Dental Floss Various Flavors Hygienic Cleanliness Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Various Flavors Hygienic Cleanliness Flossing

| Brand | OEM/Ok Floss |

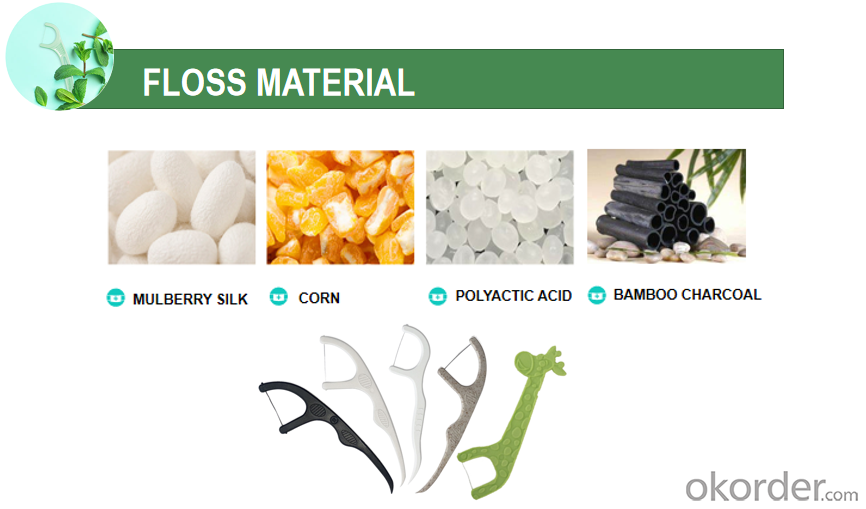

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

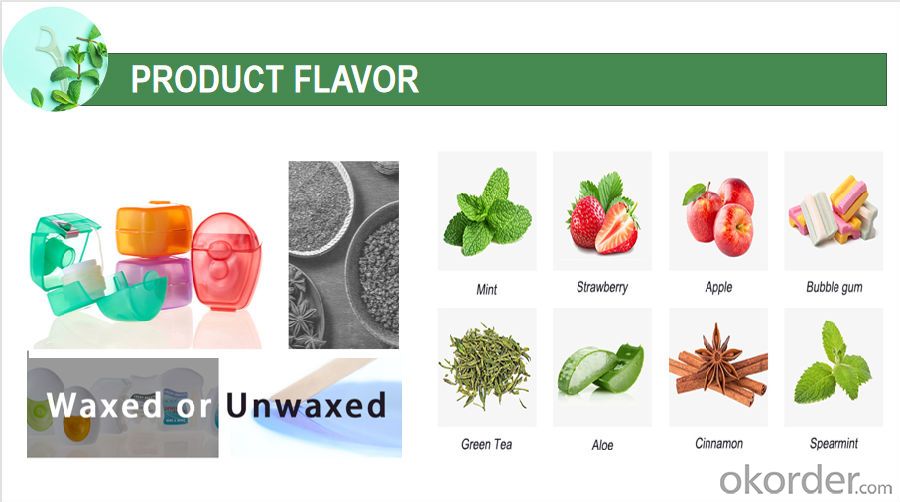

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Description

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

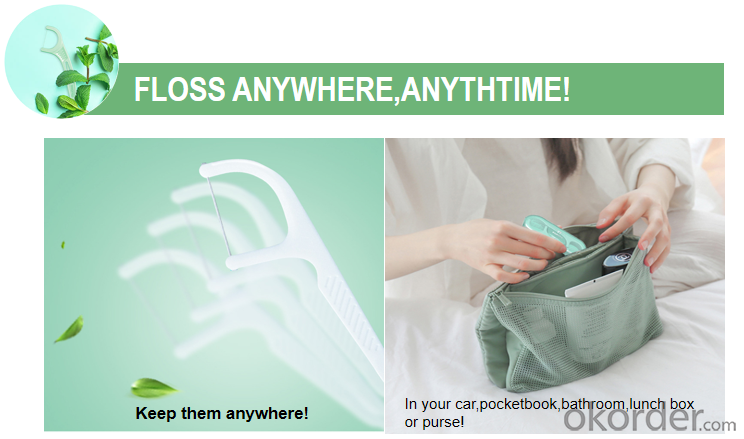

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

400D UHMWPE EXTRA STRONG FLOSS

Thin,strong,high resilience non-braching.Using supper smooth food

grade.UHMWPE floss ,not easy to stretch shred ,or break.

HIPS HANDLE

HIPS HANDLE

Food grade PS material,safe,solid,Antiskid.Comfortable to hold for precise cleanig.

TOOTHPICK TAIL

Pointed-end remove foof residue effectivelly.Using food grade material,special

curved design toothpick,better for deep cleanig.

Made with super protected pick that tuffloss that doesn’t stretch,shred or break.

Protested pick that floss away for use.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

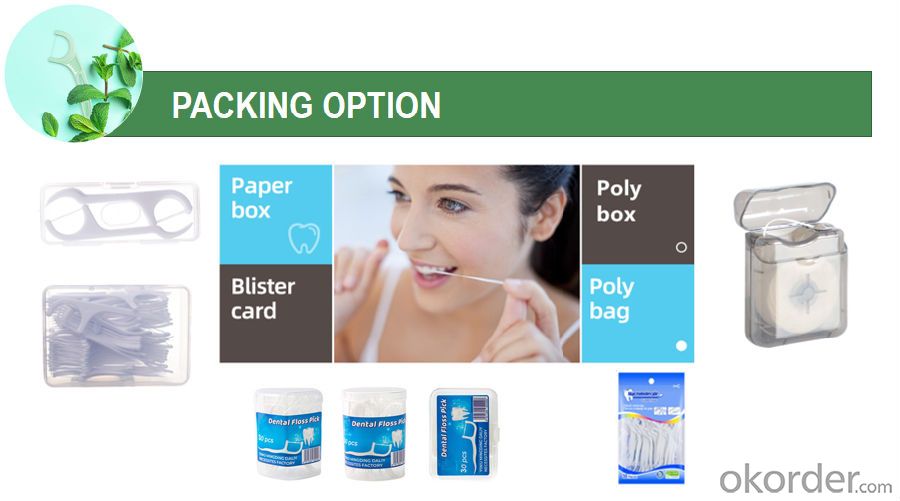

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What are the main challenges in developing medical plastics?

- One of the main challenges in developing medical plastics is ensuring their biocompatibility, as they need to be safe for use inside the human body. Additionally, medical plastics must possess the necessary mechanical properties to withstand different medical procedures and be able to integrate seamlessly with other medical devices. Another challenge is the need for sterilization, as medical plastics must undergo rigorous sterilization processes without compromising their physical or chemical integrity. Furthermore, the development of medical plastics requires strict adherence to regulatory standards and certifications, adding another layer of complexity to the process. Overall, balancing safety, functionality, compatibility, and regulatory compliance are the key challenges in developing medical plastics.

- Q: What is the density of foam plastics and what are the ingredients and uses of foams?

- The main raw material of polystyrene foam tableware with polystyrene, talcum powder, calcium stearate, butane etc..PS: its process is monomer styrene under high temperature, high pressure and catalyst action, in the sealed reactor polymerization. Although styrene is an aromatic compound, its reaction is carried out under sealed anaerobic conditions without producing dioxin conditions and is in line with food hygiene and requirements. Talc: it is an inorganic mineral (containing magnesium silicate hydrate), dosage of about 1%, played a nucleating role, medical grade.

- Q: How does medical plastic help in ophthalmic applications?

- Medical plastic is a crucial component in ophthalmic applications as it offers several benefits. It is lightweight, flexible, and transparent, enabling the production of various optical devices such as lenses, intraocular implants, and contact lenses. The use of medical plastic ensures high optical clarity, allowing for accurate vision correction and improved patient comfort. Additionally, medical plastic is biocompatible, meaning it is well-tolerated by the human body, reducing the risk of adverse reactions or complications. Overall, medical plastic plays a significant role in enhancing the effectiveness and safety of ophthalmic treatments and products.

- Q: Are there any risks associated with the use of medical plastics?

- Yes, there are some risks associated with the use of medical plastics. Some potential risks include leaching of harmful chemicals from the plastics into the medical devices or medications, which can lead to adverse effects on patients. Additionally, the disposal of medical plastics can contribute to environmental pollution and waste management issues. However, stringent regulations and quality control measures are in place to mitigate these risks and ensure the safe use of medical plastics.

- Q: What are the most common uses of medical plastics in respiratory care?

- Some common uses of medical plastics in respiratory care include the production of oxygen masks, nebulizer chambers, nasal cannulas, and endotracheal tubes. These plastic devices are essential in delivering oxygen and medications, facilitating breathing, and maintaining airway patency in patients with respiratory conditions.

- Q: What are the cost implications of using medical plastics in healthcare?

- The cost implications of using medical plastics in healthcare can vary depending on various factors. While medical plastics may initially have higher upfront costs compared to traditional materials, they often offer long-term cost savings. Medical plastics are lightweight, durable, and have excellent chemical resistance, reducing the need for frequent replacements. They also provide greater flexibility in design and manufacturing, potentially reducing production costs. Additionally, medical plastics can contribute to enhanced patient safety and infection control, potentially reducing healthcare-associated costs. However, careful consideration is necessary to balance the benefits and costs associated with medical plastics to ensure affordability and sustainability in healthcare.

- Q: Can medical plastics be used in contact lenses?

- Yes, medical plastics can be used in contact lenses.

- Q: What are the environmental implications of using medical plastics?

- The use of medical plastics has several environmental implications. Firstly, the production of these plastics often involves the extraction and processing of fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the disposal of medical plastics, such as syringes, IV bags, and tubing, can lead to environmental pollution if not properly managed. Improper disposal can result in plastics entering water bodies and soil, harming marine life and ecosystems. Furthermore, the slow degradation of medical plastics can persist in the environment for hundreds of years, further exacerbating the issue. Therefore, it is important to explore alternatives and improve plastic waste management in the healthcare sector to mitigate these environmental impacts.

- Q: Can medical plastic be safely used in gastrointestinal applications?

- Yes, medical plastic can be safely used in gastrointestinal applications. Medical-grade plastics such as polyurethane and silicone are commonly used in the production of various gastrointestinal devices and implants like feeding tubes, stomach tubes, and colostomy bags. These plastics are biocompatible, meaning they do not cause any adverse reactions or harm to the body when used in contact with the gastrointestinal tract. They are specifically designed to be safe for use in medical applications, ensuring patient safety and effective treatment of gastrointestinal conditions.

- Q: What are the benefits of using medical plastic in drug delivery?

- The benefits of using medical plastic in drug delivery include its versatility, cost-effectiveness, and ability to provide safe and secure packaging. Medical plastics can be molded into various shapes and sizes, allowing for customized drug delivery systems. They are lightweight, making them convenient for patients to handle and transport. Moreover, medical plastics are compatible with a wide range of drugs and can protect them from contamination, degradation, and tampering. Overall, the use of medical plastic in drug delivery helps ensure efficient and reliable administration of medications to patients.

Send your message to us

Dental Floss Various Flavors Hygienic Cleanliness Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches