Long Lasting Insecticide Treated Mosquito Net for Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

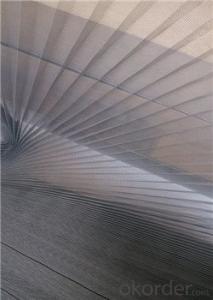

Introduction of Mosquito Net

This long lasting mosquito bed net is hooked on the ceiling and tucked under your mattress for overnight protection from bites. The deltamethrin treatment provides 4-5 years of protection, unlike permathrin which only lasts about 1 year. Insecticide treated mosquito nets, if used properly, are one of the best ways to prevent mosquitoes from biting and infecting individuals with malaria and other mosquito-borne diseases.

Details of Mosquito Net :

Lasts 4-5 years

Suitable for beds of all dimensions

For one or two people

Attaches to ceiling

Can be suspended from a ceiling

Pre-treated as per World Health Organization guidelines

Services of Mosquito Net :

Pre-sale services:

1.Various kinds of mosquito nets to choose from.

2.Any customized products can be satisfied according to your requirements.

3.Professional technicians engaged in each procedures.

Services during the sale:

1.Pre-checking and safeguarding products before delivery.

2.Providing solutions for any unexpected conditions involved.

After-sale services:

1.Assist customers on how to hang the exact mosquito nets.

2.Provided with instructions or vidoes of certain mosquito nets foldings.

3.24-hour Services.Contact us for any questions, we'd be gladly to follow.

Packaging & Delivery of Mosquito Net :

| Packaging Detail: | Individually packed into branded plastic bag,100 units per bale. |

| Delivery Detail: | 2 weeks after confirm order and payment |

FAQ of Mosquito Net:

1.Sample

We'd be gladly to send you the sample for free, but you need to pay for transport cost, and we will turn back this amount of money to you after orders issued.

2. MOQ

Our minimum order quantity for mosquito net is 1,000 pieces, and 500 kilograms for fleece fabric and mosquito net fabric.

3.Color, Size

Any color and any size is available as long as it's connected with mosquito nets.

- Q: How are medical plastics used in drug packaging?

- Medical plastics are commonly used in drug packaging due to their ability to provide a safe and sterile environment for medications. These plastics are used to manufacture various packaging components such as bottles, vials, blister packs, and containers. They help to protect the drugs from moisture, light, and air, ensuring their stability and effectiveness. Additionally, medical plastics are also used to create tamper-evident seals, ensuring the integrity and safety of the medication until it reaches the consumer.

- Q: How are medical plastics tested for quality and durability?

- Medical plastics are tested for quality and durability through a variety of methods. These include mechanical tests to assess strength, flexibility, and impact resistance, as well as chemical tests to evaluate resistance to various substances like solvents and disinfectants. Additionally, biocompatibility tests ensure that the plastics do not cause any adverse reactions when in contact with living tissues. Thorough quality control measures, including inspections and performance evaluations, are also conducted to ensure that medical plastics meet the required standards before being used in healthcare applications.

- Q: How are medical plastics used in wound care?

- Medical plastics are used in wound care in various ways. They are used to create dressings, bandages, and wound closure devices such as sutures and staples. These plastics are designed to be sterile, non-toxic, and compatible with the human body. They help protect the wound from infection, promote healing, provide support, and facilitate the removal of exudate (fluid) from the wound. Additionally, medical plastics can be used to create specialized wound care products such as negative pressure wound therapy devices and bioactive dressings that release medications to aid in the healing process.

- Q: Can medical plastics be used for long-term medical implants?

- Yes, medical plastics can be used for long-term medical implants. Medical-grade plastics such as polyethylene, polyurethane, and silicone have been successfully used in various long-term implantable devices such as joint replacements, pacemakers, and artificial heart valves. These plastics are biocompatible, durable, and resistant to degradation, making them suitable for long-term use within the human body. However, thorough testing and regulatory approvals are essential to ensure the safety and efficacy of such implants.

- Q: How do medical plastics contribute to the development of implantable devices?

- Medical plastics play a crucial role in the development of implantable devices by providing a wide range of properties that are essential for their success. These plastics are biocompatible, meaning they are non-toxic and do not elicit harmful reactions within the body. They also possess excellent mechanical strength and flexibility, allowing them to withstand the stresses and strains of the body's movements. Additionally, medical plastics can be engineered to have specific properties such as antimicrobial or drug-release capabilities, further enhancing the functionality of implantable devices. Overall, medical plastics enable the development of safe, effective, and durable implantable devices that significantly improve medical treatments and patient outcomes.

- Q: What are the factors that affect the biocompatibility of medical plastics?

- The factors that affect the biocompatibility of medical plastics include the chemical composition of the plastic, its surface characteristics, the presence of additives or impurities, its mechanical properties, and the duration of exposure to body tissues.

- Q: Can medical plastics be used in wound care products?

- Yes, medical plastics can be used in wound care products. They offer various benefits such as being lightweight, flexible, and sterile. Medical plastics are commonly used in wound dressings, bandages, sutures, and other wound care products to promote healing and protect wounds from infection.

- Q: What are the considerations for disposal of medical plastic products?

- Some considerations for the disposal of medical plastic products include ensuring proper segregation of waste, following local regulations and guidelines, implementing appropriate recycling or incineration methods, minimizing environmental impact, and maintaining patient and staff safety throughout the disposal process.

- Q: What are the manufacturing processes for medical plastics?

- The manufacturing processes for medical plastics typically involve injection molding, extrusion, blow molding, and thermoforming. These processes allow for the production of various medical devices and components, such as syringes, IV tubing, implantable devices, and packaging materials.

- Q: Can medical plastics be used in otorhinolaryngology applications?

- Yes, medical plastics can be used in otorhinolaryngology applications. Medical-grade plastics are commonly used in various devices and implants within the field of otorhinolaryngology, including ear tubes, nasal stents, and laryngeal masks. These plastics are chosen for their biocompatibility, durability, and ability to be shaped into complex designs that cater to specific anatomical requirements.

Send your message to us

Long Lasting Insecticide Treated Mosquito Net for Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords