Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

| Brand | OEM/Ok Floss |

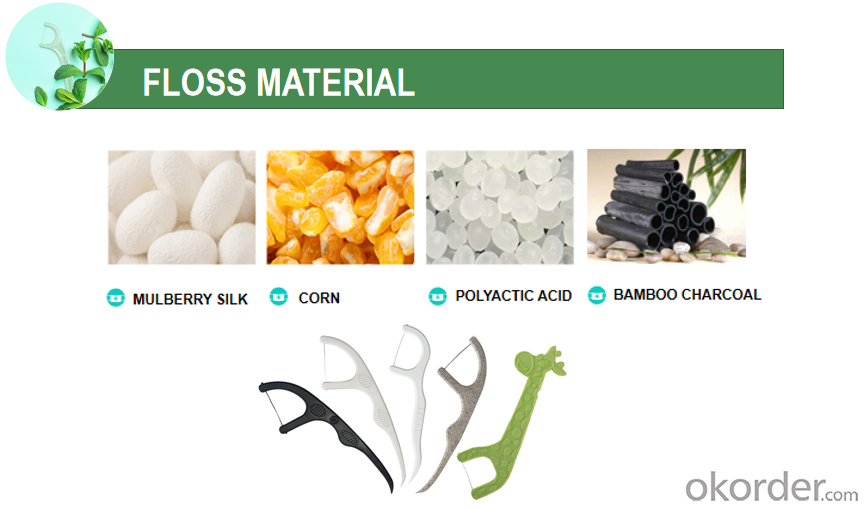

| Floss material | Bamboo Charcoal /OEM |

| Floss length | 7.4*2.2cm/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Black |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

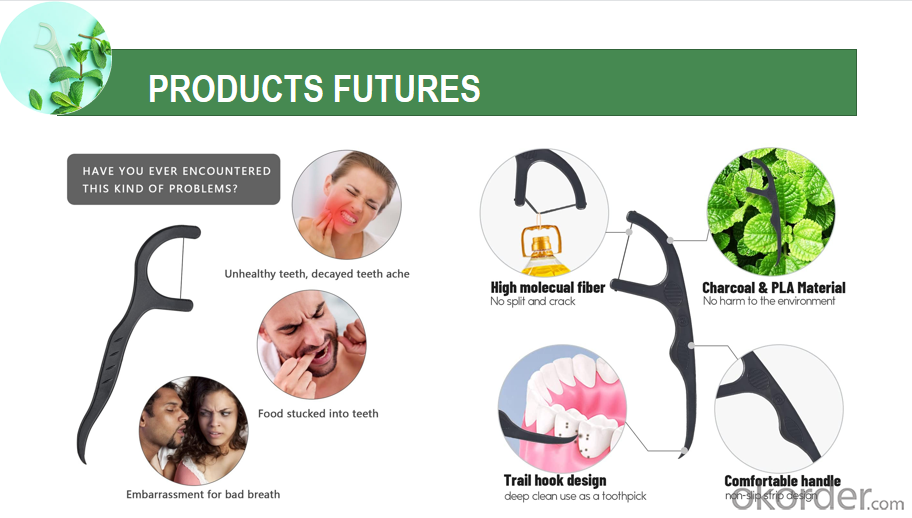

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OK FLOSS HELP YOUR ORAL CARE PROFESSIONAL OEM/ODM PROVIDER

Why we need use dental floss??

Because it can reduce your chances of 60% of adjacent dental caries and 70% of periodontal disease. It allows you to have a healthy tooth of your own at

the age of 80.Flossing your teeth in the right way will remove food particles and growing plaque from spots where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

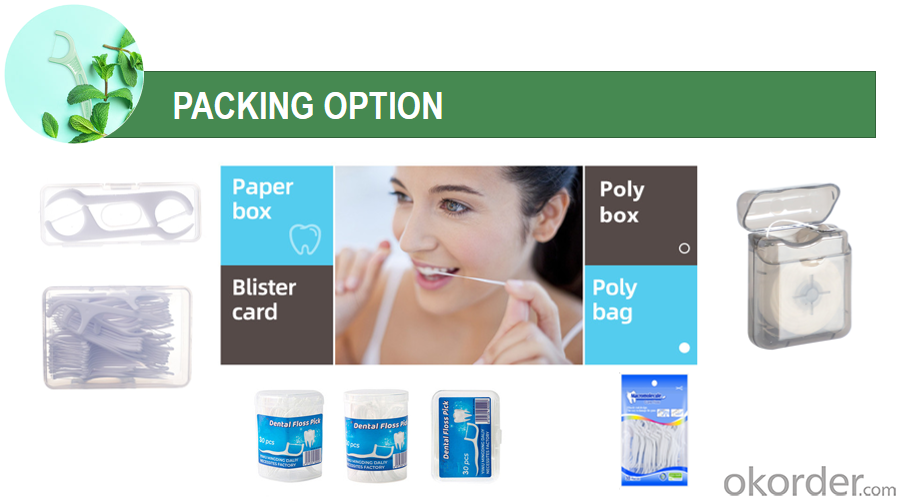

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: Are medical plastics resistant to fungal and bacterial growth?

- Yes, medical plastics are generally resistant to fungal and bacterial growth. They are designed to be non-porous and have antimicrobial properties that inhibit the growth of microorganisms, making them ideal for use in medical settings where cleanliness and infection control are critical.

- Q: Can medical plastics be colored or tinted?

- Yes, medical plastics can be colored or tinted. This allows them to be easily identified for different medical purposes or to match specific branding requirements.

- Q: Can medical plastic be used for long-term implantable devices?

- Yes, medical plastic can be used for long-term implantable devices. Medical-grade plastics, such as polyethylene, polyurethane, and silicone, are commonly used in the manufacturing of various long-term implantable medical devices. These materials are biocompatible, durable, and resistant to degradation, making them suitable for extended periods of implantation within the human body. However, specific factors such as device design, material selection, and patient-specific considerations should be taken into account to ensure the safety and efficacy of the implantable device.

- Q: What's the difference between PVC rubber and plain rubber?

- PVC, that is, poly chloride (with the green sound) ethylene, English abbreviation PVC (Polyvinyl chloride), is chloride monomer (vinyl chloride monomer (vinyl, monomer, referred to as VCM) in peroxide, azo compounds and other initiators;

- Q: What are the considerations for preventing the migration of additives from medical plastic?

- There are several considerations for preventing the migration of additives from medical plastic. Firstly, it is important to carefully select and test the additives used in the plastic, ensuring they comply with relevant regulatory standards and are suitable for medical applications. This includes evaluating their potential for migration and understanding their chemical composition and stability. Additionally, the choice of plastic material itself plays a crucial role. Medical-grade plastics with low permeability and good chemical resistance should be chosen to minimize the risk of additive migration. Understanding the interactions between the additives and the plastic matrix is essential to ensure long-term stability. Proper manufacturing processes and controls are also critical. It is important to maintain consistent processing conditions and avoid excessive heat, which can accelerate the migration of additives. Adequate quality control measures should be implemented to monitor and test the finished products for any potential migration. Regular monitoring and testing of the medical plastic throughout its lifecycle are necessary to ensure ongoing compliance and to detect any potential migration issues. This includes conducting extractable and leachable studies to identify and quantify any substances that may migrate from the plastic. Overall, a comprehensive approach that involves careful selection of additives, appropriate choice of plastic material, stringent manufacturing processes, and regular monitoring is crucial for preventing the migration of additives from medical plastic and ensuring the safety and efficacy of medical devices.

- Q: Are there any potential risks associated with the release of microplastics from medical plastics?

- Yes, there are potential risks associated with the release of microplastics from medical plastics. Microplastics, which are tiny plastic particles, can enter the environment and potentially contaminate water bodies, soil, and even the air. They have the potential to accumulate in living organisms, including marine life, and can pose a threat to ecosystems and human health. Furthermore, the long-term effects of microplastic exposure are not yet fully understood, which raises concerns about potential risks to both the environment and human well-being.

- Q: How long does it take to sterilize the autoclave?

- Because the pressure in the bottle is the same as that on the pressure gauge (just out of the bacteria), if it is deflated directly, it will burst the bottle.

- Q: Plastic compressor machine how much money the cheapest

- According to lubrication, can be divided into oil-free air compressor and oil lubrication compressor. According to the performance can be divided into: low-noise, variable frequency, explosion-proof and other air compressor.

- Q: What are the limitations of using medical plastics?

- There are several limitations associated with using medical plastics. Firstly, certain medical plastics may not be suitable for all medical applications due to their inability to withstand high temperatures or harsh chemicals. This can restrict their use in certain surgical procedures or sterilization methods. Secondly, medical plastics can potentially release harmful chemicals or leach additives into the body, which can cause adverse effects or reactions in patients. Additionally, the durability of medical plastics may vary, with some being prone to degradation over time or becoming brittle, which can compromise their effectiveness and safety. Moreover, the production and disposal of medical plastics can have negative environmental impacts, contributing to plastic waste and pollution. These limitations highlight the need for careful selection, testing, and regulation of medical plastics to ensure their safety, compatibility, and sustainability in healthcare settings.

- Q: What are the guidelines for the storage of medical plastic products?

- The guidelines for the storage of medical plastic products include maintaining a clean and dry environment, storing them separately from other materials, avoiding exposure to extreme temperatures, and following any specific instructions provided by the manufacturer. It is also important to regularly inspect the products for any signs of damage or deterioration.

Send your message to us

Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches