Dental Flossing Eco Bamboo Charcoal Strong Teeth Floss Cleaner Picks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Flossing Eco Bamboo Charcoal Strong Teeth Floss Cleaner Picks

| Brand | OEM/Ok Floss |

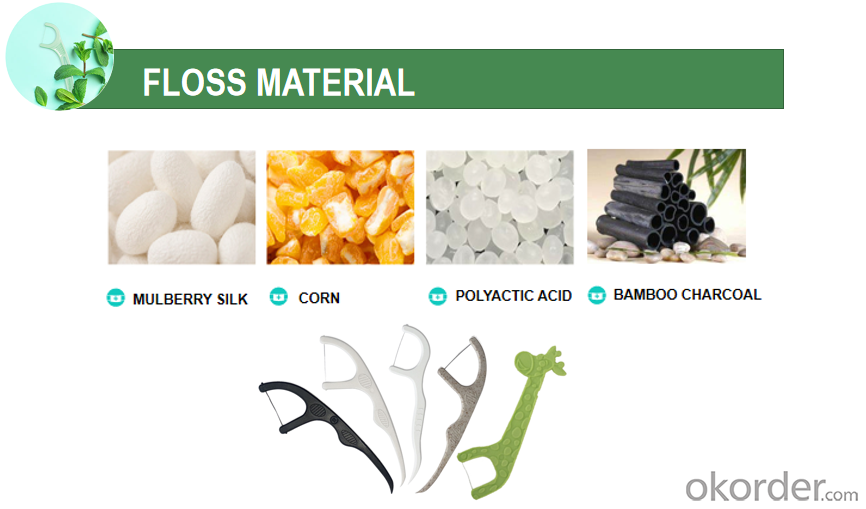

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

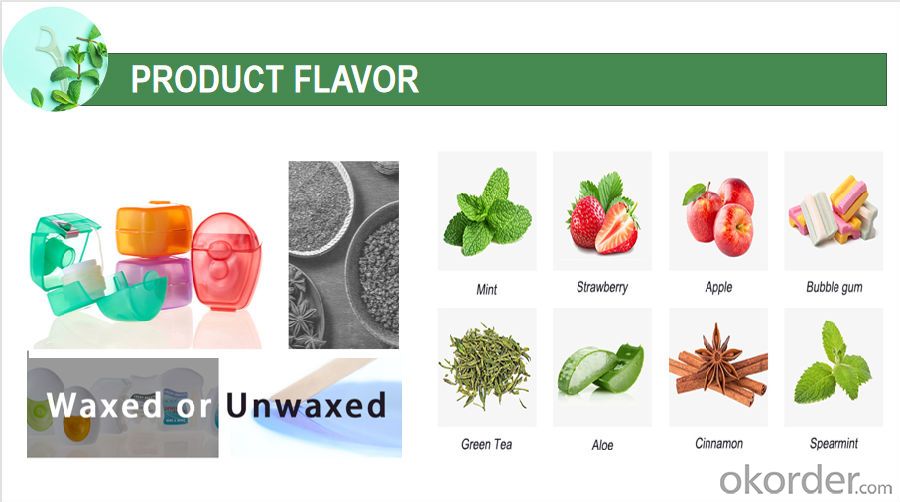

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

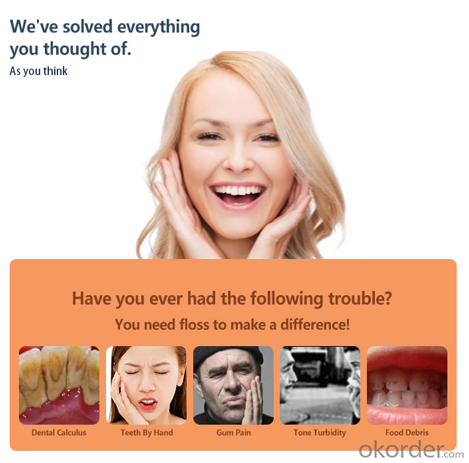

Why we need use dental floss??

Because it can reduce your chances of 60% of adjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.Flossing your teeth in the right way will

remove food particles and growing plaque from spots where your toothbrush can’t reach, generally between

your teeth and under the gumline.

FAQ

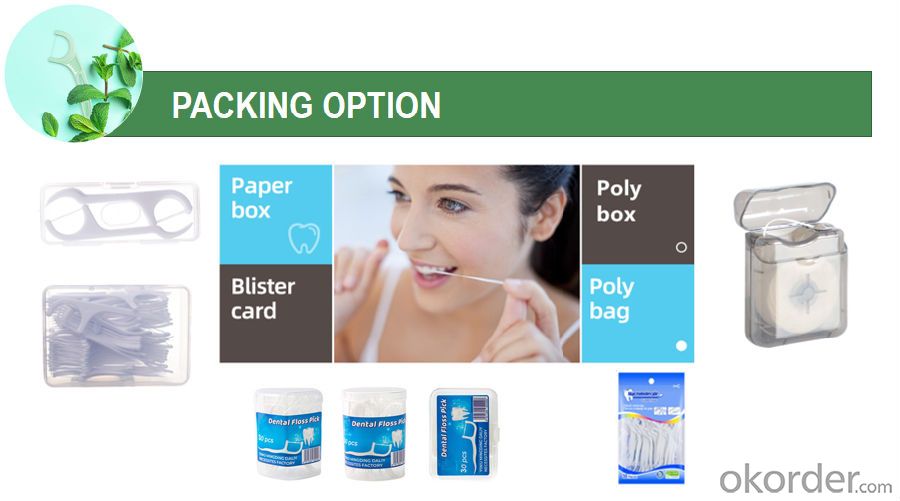

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q: What are the considerations for designing medical plastic parts for injection molding?

- When designing medical plastic parts for injection molding, several considerations must be taken into account. Firstly, the material used should be biocompatible and meet the necessary regulatory requirements for medical devices. Additionally, the part design should ensure proper functionality, ease of assembly, and compatibility with other components. It is important to consider factors such as wall thickness, draft angles, and gate location to ensure successful injection molding. Furthermore, the design should accommodate features like ribs, bosses, and snap fits to enhance structural integrity and functionality. Lastly, attention should be given to surface finish, ease of sterilization, and potential for contamination or bacterial growth.

- Q: Can I marinate salted duck eggs with a pp05 plastic bucket?

- Plastic formula, in addition to the resin, plastic additives also contain a variety of ingredients, such as fillers, plasticizers, stabilizers, lubricants, coloring agent, antistatic agent, foaming agent, flame retardant, crosslinking agent, etc..

- Q: What are the key properties to consider when selecting medical plastics?

- The key properties to consider when selecting medical plastics are biocompatibility, sterilization compatibility, chemical resistance, mechanical strength, and dimensional stability.

- Q: How do medical plastics contribute to the development of biosensors?

- Medical plastics play a crucial role in the development of biosensors by providing a versatile and biocompatible material for sensor fabrication. These plastics can be easily molded into complex shapes, allowing for the incorporation of various components such as electrodes, microfluidic channels, and sensing elements. Additionally, medical plastics offer excellent chemical resistance and stability, ensuring the durability and reliability of biosensors. Furthermore, the biocompatibility of medical plastics minimizes the risk of adverse reactions when the biosensors come into contact with biological fluids or tissues, making them ideal for implantable or wearable applications. Overall, medical plastics enable the design and production of innovative biosensors that can revolutionize medical diagnostics and monitoring.

- Q: What are the potential risks of using medical plastic?

- Some potential risks of using medical plastic include the leaching of harmful chemicals into the body, the possibility of allergic reactions or irritation, and the potential for bacterial contamination if not properly sterilized. Additionally, there may be concerns regarding the disposal and environmental impact of medical plastic waste.

- Q: Are there any potential risks associated with the release of toxic fumes from medical plastics?

- Yes, there are potential risks associated with the release of toxic fumes from medical plastics. When medical plastics are heated or burned, they can release harmful chemicals and gases, such as dioxins or volatile organic compounds (VOCs), which can pose health hazards to patients, healthcare workers, and the environment. Exposure to these toxic fumes can lead to respiratory problems, allergic reactions, and long-term health issues. Therefore, it is crucial to handle and dispose of medical plastics properly to minimize these risks.

- Q: What safety regulations apply to medical plastic?

- Safety regulations that apply to medical plastics include requirements for biocompatibility, sterilization compatibility, chemical resistance, and non-toxicity. These regulations ensure that medical plastics used in healthcare settings meet strict standards and do not pose any harm to patients or healthcare professionals.

- Q: How are medical plastics used in respiratory devices?

- Medical plastics are used in respiratory devices in several ways. For example, they are used in the manufacturing of components such as valves, connectors, and tubing, which are essential for the proper functioning of respiratory devices. Medical plastics are chosen for these applications due to their biocompatibility, durability, and flexibility, allowing for comfortable and safe use by patients. Additionally, medical plastics are often used in the construction of disposable masks and breathing chambers, ensuring hygiene and preventing the spread of infections.

- Q: Plastic gloves are several kinds of medical instruments?

- But for medical gloves, latex gloves, usually used in professional situations, such as the operation room, laboratory and other higher requirements on the health conditions of the place, has a certain flexibility, and more durable, but not resistant to corrosion of animal fats, animal fats exposed to corrosion, it is more important according to the statistics of 2%-17% of people will have different the degree of latex allergy.

- Q: How are medical plastics different from regular plastics?

- Medical plastics are specifically designed and manufactured to meet the unique requirements of the healthcare industry. They undergo rigorous testing and adhere to strict quality standards to ensure their safety and compatibility with medical devices and equipment. Unlike regular plastics, medical plastics are often sterilizable, biocompatible, and resistant to chemical degradation. They also have enhanced properties such as transparency, flexibility, and durability, making them suitable for various medical applications like implants, surgical instruments, and drug delivery systems.

Send your message to us

Dental Flossing Eco Bamboo Charcoal Strong Teeth Floss Cleaner Picks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords