Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

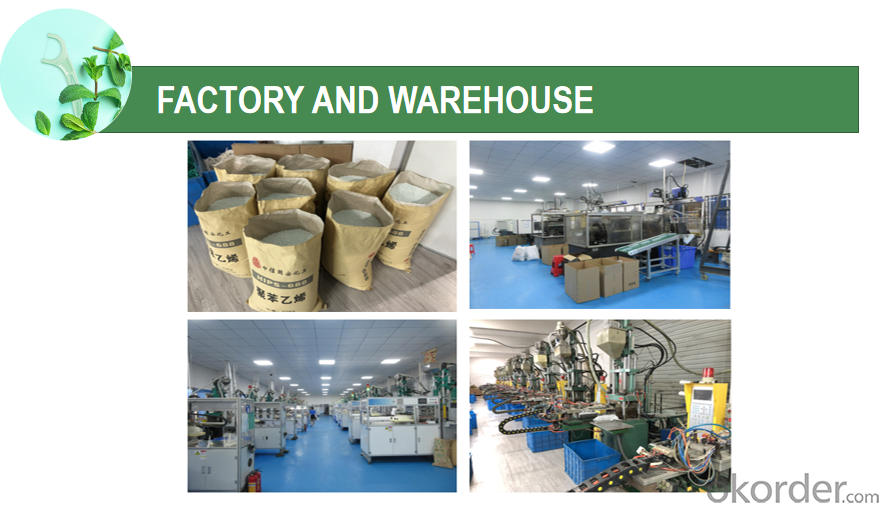

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

| Brand | OEM/Ok Floss |

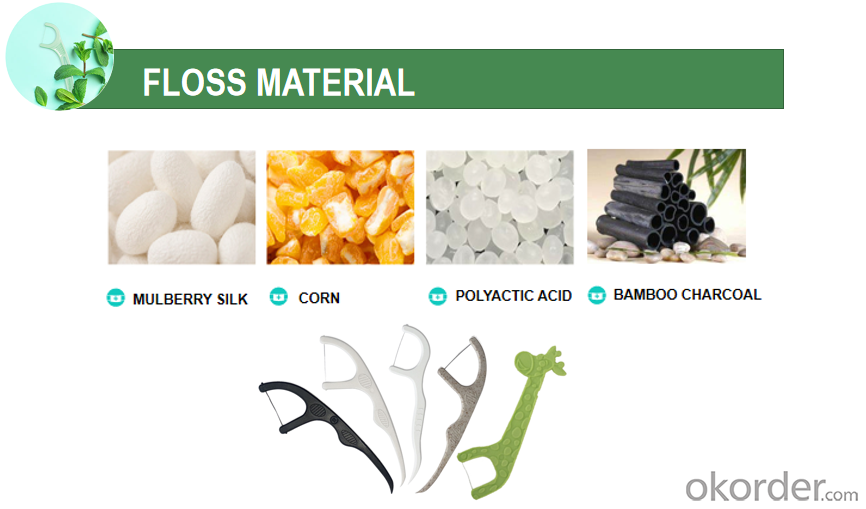

| Floss material | Charcoal /OEM |

| Floss length | 7.4*2.2cm、OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

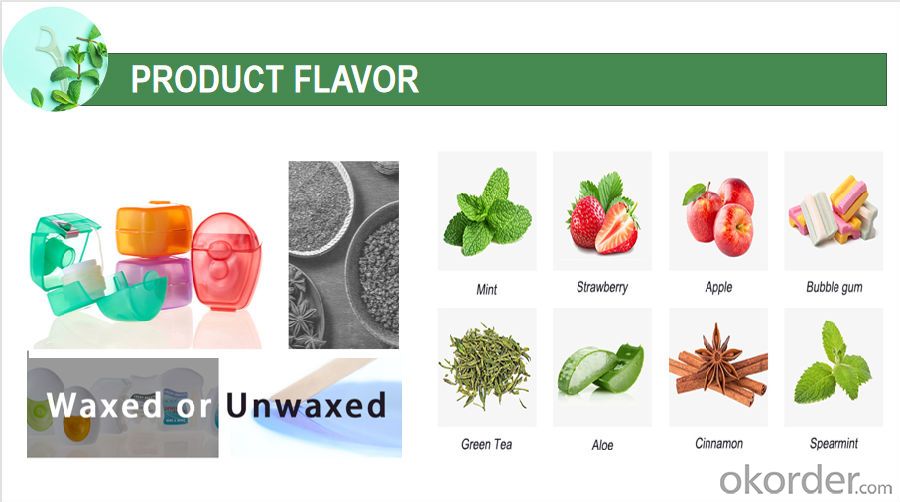

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Black |

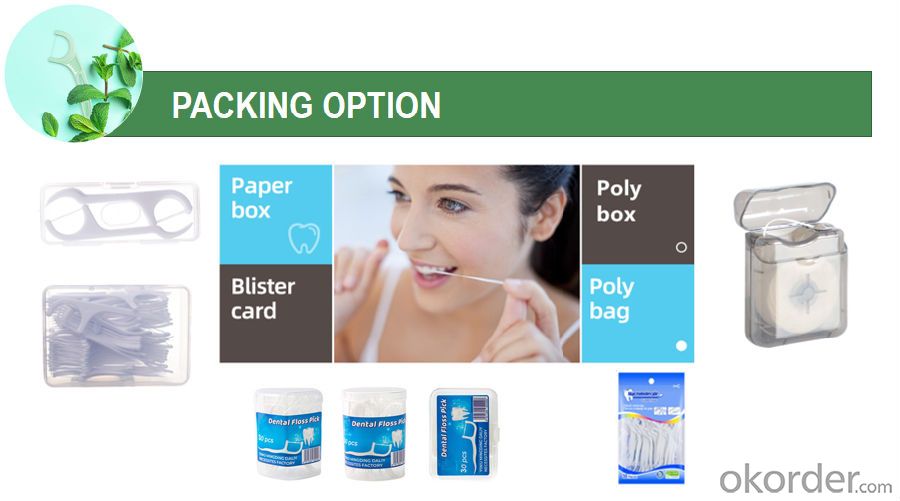

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Top quality dental floss for your business

Ok Floss help your oral care

Professional OEM/ODM provider

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: Glaucous, black plastic frame glasses frame how to get rid of?

- The main component of the detergent is surfactant, which is the organic compound in the two part of the molecular structure, which is hydrophilic and lipophilic.

- Q: How is medical plastic used in respiratory devices?

- Medical plastic is used in respiratory devices to create components such as masks, tubing, valves, and connectors. These devices rely on medical-grade plastic due to its biocompatibility, flexibility, and durability. The plastic materials used in respiratory devices are designed to be non-toxic and resistant to degradation, ensuring the safety and effectiveness of the devices.

- Q: Invisible shoulder strap, is it made of plastic material, or is it made of silicone?

- Of course, the silicone material is good, silicone is soft, more comfortable to wear. And the nature is more stable. You can't guarantee the quality of plastic. Who knows what kind of waste material is used?. The material will be harder.

- Q: What kind of plastic is used in medical instruments? Can also be sterilized at high temperature

- Ethylene oxide is difficult to transport, so you can see the supply locally. If you do not have the ability to disinfect, you can also find medical equipment company oem.

- Q: How does medical plastic contribute to the development of bioengineering tools?

- Medical plastic contributes to the development of bioengineering tools in several ways. Firstly, it provides a versatile and durable material that can be molded into various shapes and sizes, allowing for the creation of complex and intricate bioengineering devices. Additionally, medical plastics are often biocompatible, meaning they can be used safely in contact with biological tissues without causing adverse reactions. This property is crucial for the development of implantable devices and prosthetics. Moreover, medical plastics can be engineered with specific properties such as flexibility, transparency, and conductivity, enabling the design of innovative tools for diagnostics, drug delivery systems, and tissue engineering applications. Overall, medical plastic plays a vital role in advancing bioengineering by providing the necessary materials to create functional and safe tools that enhance medical treatments and improve patient outcomes.

- Q: How is medical plastic regulated and tested for compliance?

- Medical plastic is regulated and tested for compliance through rigorous processes and regulations. Regulatory bodies such as the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in Europe, and similar agencies worldwide establish guidelines and standards for medical plastic materials. These regulations outline the requirements for safety, quality, and performance of medical plastics. To ensure compliance, medical plastics undergo extensive testing. This includes biocompatibility testing to assess the material's interactions with living tissues, such as cytotoxicity, sensitization, and irritation tests. Other tests may include chemical analysis, mechanical testing, and sterilization validation. Manufacturers are responsible for conducting these tests and documenting their results to demonstrate compliance with regulatory requirements. Additionally, third-party testing laboratories may be involved in verifying the safety and efficacy of medical plastics. Overall, the regulation and testing of medical plastic are critical in ensuring the highest standards of safety and performance for medical devices and packaging materials used in healthcare settings.

- Q: How does medical plastic contribute to the development of telehealth technologies?

- Medical plastic plays a crucial role in the development of telehealth technologies by providing essential components such as lightweight and durable casings for telehealth devices, sterile packaging for medical equipment, and flexible tubing for fluid delivery systems. These materials are essential for creating portable, user-friendly, and hygienic telehealth devices, which are critical for remote patient monitoring, teleconsultations, and virtual healthcare services. Without the contribution of medical plastic, the advancement and widespread adoption of telehealth technologies would be limited.

- Q: Can medical plastic be safely used in orthopedic applications?

- Yes, medical plastic can be safely used in orthopedic applications. Medical-grade plastics are specifically designed to meet the stringent requirements of the healthcare industry, including orthopedics. These plastics are biocompatible, meaning they do not cause any adverse reactions or harm to the human body. They possess excellent mechanical properties, such as strength, flexibility, and durability, making them suitable for various orthopedic applications like implants, prosthetics, and surgical instruments. Additionally, medical plastics can be sterilized easily, ensuring a safe and hygienic environment for patients.

- Q: What are the most common uses of medical plastics in radiology?

- Medical plastics are commonly used in radiology for various purposes such as manufacturing imaging equipment, protective gear, medical devices, and packaging materials. Some specific examples include the production of X-ray machines, CT scanners, MRI equipment, radiation shields, syringes, contrast agents, and sterile packaging for medical supplies.

- Q: Can medical plastics be used in gastrointestinal devices?

- Yes, medical plastics can be used in gastrointestinal devices.

Send your message to us

Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords