Polyethylene Long Lasting Insecticide Treated Mosquito Nets for Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

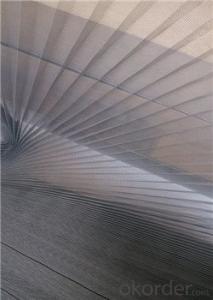

Introduction of Mosquito Net

This long lasting mosquito bed net is hooked on the ceiling and tucked under your mattress for overnight protection from bites. The deltamethrin treatment provides 4-5 years of protection, unlike permathrin which only lasts about 1 year. Insecticide treated mosquito nets, if used properly, are one of the best ways to prevent mosquitoes from biting and infecting individuals with malaria and other mosquito-borne diseases.

Details of Mosquito Net :

Lasts 4-5 years

Suitable for beds of all dimensions

For one or two people

Attaches to ceiling

Can be suspended from a ceiling

Pre-treated as per World Health Organization guidelines

Services of Mosquito Net :

Pre-sale services:

1.Various kinds of mosquito nets to choose from.

2.Any customized products can be satisfied according to your requirements.

3.Professional technicians engaged in each procedures.

Services during the sale:

1.Pre-checking and safeguarding products before delivery.

2.Providing solutions for any unexpected conditions involved.

After-sale services:

1.Assist customers on how to hang the exact mosquito nets.

2.Provided with instructions or vidoes of certain mosquito nets foldings.

3.24-hour Services.Contact us for any questions, we'd be gladly to follow.

Packaging & Delivery of Mosquito Net :

| Packaging Detail: | Individually packed into branded plastic bag,100 units per bale. |

| Delivery Detail: | 2 weeks after confirm order and payment |

FAQ of Mosquito Net:

1.Sample

We'd be gladly to send you the sample for free, but you need to pay for transport cost, and we will turn back this amount of money to you after orders issued.

2. MOQ

Our minimum order quantity for mosquito net is 1,000 pieces, and 500 kilograms for fleece fabric and mosquito net fabric.

3.Color, Size

Any color and any size is available as long as it's connected with mosquito nets.

- Q: How does medical plastic help in medical packaging?

- Medical plastic helps in medical packaging by providing a safe and sterile environment for medical devices, instruments, and medications. It offers excellent barrier properties, preventing the entry of contaminants such as bacteria and moisture, which can compromise the integrity of the product. Medical plastics also provide protection against UV light and ensure product stability during transportation and storage. Additionally, they allow for easy identification and labeling of medical products, ensuring efficient inventory management and traceability.

- Q: Can medical plastics be used in neurological applications?

- Yes, medical plastics can be used in neurological applications. They are often used in the development of various medical devices and implants for neurological surgeries and treatments. These plastics offer advantages such as biocompatibility, flexibility, and durability, making them suitable for applications like neurostimulation devices, cranial plates, and spinal implants.

- Q: How does medical plastic contribute to the development of personalized prosthetics?

- Medical plastic plays a crucial role in the development of personalized prosthetics by providing a versatile and customizable material for creating prosthetic components. Its unique properties, such as durability, flexibility, and biocompatibility, allow for the creation of prosthetics that are tailored to an individual's specific needs and preferences. Medical plastic can be easily molded and shaped into intricate designs, facilitating the production of prosthetic limbs that closely mimic the natural movements and appearance of real limbs. Additionally, the lightweight nature of medical plastic makes the prosthetics more comfortable to wear, enhancing mobility and overall quality of life for individuals in need of prosthetic solutions.

- Q: How do medical plastics help in reducing the risk of instrument breakage during surgeries?

- Medical plastics help in reducing the risk of instrument breakage during surgeries by offering properties such as high strength, durability, and flexibility. These materials are used to manufacture surgical instruments and equipment, providing a lightweight but sturdy alternative to traditional materials like metal. Medical plastics are less brittle and more resistant to impact, reducing the chances of breakage or damage during surgical procedures. Additionally, their smooth and non-reactive surfaces prevent corrosion and facilitate easy sterilization, ensuring the safety of patients and healthcare professionals.

- Q: What are the mechanical properties of medical plastic?

- The mechanical properties of medical plastic include factors such as strength, stiffness, impact resistance, and flexibility. These properties are crucial in ensuring that medical devices made from plastic can withstand various stresses and strains, while also maintaining their shape and integrity. Additionally, medical plastics often exhibit properties such as biocompatibility, sterilizability, and chemical resistance, which are important for their usage in healthcare settings.

- Q: How can you remove the moss from the plastic bucket?

- Lichen formation is mainly due to the following four points:1, different water quality, lichen production in water quality is very related.2, and the quality of plastic barrels have a great relationship, it is recommended to buy quality guaranteed food grade plastic bucket.3, avoid plastic barrels are exposed to sunlight, because the sun's ultraviolet rays will produce moss.3, try not to let the water in the plastic bucket in the residence for too long, forming stagnant water, but also easy to produce moss.You can prevent the formation of lichen because of the formation of moss.

- Q: What are the challenges in sterilizing medical plastic?

- Sterilizing medical plastic poses several challenges due to its complex composition and sensitive nature. The primary challenge is selecting the appropriate sterilization method that effectively kills all microorganisms without compromising the plastic's integrity and functionality. Some sterilization techniques, such as high temperatures or strong chemicals, can cause plastic degradation, leading to loss of strength, dimensional changes, or release of toxic substances. Additionally, ensuring consistent and uniform sterilization throughout the plastic material can be difficult, especially in complex and intricate designs. Overall, striking a balance between effective sterilization and preserving the plastic's properties remains a significant challenge in the medical field.

- Q: How to remove the plastic flavor of the new thermos cup?

- 1, for the first time, to ensure cleaning, 1~2 drip vinegar can be dropped into warm water diluted, pour into the cup, in the open cup cover for 30 minutes, and then wash with a soft cloth.2, cup and back body separation, open, in ventilated position, placed for 1-2 days, basically can go to taste. (the new ones are best cleaned with detergent).3, buy back the cup, wash with detergent, pour hot water, cover, put to the water temperature, cooling, pour water, and then lay aside for a period of time, basically can dispel the smell.

- Q: How does medical plastic contribute to the development of prosthetics and orthotics?

- Medical plastic plays a crucial role in the development of prosthetics and orthotics by providing versatile and durable materials that can be molded into various shapes and sizes. It allows for the creation of lightweight and comfortable prosthetic limbs and orthotic devices, enhancing the mobility and functionality of individuals with disabilities. Additionally, medical plastic offers hypoallergenic properties, easy sterilization, and resistance to wear and tear, ensuring long-term usage of prosthetics and orthotics.

- Q: What are the cost considerations for medical plastic products?

- The cost considerations for medical plastic products include the cost of raw materials, manufacturing processes, quality control measures, regulatory compliance, and packaging. Additionally, factors such as product design complexity, volume of production, and market competition can impact the overall cost of medical plastic products.

Send your message to us

Polyethylene Long Lasting Insecticide Treated Mosquito Nets for Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords