Dental Floss Picks/Flossers With Flavor Land Animal Shape Colored For Kids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Picks/Flossers With Flavor Land Animal Shape Colored For Kids

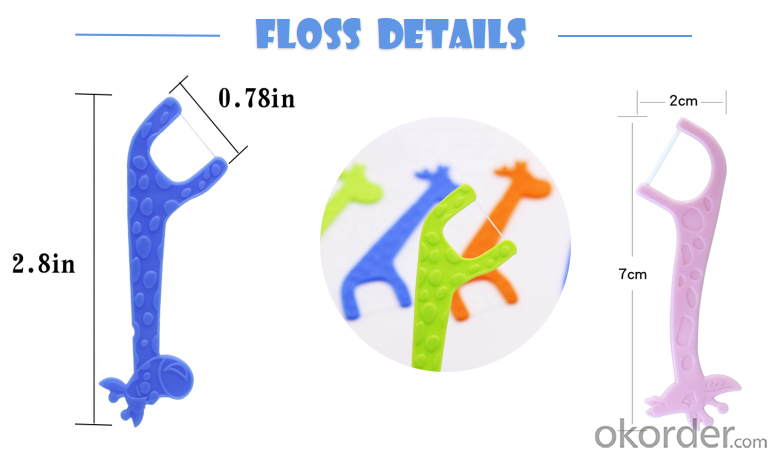

Brand OEM/Ok Floss Floss material UHMWPE,Charcal as customized Size Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm Wax Import germany wax/american wax/bee wax/candelilla wax/customized wax Flavor Mint / green tea / lemon / peach / fruit / aloe / gin Color Floss original color Floss original color Individual bulk PP bag/individual paper box/as customized Applications Family,Hotel,Travel,Supermarket Shape Bear,Giraffe,Cola Lead time 20-30days | |

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE |

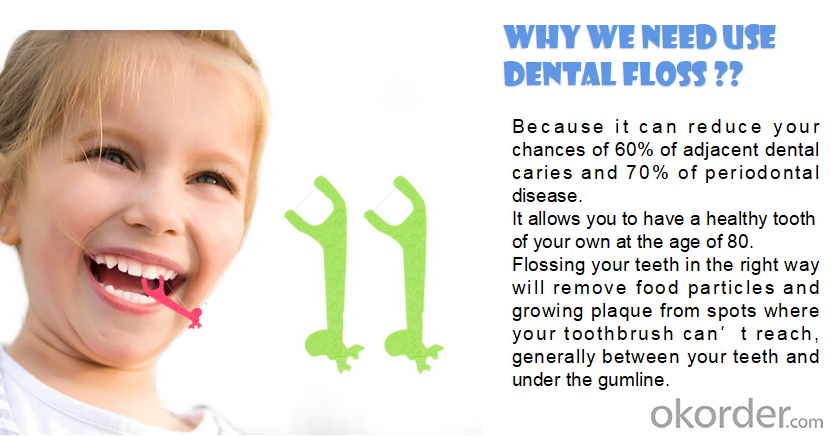

REDUCE ADJACENT DENTAL CARIES

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

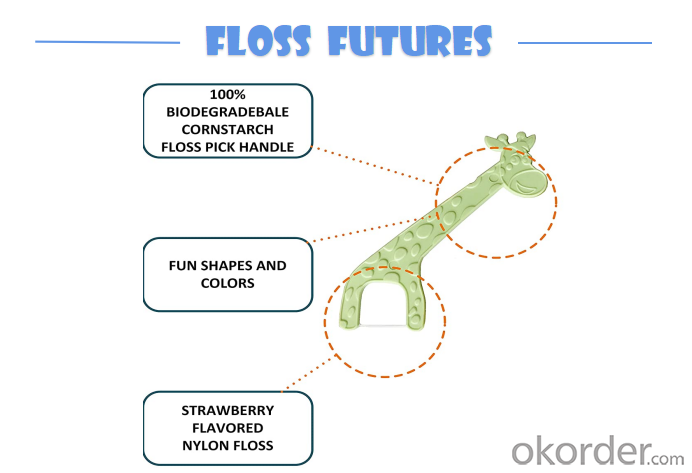

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS STRAWBERRY FLAVORED NYLON FLOSS

Easilly slips between teeth ,without shredding, to comfortably remove plaque and help prevent gum disease

&

Good looking design protect children to hurt themselves

DENTAL FLOSS DETAILS & SIZE

COMFORT HANDLE;FOOD-GRAD MATERIALL;DENTAL FOR KIDS;FIBER FLOSS

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

DENTAL FOR KIDS

FACTORY PRICE & OEM

CERTIFICATIONS FDA CE ISO FSC

DENTAL FLOSS

GLOBAL MARKETING SERVICES

&

LOGISTIC SERVICE

&

EXPORT CREDIT INSURANCE SERVICES

&

FINANCIAL SERVICES

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What kind of plastic is used in medical instruments? Can also be sterilized at high temperature

- Ethylene oxide is difficult to transport, so you can see the supply locally. If you do not have the ability to disinfect, you can also find medical equipment company oem.

- Q: What are the most common uses of medical plastics in veterinary medicine?

- Some of the most common uses of medical plastics in veterinary medicine include the production of syringes, catheters, surgical instruments, implantable devices, and various types of packaging for medications. These plastics offer benefits such as durability, flexibility, and biocompatibility, making them suitable for a wide range of applications in veterinary healthcare.

- Q: What are the considerations for preventing leaching of chemicals from medical plastic?

- There are several key considerations for preventing leaching of chemicals from medical plastic. Firstly, selecting the appropriate type of plastic that is known to have low leaching potential is crucial. This involves carefully evaluating the chemical composition and properties of the plastic material to ensure it is compatible with the intended use and does not contain harmful additives. Secondly, proper manufacturing and processing techniques must be adopted to minimize the risk of chemical leaching. This includes using clean and controlled environments, employing suitable sterilization methods that do not degrade the plastic, and avoiding exposure to high temperatures or aggressive chemicals during production. Thirdly, regular testing and quality control measures should be implemented to ensure that the medical plastic products comply with the necessary regulatory standards. This involves conducting leachability studies to assess the potential release of chemicals from the plastic, as well as monitoring the stability and integrity of the material over time. Furthermore, proper storage and handling practices are important considerations. Medical plastic should be stored in appropriate conditions, away from direct sunlight, extreme temperatures, and incompatible substances that could potentially interact and cause leaching. Lastly, thorough cleaning and maintenance protocols should be established to prevent the buildup of residues or contaminants on the plastic surface, which could potentially lead to leaching. Regular inspection and cleaning of medical plastic devices and equipment, using compatible cleaning agents and methods, can help minimize the risk of chemical leaching and ensure patient safety.

- Q: What are the considerations for ensuring the flexibility and elasticity of medical plastic materials?

- There are several important considerations for ensuring the flexibility and elasticity of medical plastic materials. Firstly, the choice of polymer is crucial, as different types of plastics have varying degrees of flexibility and elasticity. It is important to select a polymer that can be molded or shaped easily without compromising its mechanical properties. Secondly, the manufacturing process plays a significant role in determining the flexibility and elasticity of medical plastic materials. Techniques such as injection molding or extrusion can be used to create plastic products with specific flexibility and elasticity characteristics. Additionally, the design of the medical device or product should be carefully considered. Factors such as wall thickness, geometry, and the presence of reinforcing additives can all influence the flexibility and elasticity of the plastic material. Moreover, the choice of additives or fillers can also impact the flexibility and elasticity of medical plastics. Plasticizers, for example, can be added to increase flexibility, while reinforcing agents can enhance elasticity. It is important to carefully select and balance the additives to achieve the desired properties without compromising safety or biocompatibility. Lastly, thorough testing and quality control measures should be implemented to ensure that the flexibility and elasticity of medical plastic materials meet the required standards and specifications. This may involve conducting mechanical tests, such as tensile or flexural testing, to assess the material's performance under different conditions. By considering these factors, manufacturers can ensure that medical plastic materials possess the necessary flexibility and elasticity for their intended applications in the healthcare industry.

- Q: Medical alcohol, 95 degrees freezer, refrigerated glass bottle or plastic bottle safe?

- If you have to put the refrigerator, glass bottle is best, plastic bottles worry about a long time will be corrosive, but in fact it is safe.

- Q: What are the factors that affect the impact resistance of medical plastics?

- The factors that affect the impact resistance of medical plastics include the material composition, molecular structure, processing techniques, and the presence of additives or reinforcements. Additionally, the temperature and environmental conditions, such as exposure to chemicals or UV radiation, can also influence the impact resistance of medical plastics.

- Q: What are the ingredients in a plastic foam box?

- The main raw material of foam polystyrene, talcum powder, calcium stearate, butane etc..

- Q: Can medical plastics be used in wound care products?

- Yes, medical plastics can be used in wound care products. They offer several advantages such as being lightweight, flexible, and sterile. Medical plastics like silicone, polyurethane, and hydrocolloids are commonly used for creating wound dressings, adhesive tapes, and other wound care products. These materials promote healing, provide a barrier against infection, and offer comfort to patients.

- Q: Is it made of plastic, titanium or metal titanium?

- If the medical institution and its medical personnel are at fault, the medical institution shall bear the liability for compensation when the patient is injured in the diagnosis and treatment.

- Q: Where can I find the exact material for jet writing? Plastic material

- Medical devices such as orthopedic prostheses, artificial nose, eye, light pipe, medical denture powder. Stationery, daily necessities, such as penholder, drawing tools, teaching models, specimens, lamps, buttons, hairpins, candy trays, etc.. Molding by injection molding, extrusion, casting, casting, coating, bonding and other forming processes.

Send your message to us

Dental Floss Picks/Flossers With Flavor Land Animal Shape Colored For Kids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords