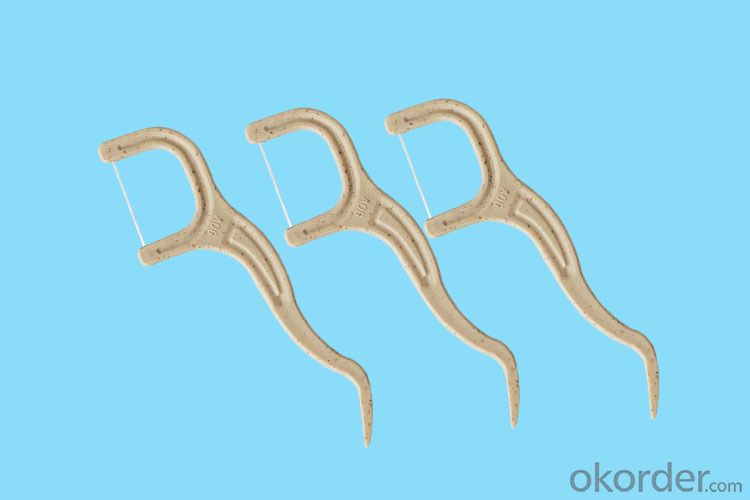

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

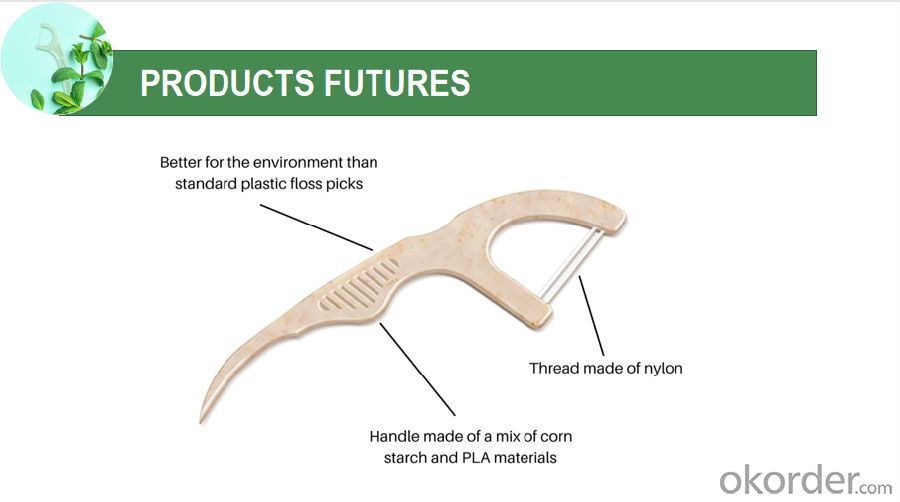

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

| Brand | OEM/Ok Floss |

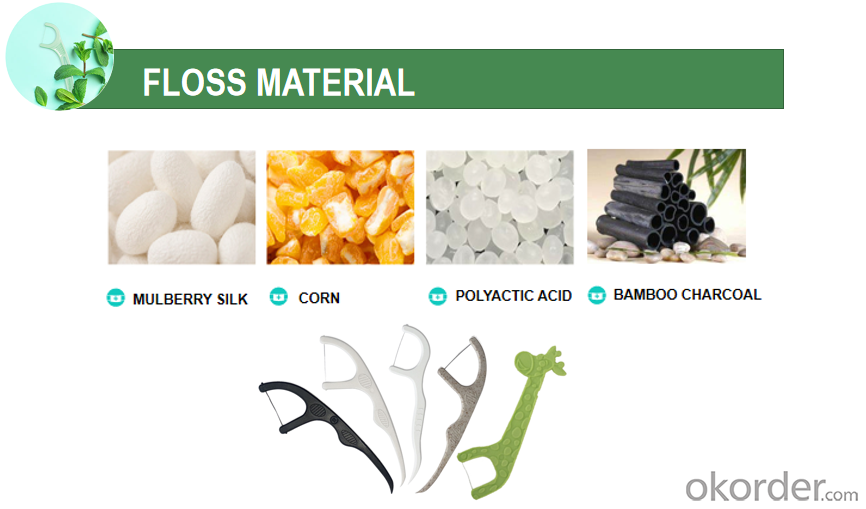

| Floss material | UHMWPE/PTFE+Straw |

| Floss length | 7.4*2.2cm/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

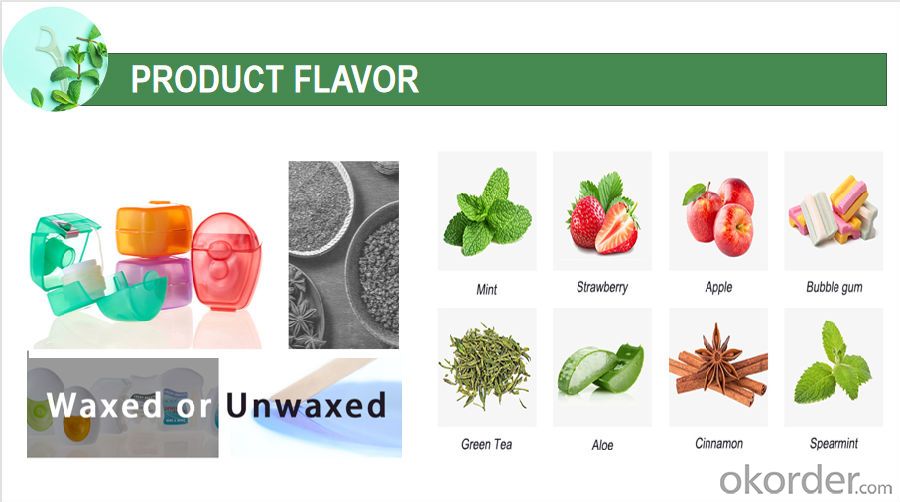

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

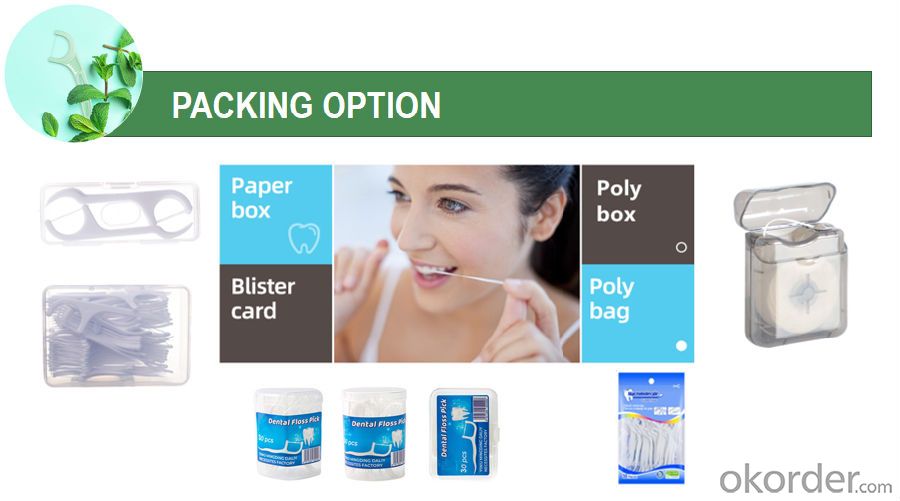

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What are the trends in medical plastic technology?

- Some of the trends in medical plastic technology include the development of biocompatible and bioresorbable materials, advancements in 3D printing for personalized medical devices, the use of antimicrobial plastics to reduce infections, and the integration of smart technology into medical plastic products for improved monitoring and diagnostics.

- Q: How does medical plastic contribute to the development of rehabilitation devices?

- Medical plastic contributes to the development of rehabilitation devices by providing lightweight, durable, and hypoallergenic materials that are essential for creating comfortable and functional devices. These plastics are easily molded into various shapes, allowing for the customization of rehabilitation devices to fit individual patient needs. Additionally, medical plastics are resistant to moisture and chemicals, making them suitable for devices that require frequent cleaning and sterilization. Overall, medical plastic plays a crucial role in enhancing the effectiveness and usability of rehabilitation devices, ultimately aiding in the recovery and rehabilitation process for patients.

- Q: How do medical plastics impact patient care?

- Medical plastics play a crucial role in enhancing patient care in various ways. They offer numerous benefits such as reducing the risk of infection through their antimicrobial properties, facilitating better sterilization practices, and providing a safer environment for patients. Additionally, medical plastics allow for the development of innovative medical devices, such as prosthetics and implants, which improve patient mobility and quality of life. Furthermore, these materials are lightweight, durable, and flexible, making them ideal for disposable medical equipment, reducing the risk of cross-contamination. Overall, medical plastics contribute significantly to enhancing patient care by promoting safety, innovation, and infection control in healthcare settings.

- Q: Can alcohol be sterilized in a plastic tub?

- If the immersion method, in order to achieve satisfactory disinfection effect, the need to fill the barrel of alcohol, which may waste too much. Better to wipe cloth (gauze) with alcohol soaked, wipe the wall with a cloth, repeated 2~3 times.

- Q: How do medical plastics impact the design of medical equipment?

- Medical plastics have a significant impact on the design of medical equipment due to their unique properties. These materials provide versatility, durability, and biocompatibility, allowing designers to create complex and precise equipment that is safe and reliable for patients. Medical plastics also enable the production of lightweight and cost-effective devices, which is crucial in the healthcare industry. Additionally, these plastics can be molded into various shapes and sizes, allowing for customization and innovation in medical equipment design.

- Q: What are the properties of medical plastic?

- Medical plastics have several important properties that make them suitable for use in the healthcare industry. Firstly, they are biocompatible, meaning they do not harm living tissue and can be safely used in contact with the human body. They are also sterilizable, allowing for proper disinfection and prevention of infection transmission. Additionally, medical plastics are lightweight and durable, making them convenient for use in medical devices and equipment. They possess excellent chemical resistance and can withstand exposure to various cleaning agents and drugs. Lastly, medical plastics can be molded into complex shapes, allowing for the production of customized medical products.

- Q: What color plastic bag do you use for medical garbage?

- The medical garbage is yellow and has the sign of medical garbage, and the living garbage is black.

- Q: Can medical plastics be used in prosthetics or orthotics?

- Yes, medical plastics can be used in prosthetics or orthotics. These plastics are often lightweight, durable, and biocompatible, making them suitable for use in these medical devices. They can be used to create custom-fit prosthetic limbs or orthotic braces that provide support and functionality to individuals with limb deficiencies or musculoskeletal conditions.

- Q: Can medical plastics be used in psychiatry applications?

- Yes, medical plastics can be used in psychiatry applications. They are commonly used in the manufacturing of devices like pill dispensers, syringes, and injection pens used in psychiatric treatment. Additionally, medical plastics are utilized in the production of various mental health-related equipment such as sleep apnea masks, electroencephalography (EEG) electrodes, and biofeedback sensors. These plastic materials are chosen for their durability, biocompatibility, and ease of sterilization, making them suitable for psychiatric applications.

- Q: What are the factors that affect the chemical resistance of medical plastics?

- The factors that affect the chemical resistance of medical plastics include the type and concentration of the chemical, temperature, exposure time, surface finish of the plastic, and the presence of additives or fillers in the plastic material.

Send your message to us

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords