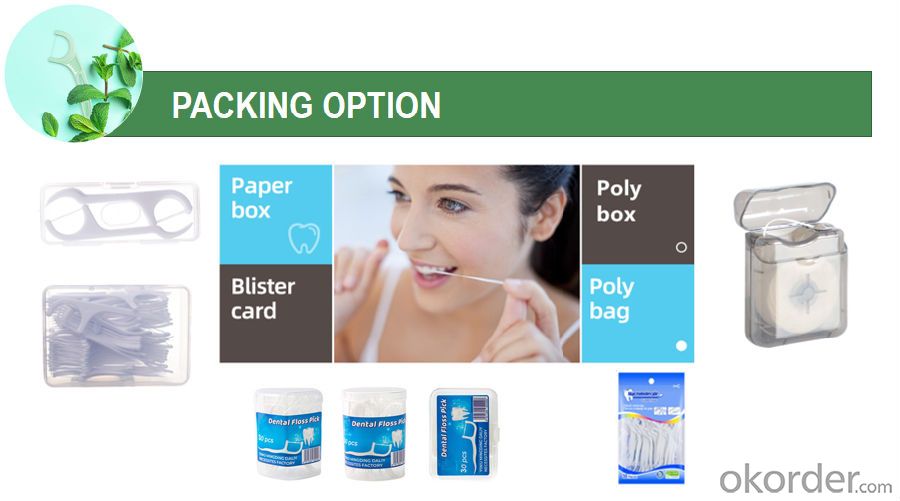

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How is medical plastic used in sports medicine?

- Medical plastic is widely used in sports medicine for various purposes. It is used to manufacture durable and lightweight orthopedic braces, splints, and casts that provide support and immobilization to injured athletes. Additionally, medical plastic is utilized in the production of prosthetics and joint replacements, allowing athletes to regain mobility and continue participating in sports. The material's biocompatibility and versatility make it ideal for creating medical devices and equipment used in the treatment and prevention of sports-related injuries.

- Q: Are medical plastics durable?

- Yes, medical plastics are generally durable. They are designed to withstand various sterilization techniques, everyday use, and provide long-term performance in medical settings.

- Q: Smash PVC plastic and wear any mask

- Imported Pu Yan conforms to the highest standard of American medical masks, and has good filtration, not only anti particles, but also anti droplets. The particles as small as 0.1 micron filtration efficiency up to 99.8% of bacteria or virus vector as small as 0.3 microns (common in droplet) filtration efficiency is up to 99.9%.

- Q: How does medical plastic help in preventing allergic reactions?

- Medical plastics are often hypoallergenic, meaning they have a low likelihood of causing an allergic reaction. These materials are carefully selected to minimize the presence of allergens and irritants, such as latex or certain chemical additives, which can trigger allergies in some individuals. By using medical plastic products, healthcare providers can reduce the risk of allergic reactions in patients, making it a safer option for medical procedures and treatments.

- Q: How do medical plastics help in wound healing?

- Medical plastics help in wound healing by providing a sterile and protective barrier over the wound. They prevent contamination from external factors, such as dirt and bacteria, allowing the wound to heal without further complications. Additionally, some medical plastics have properties that promote moisture retention, which helps create an optimal environment for wound healing. These materials are also flexible and conformable, ensuring comfort and ease of movement for the patient while facilitating the healing process.

- Q: Can medical plastics be used in oncological applications?

- Yes, medical plastics can be used in oncological applications. They are widely used in cancer treatment and research for various purposes such as drug delivery systems, surgical implants, radiation shielding, and diagnostic tools. The unique properties of medical plastics, such as biocompatibility, flexibility, and ease of manufacturing, make them suitable for a range of oncological applications.

- Q: How does medical plastic impact the environment?

- Medical plastic can have a significant impact on the environment due to its production, usage, and disposal. The manufacturing process of medical plastic requires the extraction of fossil fuels and generates greenhouse gas emissions. Additionally, the disposal of medical plastic waste often leads to pollution, as it can end up in landfills or incinerators, releasing harmful chemicals and contributing to microplastic pollution. Furthermore, the long lifespan of medical plastic contributes to its persistence in the environment, exacerbating its environmental impact.

- Q: How is medical plastic used in laboratory equipment?

- Medical plastic is used in laboratory equipment because it offers a range of beneficial properties. It is lightweight, durable, and resistant to chemicals, making it suitable for the manufacturing of various laboratory tools such as test tubes, petri dishes, pipettes, and sample containers. Medical plastic is also transparent, allowing researchers to easily observe and analyze samples. Additionally, it is often autoclavable, meaning it can be sterilized at high temperatures without losing its shape or integrity, ensuring the safety and reliability of laboratory experiments.

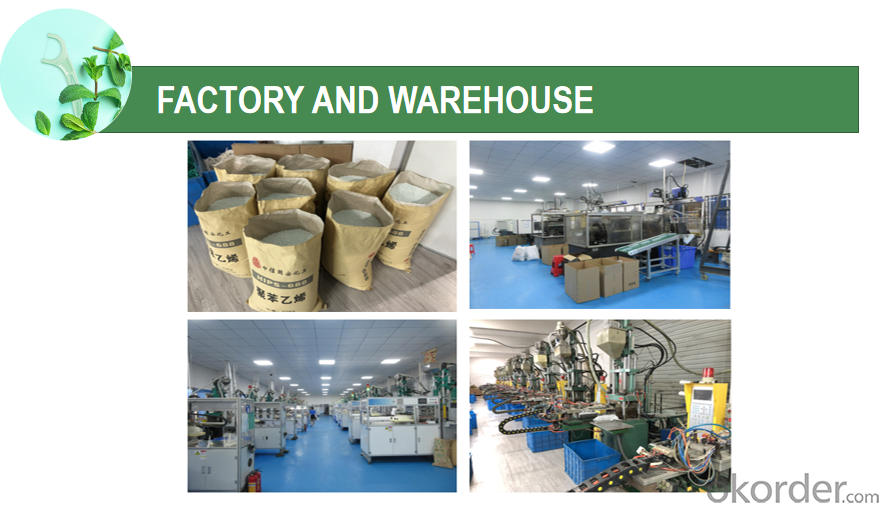

- Q: What are the considerations for preventing contamination during the manufacturing of medical plastic products?

- There are several considerations for preventing contamination during the manufacturing of medical plastic products. Firstly, maintaining a clean and controlled manufacturing environment is crucial. This includes having dedicated cleanrooms or controlled areas, implementing strict hygiene protocols for staff, and regularly cleaning and disinfecting equipment and surfaces. Secondly, using high-quality raw materials that meet industry standards is essential. Manufacturers should ensure that the plastics used are free from contaminants and impurities that could pose a risk to patients or compromise the integrity of the product. Thirdly, implementing effective quality control measures throughout the manufacturing process is vital. Regular inspections, testing, and validation procedures should be in place to ensure that the products meet the required specifications and are free from any potential contamination. Additionally, proper handling and storage of the finished products are critical. Adequate packaging, labeling, and storage conditions should be maintained to prevent any contamination from occurring after the manufacturing process. Lastly, having a robust and efficient traceability system is important. This enables manufacturers to track and identify any potential sources of contamination, making it easier to address and prevent future issues. By considering these factors and implementing appropriate measures, manufacturers can significantly reduce the risk of contamination during the manufacturing of medical plastic products, ensuring the safety and effectiveness of the final products for patients.

- Q: Can medical plastics be used in dental implants?

- Yes, medical plastics can be used in dental implants. Polymers such as polyetheretherketone (PEEK) and poly(methyl methacrylate) (PMMA) are commonly used in dentistry for fabricating dental implants, dentures, and other dental prosthetics. These materials offer excellent biocompatibility, durability, and aesthetic properties, making them suitable for use in dental applications.

Send your message to us

Biodegradable sanitary floss with toothpick natural floss rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords