Polyethylene Long Lasting Insecticide Treated Mosquito Nets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

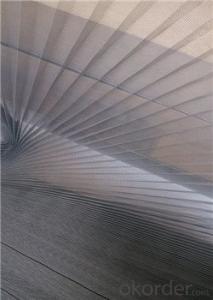

Introduction of Mosquito Net

This long lasting mosquito bed net is hooked on the ceiling and tucked under your mattress for overnight protection from bites. The deltamethrin treatment provides 4-5 years of protection, unlike permathrin which only lasts about 1 year. Insecticide treated mosquito nets, if used properly, are one of the best ways to prevent mosquitoes from biting and infecting individuals with malaria and other mosquito-borne diseases.

Details of Mosquito Net :

Lasts 4-5 years

Suitable for beds of all dimensions

For one or two people

Attaches to ceiling

Can be suspended from a ceiling

Pre-treated as per World Health Organization guidelines

Services of Mosquito Net :

Pre-sale services:

1.Various kinds of mosquito nets to choose from.

2.Any customized products can be satisfied according to your requirements.

3.Professional technicians engaged in each procedures.

Services during the sale:

1.Pre-checking and safeguarding products before delivery.

2.Providing solutions for any unexpected conditions involved.

After-sale services:

1.Assist customers on how to hang the exact mosquito nets.

2.Provided with instructions or vidoes of certain mosquito nets foldings.

3.24-hour Services.Contact us for any questions, we'd be gladly to follow.

Packaging & Delivery of Mosquito Net :

| Packaging Detail: | Individually packed into branded plastic bag,100 units per bale. |

| Delivery Detail: | 2 weeks after confirm order and payment |

FAQ of Mosquito Net:

1.Sample

We'd be gladly to send you the sample for free, but you need to pay for transport cost, and we will turn back this amount of money to you after orders issued.

2. MOQ

Our minimum order quantity for mosquito net is 1,000 pieces, and 500 kilograms for fleece fabric and mosquito net fabric.

3.Color, Size

Any color and any size is available as long as it's connected with mosquito nets.

- Q: Are there any limitations to using medical plastics?

- Yes, there are limitations to using medical plastics. Some limitations include the risk of leaching harmful substances into the body, potential for allergic reactions, limited heat resistance, and difficulty in sterilization. Additionally, medical plastics may not be suitable for certain applications that require high strength or biocompatibility.

- Q: What are the characteristics of medical plastics that make them suitable for medical devices?

- Medical plastics are specifically designed and manufactured to possess certain characteristics that make them highly suitable for medical devices. These characteristics include biocompatibility, sterilizability, chemical resistance, durability, flexibility, transparency, and ease of processing. These properties ensure that medical plastics are safe, reliable, and able to withstand the rigorous demands of the healthcare industry, making them ideal for a wide range of medical device applications.

- Q: How do medical plastics affect the performance of medical equipment?

- Medical plastics play a crucial role in enhancing the performance of medical equipment. These plastics are lightweight, durable, and resistant to chemicals, making them ideal for use in medical devices. Their flexibility allows for intricate designs and ease of manufacturing, enabling the creation of complex equipment. Moreover, medical plastics are biocompatible, reducing the risk of adverse reactions within the body. Overall, medical plastics positively impact the performance, functionality, and safety of medical equipment.

- Q: How are medical plastics used in drug delivery systems?

- Medical plastics are used in drug delivery systems in various ways. They are often used to create containers and packaging for medications, such as vials, bottles, and blister packs. These plastics are chosen for their ability to provide a sterile and safe environment for the drugs, protecting them from contamination and degradation. Additionally, medical plastics are used to manufacture devices like syringes, inhalers, and pumps that are used to administer drugs to patients. These devices are designed to be precise, reliable, and easy to use, ensuring accurate and efficient drug delivery.

- Q: How do medical plastics contribute to the development of telehealth sensors?

- Medical plastics play a crucial role in the development of telehealth sensors by providing essential properties such as biocompatibility, durability, and flexibility. These plastics are used to create components and housings for telehealth sensors, ensuring safe and reliable operation. Additionally, medical plastics enable the miniaturization of sensors, allowing for more compact and wearable devices that can be easily integrated into telehealth systems.

- Q: How do medical plastics contribute to cost savings in healthcare?

- Medical plastics contribute to cost savings in healthcare in several ways. Firstly, they are lightweight and durable, reducing the need for frequent replacements, which lowers overall costs. Secondly, medical plastics are often used in disposable products, such as syringes and gloves, eliminating the need for sterilization and reducing the risk of infections, thus decreasing healthcare-associated costs. Additionally, plastics can be easily mass-produced, making them cost-effective for large-scale manufacturing of medical devices and equipment. Lastly, medical plastics can be engineered to have specific properties, such as antimicrobial coatings, which can help prevent contamination and reduce the need for costly interventions. Overall, the use of medical plastics helps streamline healthcare processes, improve patient safety, and ultimately result in cost savings for the healthcare system.

- Q: How is medical plastic used in wound drainage systems?

- Medical plastic is used in wound drainage systems to create flexible and sterile tubes or catheters that can be inserted into the wound to drain excess fluid or blood. These plastic materials are biocompatible, preventing any adverse reactions or infections. They are designed to be easily inserted and removed, providing a safe and effective method for managing wound drainage and promoting healing.

- Q: How is medical plastic used in drug delivery systems?

- Medical plastic is commonly used in drug delivery systems to ensure the safe and effective administration of medications. It is used to manufacture various components such as syringes, vials, IV bags, and inhalers, which are essential in delivering drugs to patients. Medical plastic is preferred due to its biocompatibility, durability, and ability to prevent contamination. It helps in maintaining the sterility and stability of drugs, enabling precise dosing and controlled release. Additionally, medical plastic can be engineered to have specific properties, such as controlled permeability, which is crucial for transdermal patches or sustained-release implants. Overall, medical plastic plays a vital role in drug delivery systems by enhancing patient safety and treatment efficacy.

- Q: What are the most common uses of medical plastics in anesthesiology?

- Medical plastics are commonly used in anesthesiology for various purposes, including the manufacturing of anesthesia masks, endotracheal tubes, laryngeal masks, and IV catheters. These plastic devices are essential for providing safe and effective anesthesia delivery during surgical procedures, ensuring patient comfort and maintaining airway control.

- Q: What are the limitations of using medical plastics in healthcare?

- One limitation of using medical plastics in healthcare is the potential for leaching of harmful chemicals into the body. Some plastics contain additives, such as phthalates or bisphenol A (BPA), which have been linked to adverse health effects. Additionally, the disposal of medical plastics can present environmental challenges as they are often not easily recyclable and contribute to plastic waste. Furthermore, medical plastics may not possess the same strength and durability as other materials, making them more prone to breakage or degradation over time. Overall, while medical plastics have their benefits, it is crucial to consider these limitations and explore alternative materials that are safer and more sustainable for healthcare applications.

Send your message to us

Polyethylene Long Lasting Insecticide Treated Mosquito Nets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords