Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Children's Safe Flavoring Dental Floss Pick

| Brand: | OEM/Ok Floss |

| Floss material: | UHMWPE,Charcal as customized |

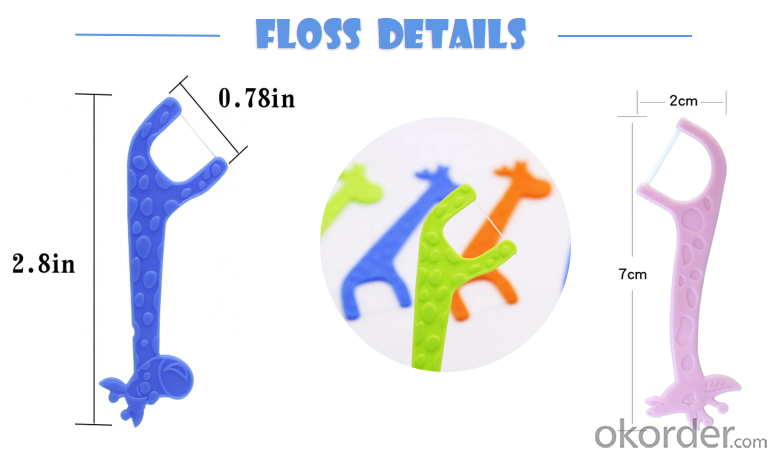

| Size: | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax: | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor: | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color: | Floss original color |

| Floss original color: | Individual bulk PP bag/individual paper box/as customized |

| Applications: | Family,Hotel,Travel,Supermarket |

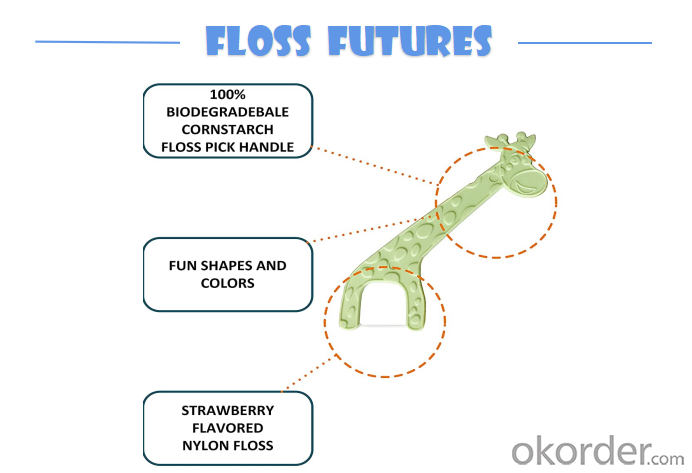

| Shape: | Bear,Giraffe,Cola |

| Lead time: | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE

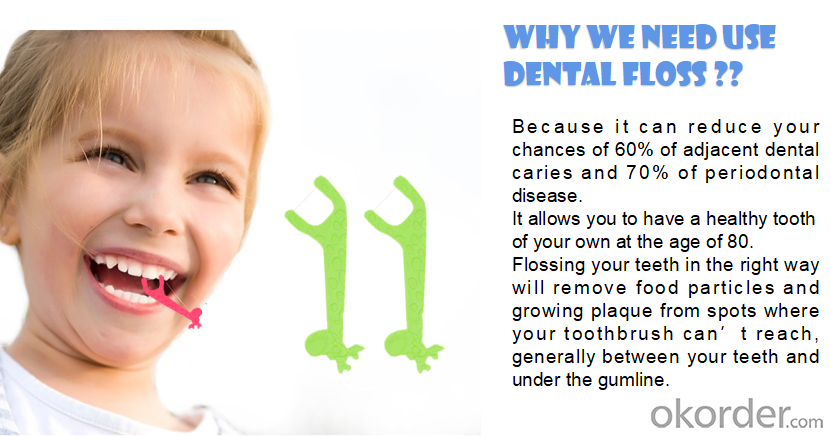

REDUCE ADJACENT DENTAL CARIES

DENTAL FLOSS FOR KIDS

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

DENTAL FLOSS DETAILS & SIZE

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: What kind of plastic is used in medical instruments? Can also be sterilized at high temperature

- Ethylene oxide is difficult to transport, so you can see the supply locally. If you do not have the ability to disinfect, you can also find medical equipment company oem.

- Q: How do medical plastics help in reducing the weight of medical devices?

- Medical plastics help in reducing the weight of medical devices through their lightweight and durable characteristics. These plastics are significantly lighter than traditional materials such as metal, which allows for easier handling and transportation of medical devices. Additionally, medical plastics can be molded into complex shapes, enabling the design of lightweight and ergonomic devices that are comfortable for patients and healthcare professionals to use.

- Q: How do medical plastics contribute to cost savings in healthcare?

- Medical plastics contribute to cost savings in healthcare in several ways. Firstly, they are lightweight and durable, making them cost-effective alternatives to traditional materials. This reduces transportation and handling costs. Secondly, medical plastics are often single-use, preventing the spread of infections and eliminating the need for expensive sterilization processes. Additionally, they are compatible with various sterilization methods, allowing for efficient and cost-effective cleaning. Moreover, medical plastics enable the development of advanced medical devices and equipment that improve patient outcomes and reduce the need for costly procedures. Overall, the use of medical plastics in healthcare helps streamline processes, reduce expenses, and ultimately contribute to cost savings.

- Q: How is medical plastic used in ophthalmic devices?

- Medical plastic is commonly used in ophthalmic devices due to its versatility and safety. It is used to manufacture various components of these devices, such as intraocular lenses, contact lenses, and surgical instruments. The plastic used in ophthalmic devices is biocompatible, lightweight, and durable, making it suitable for long-term use in the eye. Additionally, the transparent nature of medical plastic allows for excellent visual clarity, enabling optimal vision correction and treatment of eye conditions.

- Q: What are the considerations for using medical plastic in wearable infusion pumps?

- When considering the use of medical plastic in wearable infusion pumps, several key factors need to be taken into account. First and foremost, the chosen plastic material must be biocompatible, meaning it does not cause any adverse reactions or harm to the patient's body when in contact with their skin or bodily fluids. Additionally, the plastic should possess good chemical resistance to ensure compatibility with various medications and fluids being administered. The material's mechanical properties, such as flexibility and durability, are crucial for the wearable nature of the device, ensuring it can withstand daily use and movement without compromising its functionality. Lastly, considerations regarding sterilization methods and the ability to maintain a sterile environment are also important factors to ensure the safety and effectiveness of the wearable infusion pump.

- Q: Can medical plastics be implanted in the body?

- Yes, medical plastics can be implanted in the body. They are commonly used in various medical devices and implants, such as joint replacements, pacemakers, and stents, due to their biocompatibility and durability.

- Q: Can medical plastics be used for pain management or anesthesia?

- Yes, medical plastics can be used for pain management or anesthesia. Medical plastics such as catheters, syringes, and drug delivery devices play a crucial role in administering pain medications and anesthetics to patients. These plastics are designed to be safe, sterile, and compatible with various drugs, allowing healthcare professionals to effectively manage pain and provide anesthesia during medical procedures.

- Q: How can you remove the moss from the plastic bucket?

- Plastic buckets for various reasons, it is easy to form moss in the interior, unsanitary, it is difficult to clean up. The following three methods can effectively remove the moss in the plastic bucket:1, if only a simple cleaning, there is no special requirements, then use hot water soak for a while, rinse more than a few times can be removed.2, if you need to dress up food (generally not recommended plastic barrel food), use hot water to clear moss, and then thoroughly disinfected with medical alcohol.3, you can use a proper amount of industrial banana water to clear moss, and other banana water, volatile, after washing with hot water, alcohol disinfection, placed for a period of time can be.

- Q: Barrier properties of plastic packaging, including separation of what?

- Oral solid and liquid medicinal plastic bottles are a type of package material. Without cleaning and sterilization, it can be used in drug packaging, therefore, the microbial limit is higher, the production environment and production process should comply with the requirements of the relevant laws and regulations.

- Q: How does medical plastic contribute to the development of biomaterials?

- Medical plastic plays a crucial role in the development of biomaterials by providing a versatile and customizable platform for creating various medical devices and implants. Its unique properties, such as biocompatibility, durability, and flexibility, allow for the fabrication of biomaterials that can mimic natural tissues and organs. Medical plastic enables the production of implants, prosthetics, and medical devices that are safe, reliable, and capable of integrating seamlessly with the human body, thereby advancing the field of biomaterials and improving patient outcomes.

Send your message to us

Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords