Hot selling medical grade 0.2/0.25/0.3mm transparent PVC / PVDC film for pill blister packaging

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Transparent PVC/PVDC film is widely used in pharmaceutical packaging due to its high transparency and good barrier properties. Especially for blister packaging, it requires the packaging material to have excellent barrier properties to prevent the drug from being affected by moisture, oxidation or other external factors and becoming ineffective.

PVDC can be coated on PVC film to obtain high moisture and oxygen resistance, depending on the coating weight (40g/60g/90g/120g/180g). PVDC coated blister film is the most common and popular barrier film used for pharmaceutical blister packaging. PVDC coating is also the most economical way to add waterproof and oxygen resistance to PVC film. PVDC blister film has 2-layer or 3-layer specifications, called PVC/PVDC or PVC/PE/PVDC.

Advantages:

1. High barrier property: The PVDC layer can effectively prevent water vapor and oxygen from penetrating, and is particularly suitable for drugs that are sensitive to humidity and oxygen.

2. High transparency: Ensure good product visibility, making it easy for consumers to view the contents of the package.

3. Good heat sealing: Good heat sealing with aluminum foil (PTP) ensures sealing effect and prevents contamination and leakage.

4. High mechanical strength: Suitable for high-speed automated packaging production lines, not easy to break or deform.

5. Strong chemical resistance: Suitable for a variety of drugs, including tablets, capsules, soft capsules, etc.

6. Multiple specifications available: Choose different thicknesses and PVDC coating weights (40g, 60g, 90g, etc.) according to drug protection needs.

Specifications:

| Product name | High barrier PVDC coated film PVC |

| Application | Medical packaging |

| PVC thickness | 0.25mm, 0.35mm or customized |

| PVDC coating | 40gsm, 60gsm, 90gsm, 120gsm, 120gsm |

| Width | Slitting: 70-300 mm; Big roll: 500-1600 mm |

| Inner core diameter | 76 mm |

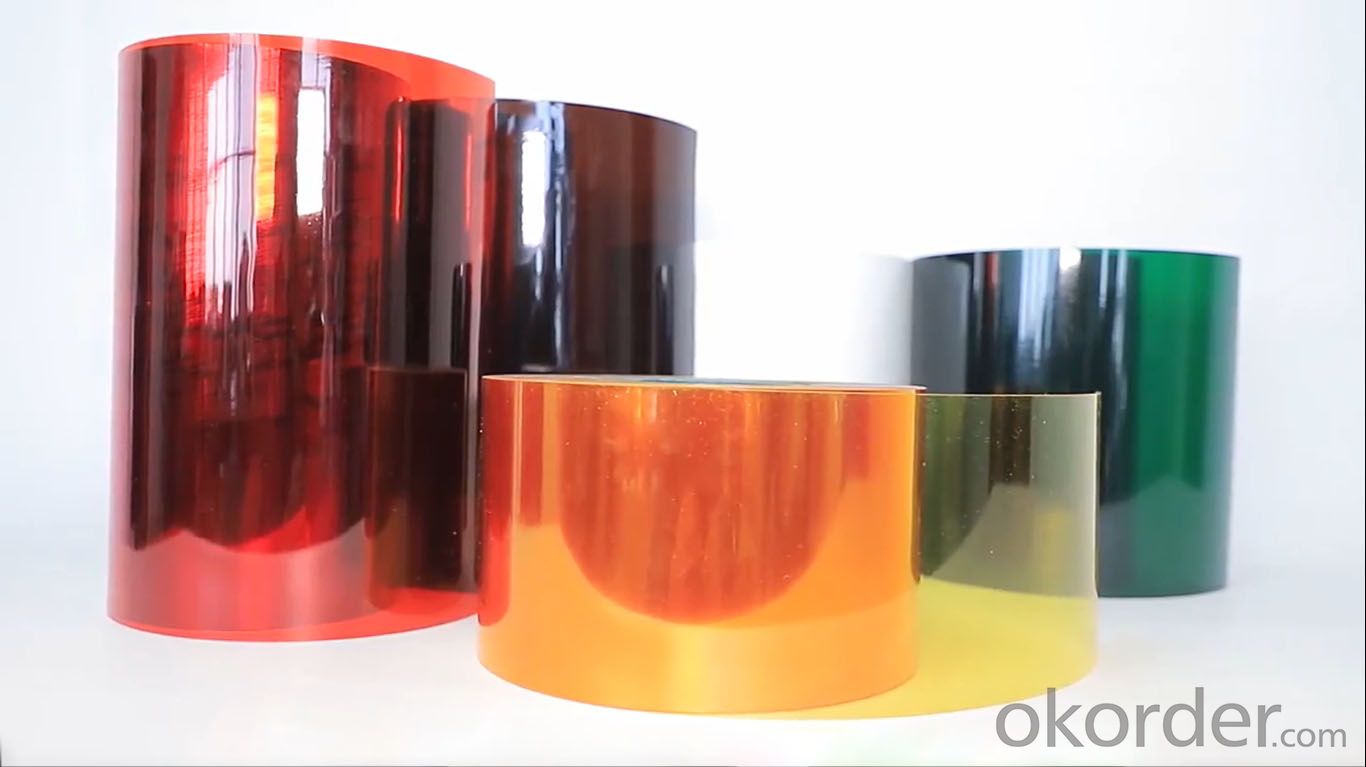

| Color | transparent, white, red, etc. |

| Surface | bright, clean, shiny |

| Delivery time | 7-10 days |

| Packaging | in pallets, cartons, etc. |

| Advantages | 1. High transparency, bright surface brightness. 2. Smooth surface, uniform thickness. 3. Few water marks, few crystal points. 4. Odorless and non-toxic. 5. Cold resistant. 6. Easy to thermoform, print and fold. 7. Transparent in various colors. |

Physical properties

| Appearance | flat, uniform, clean. No holes. No foreign matter. No odor. No impurities. No adhesion. |

| Water vapor permeability | ≤0.5g/(m2.24h) |

| Oxygen permeability | ≤0.5cm3/(m2.24h.0.1Mpa) |

| Sealing strength | ≥7.5N/15MM |

Application areas:

Pharmaceutical packaging: such as blister packs for capsules, tablets, pills, etc.

Health care product packaging: used for vitamins, soft capsules and other products.

Food packaging: Some are used for packaging of moisture-sensitive foods, such as candy or dehydrated foods.

Company information:

Packaging delivery:

Packaging size: 25.00 cm * 25.00 cm * 25.00 cm

Package gross weight: 25.000 kg

Faq:

Q1: How to ensure the quality?

A1: Factory test certification is provided with shipment, third-party inspection is available

Q2. What are the main products of your company?

A2: Our main products are aluminum, aluminum plate, aluminum foil, aluminum strip, patterned plate, automotive plate, marine grade aluminum plate, household foil, hydrophilic aluminum foil, bottle cap material, PVC hard sheet, pvc/pvdc composite hard sheet, aluminum-plastic blister packaging, etc.

Q3: Where is your factory located?

A3: Our company's processing center is located in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Q4: What are the advantages of your company?

A4: We have many professionals, technicians, more competitive prices and best after-sales service than other companies.

- Q: What are the considerations for storage and transportation of medical plastic products?

- The considerations for storage and transportation of medical plastic products include maintaining proper temperature and humidity conditions, ensuring product integrity and sterility, preventing contamination, using appropriate packaging materials, following regulatory requirements, and implementing quality control measures. Additionally, careful handling, labeling, and tracking of the products are essential to maintain their safety and effectiveness throughout the supply chain.

- Q: Can medical plastics be customized for specific applications?

- Yes, medical plastics can be customized for specific applications. Medical plastics are versatile materials that can be tailored to meet the specific requirements and needs of various medical applications. They can be modified in terms of composition, properties, and performance to ensure compatibility with specific medical devices, implants, packaging, or other healthcare-related products. Customization allows for the development of safe, durable, and efficient solutions that meet the unique demands of various medical applications.

- Q: What are the different grades of medical plastic?

- Medical plastics can be classified into several grades based on their specific properties and applications. Some common grades include implantable medical plastics, which are biocompatible and suitable for long-term use inside the human body; medical device plastics, which are used in the manufacturing of various medical equipment and instruments; packaging and tubing plastics, which are used for sterile packaging and fluid transfer; and pharmaceutical grade plastics, which are used in the production of drug containers and packaging materials. Each grade has its own set of requirements and regulations to ensure safety and effectiveness in medical applications.

- Q: How is medical plastic regulated and tested for compliance?

- Medical plastic is regulated and tested for compliance through rigorous processes and regulations. Regulatory bodies such as the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in Europe, and similar agencies worldwide establish guidelines and standards for medical plastic materials. These regulations outline the requirements for safety, quality, and performance of medical plastics. To ensure compliance, medical plastics undergo extensive testing. This includes biocompatibility testing to assess the material's interactions with living tissues, such as cytotoxicity, sensitization, and irritation tests. Other tests may include chemical analysis, mechanical testing, and sterilization validation. Manufacturers are responsible for conducting these tests and documenting their results to demonstrate compliance with regulatory requirements. Additionally, third-party testing laboratories may be involved in verifying the safety and efficacy of medical plastics. Overall, the regulation and testing of medical plastic are critical in ensuring the highest standards of safety and performance for medical devices and packaging materials used in healthcare settings.

- Q: Plastic gloves are several kinds of medical instruments?

- The gloves and the protective gloves belong to a kind of medical instruments, and the asepsis medical gloves belong to the two kind of medical instruments.

- Q: What are the challenges in sterilizing medical plastic?

- One of the main challenges in sterilizing medical plastic is ensuring that the sterilization process effectively kills all microorganisms without damaging or degrading the plastic material. Different sterilization methods, such as steam, ethylene oxide gas, gamma radiation, or hydrogen peroxide plasma, each have their own limitations and can pose risks to the plastic's structural integrity or patient safety if not properly controlled. Additionally, certain plastic materials may be more difficult to sterilize due to their composition, shape, or surface characteristics, requiring specialized techniques or packaging to achieve adequate sterilization. Overall, the challenge lies in striking a balance between achieving sterilization efficacy while preserving the functionality and safety of the medical plastic.

- Q: Can medical plastics be sterilized?

- Yes, medical plastics can be sterilized through various methods such as steam sterilization, ethylene oxide gas sterilization, gamma radiation, or hydrogen peroxide plasma sterilization. These methods effectively eliminate any microorganisms present on the plastic surfaces, making them safe for use in medical settings.

- Q: How do medical plastics contribute to the field of dentistry?

- Medical plastics play a crucial role in dentistry as they are widely used in the fabrication of various dental devices and materials. These plastics are utilized in the production of dental implants, dentures, orthodontic brackets, and clear aligners, among others. They offer several benefits such as biocompatibility, durability, and aesthetics, making them ideal for dental applications. Additionally, medical plastics provide cost-effective and time-efficient solutions, enabling dentists to provide patients with high-quality dental care.

- Q: Are there any regulations for the disposal of medical plastic waste?

- Yes, there are regulations for the disposal of medical plastic waste. These regulations vary by country and region, but generally, medical plastic waste must be properly segregated, packaged, and disposed of in accordance with local guidelines. This ensures the safe handling and disposal of potentially hazardous materials, minimizing the environmental impact and potential health risks associated with medical plastic waste.

- Q: What are the potential reproductive effects of medical plastics?

- The potential reproductive effects of medical plastics can vary depending on the specific type of plastic and the exposure level. Some studies suggest that certain chemicals found in medical plastics, such as phthalates, may have endocrine-disrupting properties and could potentially affect fertility, fetal development, and hormone balance. However, more research is needed to fully understand the extent of these effects and to develop appropriate regulations and guidelines to minimize any potential risks.

Send your message to us

Hot selling medical grade 0.2/0.25/0.3mm transparent PVC / PVDC film for pill blister packaging

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products