Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portable Floss roll clean environmentally friendly floss roll for house

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Brand OEM/Ok Floss

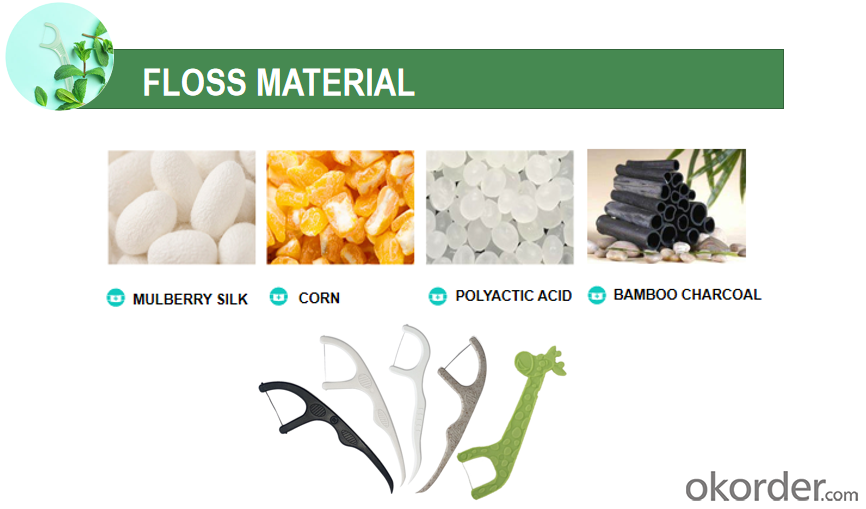

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

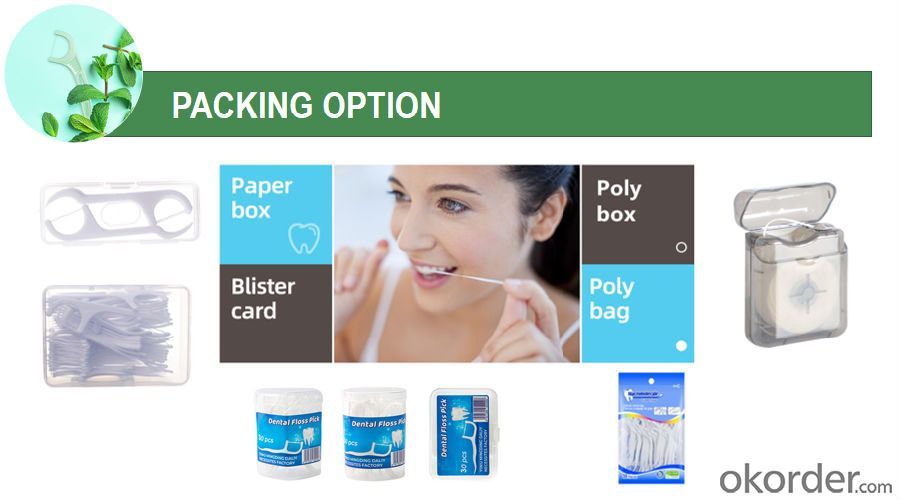

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What is the plastic model?

- Thermoplastic plastics can be divided into general plastics, general engineering plastics, high-performance engineering plastics and other three categories.General plastics often refer to: ABS, PE, PVC, PMMA, PS, PP1. propylene butadiene - diene (ABS) copolymerAdvantage1, hard, easy to pledge2, easy to dye3, nonflammable4, shock resistance5, good surface

- Q: Can Fuji medical dry imager 3500 print thermal sensitive film?

- High efficiency: print speed is several times more than the traditional camera, not afraid of light, be afraid of heat, to avoid the two film the fog exposure machine, can save time for more than 30 years

- Q: Can a plastic pot filled with a dialysis solution be washed and loaded? Why is there any liquid left per pot?

- No, after all, those used are medical waste. Moreover, the medical grade is not the same as the food grade, and its original design does not consider the inclusion of food and alcohol

- Q: What are the considerations for selecting medical plastic for patient comfort?

- When selecting medical plastic for patient comfort, several key considerations need to be taken into account. Firstly, it is crucial to choose a material that is hypoallergenic to minimize the risk of allergic reactions or irritations. Additionally, the plastic should be soft and flexible to ensure it conforms comfortably to the patient's body contours, without causing discomfort or pressure points. The material should also have a smooth surface to prevent chafing or abrasions. Lastly, it is important to consider the breathability of the plastic to allow air circulation and prevent excessive sweating or moisture build-up, which could lead to skin irritations or infections.

- Q: How do medical plastics help in reducing the weight of medical devices?

- Medical plastics help in reducing the weight of medical devices through their lightweight and durable characteristics. These plastics are significantly lighter than traditional materials such as metal, which allows for easier handling and transportation of medical devices. Additionally, medical plastics can be molded into complex shapes, enabling the design of lightweight and ergonomic devices that are comfortable for patients and healthcare professionals to use.

- Q: Are there any potential allergic reactions to medical plastics?

- Yes, there is a possibility of allergic reactions to medical plastics. Some individuals may develop hypersensitivity or allergic reactions to certain components or additives used in medical plastics, such as latex or various chemicals. It is crucial for healthcare professionals to be aware of a patient's medical history and any known allergies to prevent adverse reactions.

- Q: How do medical plastics impact the design of medical equipment?

- Medical plastics have a significant impact on the design of medical equipment as they offer numerous advantages such as being lightweight, durable, and easily sterilizable. These properties enable the creation of more portable and ergonomic devices, facilitating better patient care and comfort. Additionally, medical plastics allow for the integration of complex components, enhancing functionality and improving overall performance.

- Q: How does medical plastic help in reducing the risk of medical waste generation?

- Medical plastic helps in reducing the risk of medical waste generation by providing a safe and hygienic material for various medical devices and equipment. It is designed to be disposable, preventing the need for reusing certain items that could potentially lead to contamination and the spread of infections. Additionally, medical plastic is lightweight and flexible, allowing for efficient packaging and transportation of medical supplies, thereby reducing the overall amount of waste generated in the healthcare industry.

- Q: What are the benefits of using medical plastics in healthcare?

- There are several benefits of using medical plastics in healthcare. Firstly, medical plastics are lightweight and durable, making them ideal for manufacturing medical devices and equipment. They are also resistant to chemicals and can be easily sterilized, ensuring a high level of hygiene in healthcare settings. Additionally, medical plastics can be molded into various shapes and sizes, allowing for customization and improved patient comfort. Furthermore, these plastics have low friction properties, reducing the risk of infections and improving patient outcomes. Overall, the use of medical plastics in healthcare offers numerous advantages, including improved safety, functionality, and efficiency in medical settings.

- Q: What are the considerations for ensuring the biodegradability of medical plastic materials?

- Some considerations for ensuring the biodegradability of medical plastic materials include selecting biodegradable polymers or additives, optimizing the degradation rate to match the intended lifespan of the product, assessing the impact of degradation byproducts on human health and the environment, conducting rigorous testing for biodegradability in relevant conditions, and ensuring appropriate disposal methods to facilitate biodegradation.

Send your message to us

Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords