Dental Floss Hot Sales Factor Price Wholesale Price High Quality ISO CE FDA Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Hot Sales Factor Price Wholesale Price High Quality ISO CE FDA Dental Floss Pick

| Brand | OEM/Ok Floss |

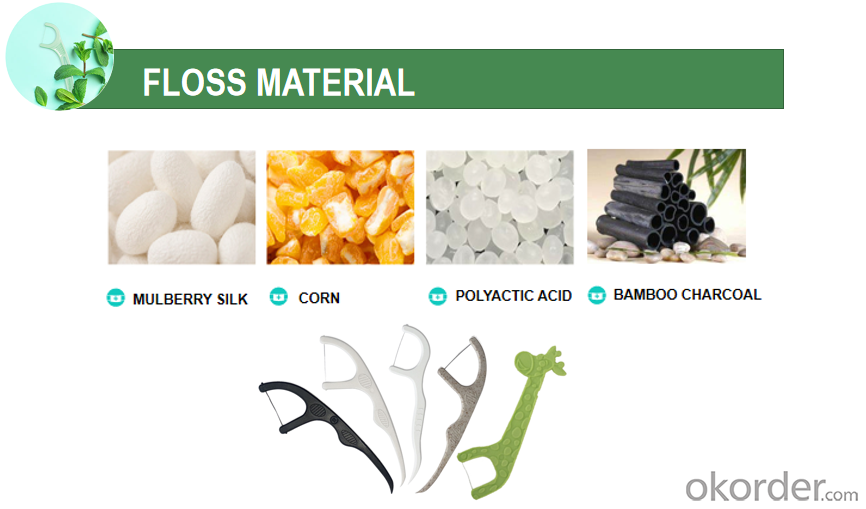

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

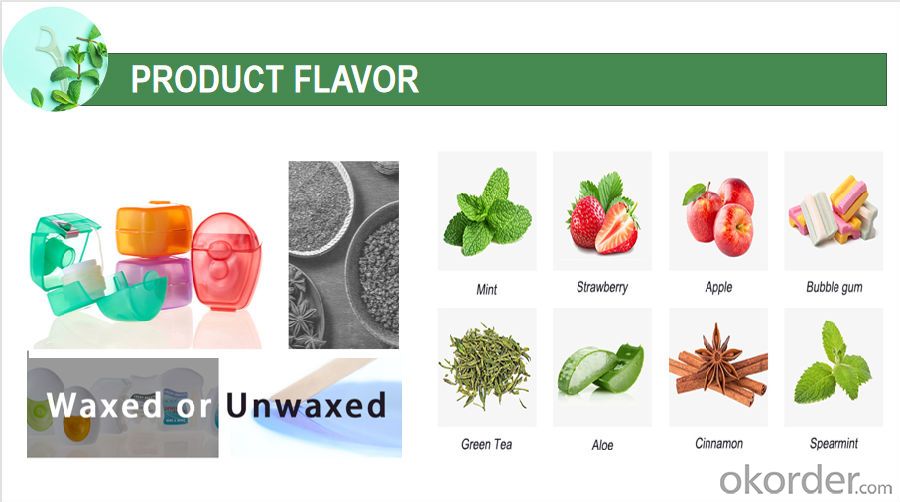

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

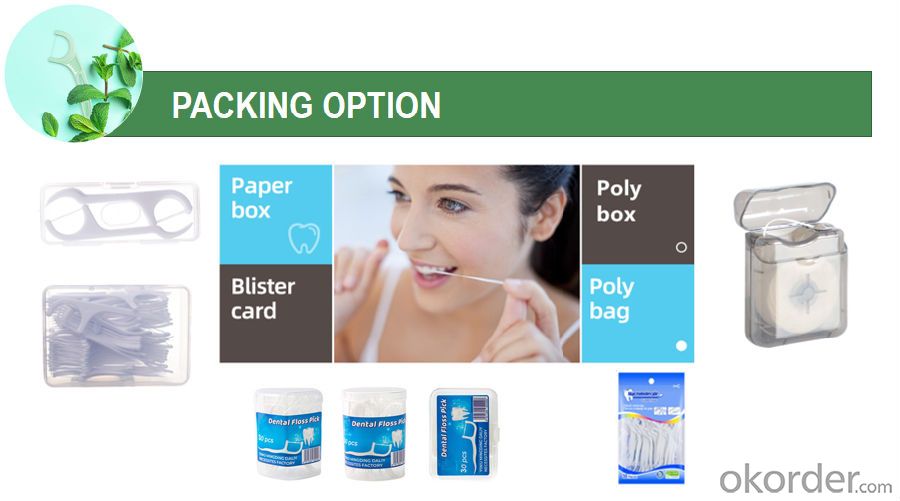

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

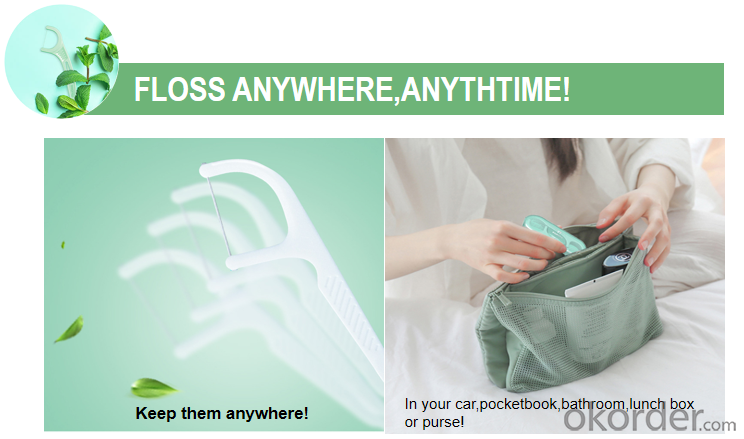

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

400D UHMWPE EXTRA STRONG FLOSS

Thin,strong,high resilience non-braching.Using supper smooth food

grade.UHMWPE floss ,not easy to stretch shred ,or break.

HIPS HANDLE

Food grade PS material,safe,solid,Antiskid.Comfortable to hold for

precise cleanig.

TOOTHPICK TAIL

Pointed-end remove foof residue effectivelly.Using food grade material,special

curved design toothpick,better for deep cleanig.

Made with super protected pick that

tuffloss that doesn’t stretch,shred or break. Protested pick that floss away

for use

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: Can medical plastic be used in 3D printing?

- Yes, medical plastic can be used in 3D printing. Medical-grade plastics such as polycarbonate, polypropylene, and polyethylene can be used to create customized medical devices, implants, and prototypes through the 3D printing process. These plastics are biocompatible, sterilizable, and meet the necessary regulatory standards for use in the medical field.

- Q: What are the considerations for using medical plastic in microfluidics?

- There are several important considerations for using medical plastic in microfluidics. Firstly, the biocompatibility of the plastic material is crucial to ensure that it does not interact negatively with biological samples or cells. Additionally, the material should exhibit low protein adsorption and minimal leaching of potentially harmful substances. The transparency and optical properties of the plastic are also important for visualizing and analyzing fluid flow within the microchannels. The mechanical properties, such as flexibility and durability, should be suitable for fabrication processes and long-term use. Finally, the ease of manufacturing, cost-effectiveness, and availability of the medical plastic should also be taken into account when selecting a material for microfluidic applications.

- Q: What about the surface of plastic shell for medical instruments?

- Plastic surface treatment methods for medical instruments are available:Forming, drilling, deburring, cleaning, spraying (screen printing, printing), electroplating.In addition to the non-toxic precipitation, no excessive RHOS, when necessary, to achieve durable structural requirements, and other general plastic treatment methods are the same.

- Q: How does medical plastic help in reducing the risk of contamination during medication administration?

- Medical plastic helps in reducing the risk of contamination during medication administration by providing a sterile and safe environment for storing, dispensing, and delivering medications. Plastic containers and packaging are designed to be airtight and tamper-proof, preventing any external contaminants from entering the medication. Additionally, plastic devices such as syringes, IV bags, and catheters are often single-use, minimizing the chances of cross-contamination between patients. These plastic materials are also easy to clean and disinfect, ensuring proper hygiene standards are maintained throughout the medication administration process.

- Q: How does medical plastic help in wound closure?

- Medical plastic helps in wound closure by providing a sterile and protective barrier over the wound. It can be shaped and customized to fit various wound sizes and shapes, ensuring a snug and secure closure. The plastic helps to keep out bacteria and other contaminants, reducing the risk of infection. Additionally, it promotes a moist wound healing environment, which accelerates the healing process and minimizes scarring.

- Q: Can medical plastics be used in ophthalmic applications?

- Yes, medical plastics can be used in ophthalmic applications. Ophthalmic applications, such as contact lenses, intraocular lenses, and surgical instruments, often require materials that are biocompatible, transparent, and have good mechanical properties. Medical plastics, such as silicone and hydrogel-based materials, meet these requirements and are commonly used in ophthalmic devices and procedures.

- Q: What kind of plastic is used for environmental protection materials?

- The utility model has the advantages of convenient storage and transportation, as long as the utility model has the advantages of dry drying, no need of avoiding light and wide application range, and not only can be used for agricultural film and packaging bags, but also can be widely used in the medical field. With the development of modern biological technology, biodegradable plastics have been paid more and more attention and become a new hot spot of research and development.

- Q: Are there any concerns about the mechanical strength of medical plastics?

- Yes, there are concerns about the mechanical strength of medical plastics. While medical plastics have numerous advantages such as being lightweight and easily molded, their mechanical strength can sometimes be compromised. This is especially true in applications where the plastic needs to withstand high stress or pressure. To address these concerns, manufacturers and engineers need to carefully select the appropriate type of plastic and design it to meet the specific mechanical requirements of the medical device or component. Regular testing and quality control measures are also crucial to ensure the mechanical strength and reliability of medical plastics in various healthcare settings.

- Q: What are the factors to consider when selecting a medical plastic for a specific application?

- When selecting a medical plastic for a specific application, several factors need to be considered. These include the material's biocompatibility, sterilization compatibility, chemical resistance, mechanical properties, and regulatory compliance. Biocompatibility ensures that the plastic doesn't cause any adverse reactions when in contact with living tissues. Sterilization compatibility is important to ensure that the plastic can withstand the chosen sterilization method without degradation. Chemical resistance ensures that the plastic remains stable when exposed to various chemicals in the medical environment. Mechanical properties such as strength, flexibility, and transparency should be suitable for the intended use. Lastly, regulatory compliance ensures that the plastic meets the necessary standards and regulations for medical devices.

- Q: What are the advantages of using medical plastic in healthcare?

- There are several advantages of using medical plastic in healthcare. Firstly, medical plastics are lightweight and flexible, making them easy to handle and use in various medical devices and equipment. Secondly, they are resistant to chemicals, which is crucial for maintaining sterility and preventing contamination in healthcare settings. Additionally, medical plastics can be molded into different shapes and sizes, allowing for customization and precise fit in medical devices like prosthetics or implants. Moreover, medical plastics are generally non-reactive and biocompatible, minimizing the risk of allergic reactions or tissue rejection when used in direct contact with the body. Lastly, medical plastics are cost-effective compared to other materials, making them a practical choice for healthcare institutions seeking efficient solutions. Overall, the advantages of using medical plastic in healthcare include versatility, safety, and affordability.

Send your message to us

Dental Floss Hot Sales Factor Price Wholesale Price High Quality ISO CE FDA Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords