Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand OEM/Ok Floss

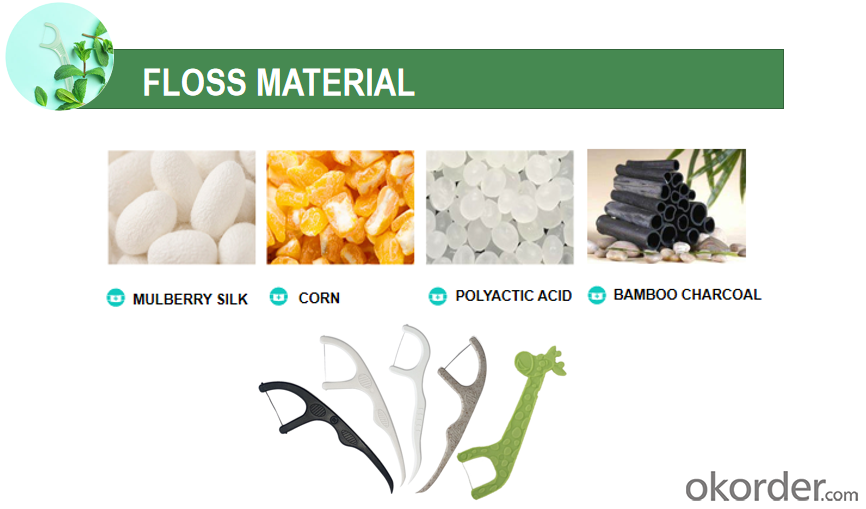

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

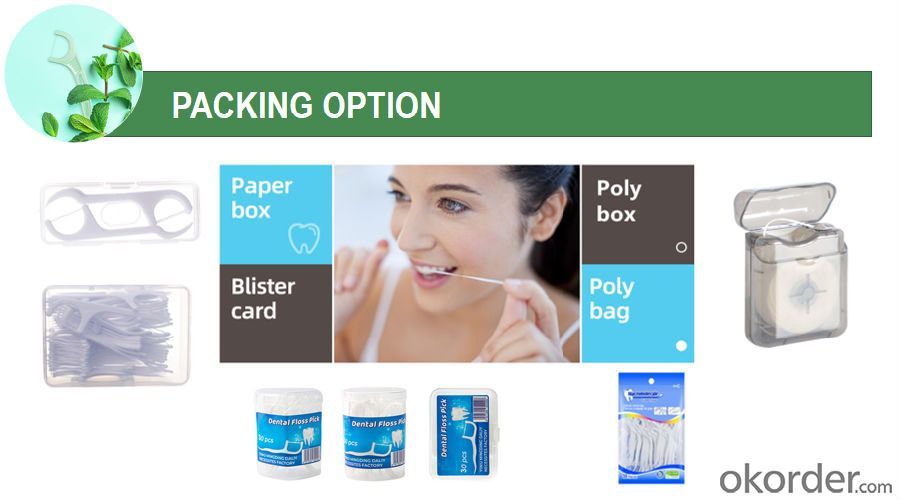

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How does medical plastic contribute to the development of tele-audiology technologies?

- Medical plastic plays a crucial role in the development of tele-audiology technologies by providing the necessary materials for the production of various components. It allows for the creation of lightweight, durable, and biocompatible devices such as ear molds, hearing aid shells, and diagnostic tools. These plastic materials enable the integration of technology in tele-audiology devices, ensuring accurate sound transmission, comfortable fit, and overall functionality.

- Q: What are the factors affecting the biocompatibility of medical plastic?

- Some of the factors affecting the biocompatibility of medical plastic include the chemical composition of the plastic material, its surface properties, the release of potentially toxic substances, its mechanical properties, and its ability to support the growth of bacteria or other microorganisms. Additionally, factors such as the duration and frequency of exposure to the plastic, the size and shape of the plastic device, and the specific biological environment in which it is used can also influence its biocompatibility.

- Q: How is medical plastic used in orthopedic implants?

- Medical plastic is used in orthopedic implants as it offers several advantages such as biocompatibility, durability, and flexibility. It is commonly used in joint replacements, bone plates, screws, and other devices to provide support and stability to damaged or diseased bones. Additionally, medical plastic can be molded into various shapes and sizes, allowing for customized implants that fit specific patient needs.

- Q: How are medical plastics used in diagnostic equipment?

- Medical plastics are used in diagnostic equipment in a variety of ways. They are commonly used to manufacture components such as tubing, connectors, and containers that are crucial for sample collection, storage, and transportation. Medical plastics are also used in the production of diagnostic tools like test kits, laboratory supplies, and imaging equipment. These plastics provide the necessary properties such as durability, chemical resistance, and transparency required for accurate diagnosis and patient safety. Additionally, medical plastics enable the development of disposable diagnostic devices, reducing the risk of cross-contamination and improving overall hygiene in medical settings.

- Q: Are there any regulations for the use of additives in medical plastics?

- Yes, there are regulations in place for the use of additives in medical plastics. These regulations ensure the safety and efficacy of medical devices and equipment by outlining specific requirements and restrictions on the types and amounts of additives that can be used. These regulations also cover issues such as biocompatibility, sterilization, and labeling of medical plastics.

- Q: What are the considerations for selecting medical plastic for minimally invasive surgery?

- When selecting medical plastic for minimally invasive surgery, there are several important considerations to keep in mind. First and foremost, the chosen plastic material must be biocompatible to ensure it does not cause any adverse reactions or harm to the patient's body. It should be capable of withstanding sterilization processes without losing its structural integrity or releasing any toxic substances. Additionally, the plastic should possess desirable mechanical properties, such as flexibility, durability, and resistance to wear and tear, to enable the creation of precise and reliable surgical instruments. Lastly, the material should be able to bond securely with other components or materials used in the surgical devices to ensure their overall functionality and safety during surgery.

- Q: Can medical plastics be used in respiratory applications?

- Yes, medical plastics can be used in respiratory applications. These plastics are often used to manufacture various respiratory devices such as oxygen masks, nebulizers, and ventilator components. They are chosen for their biocompatibility, flexibility, and resistance to sterilization methods. Medical plastics ensure safe and effective respiratory treatments for patients.

- Q: How is medical plastic used in wound drainage systems?

- Medical plastic is used in wound drainage systems to create flexible and sterile tubes or catheters that can be inserted into the wound to drain excess fluid or blood. These plastic materials are biocompatible, preventing any adverse reactions or infections. They are designed to be easily inserted and removed, providing a safe and effective method for managing wound drainage and promoting healing.

- Q: What are the guidelines for the maintenance of medical plastic products?

- The guidelines for the maintenance of medical plastic products typically include regular cleaning using mild soap and water, avoiding abrasive materials or harsh chemicals that may damage the plastic, and storing the products in a clean and dry environment to prevent contamination. Additionally, following manufacturer instructions and seeking professional advice, if necessary, can help ensure proper maintenance and longevity of medical plastic products.

- Q: How does the production of medical plastics impact the environment?

- The production of medical plastics has a significant impact on the environment. It involves the extraction and processing of fossil fuels, which contribute to greenhouse gas emissions and climate change. Additionally, the manufacturing process releases various toxic chemicals and pollutants into the air, water, and soil, leading to pollution and degradation of natural ecosystems. Moreover, the disposal of medical plastics, often through incineration or landfilling, further contributes to pollution and poses risks to human and animal health. Overall, the production and disposal of medical plastics have negative implications for the environment and call for sustainable alternatives and improved waste management practices.

Send your message to us

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches