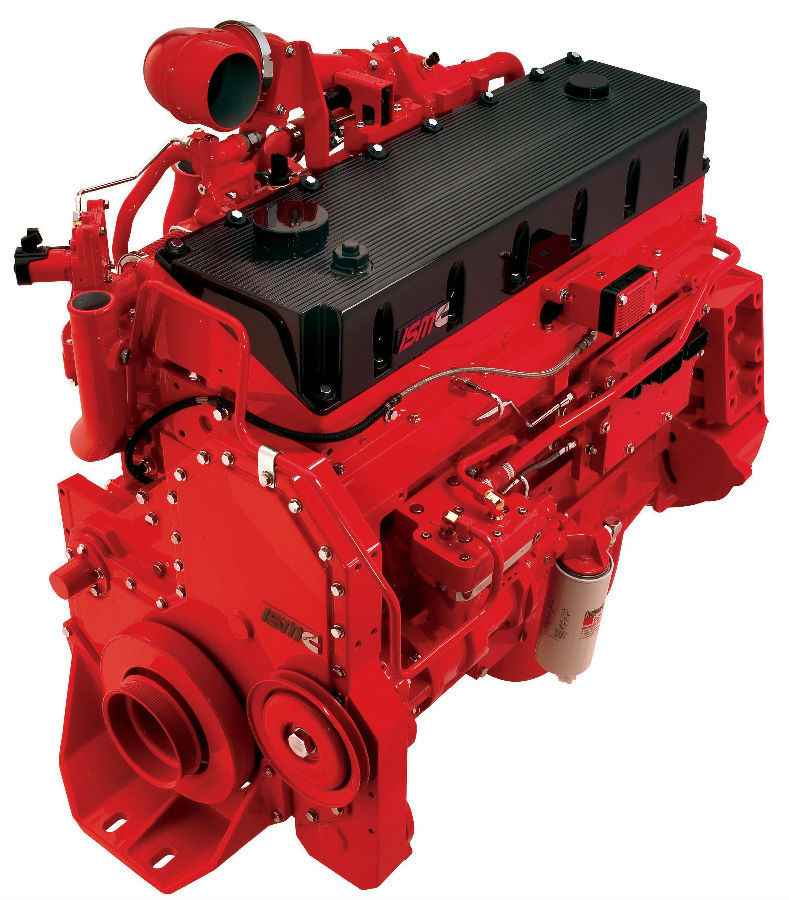

Cummins Engine Diesel Generator with Light Tower ATS Trailer) 50kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low-noise 50kva Cummins diesel generator 50hz or 60hz

Briefe performance of silent diesel generator set

1)High quality, steady and reliable performance

2)Blow 71dB at 7 meter

3) Perfect Maneuverability

4) Wide Application

Engine:

Manufacturer | CUMMINS | |

Model | 4BTA3.9-G2 | |

Cylinder and cycle type | 4 cylinders in line, 4 strokes | |

Aspiration and cooling | Turbocharged and after cooled | |

Displacement | 3.9 L | |

Bore×Stroke | 102×120 mm | |

Compression ratio | 16.5:1 | |

Rated speed | 1500 rpm | |

Governor | Electronic | |

Oil capacity | 10.9 L | |

Prime power | 50kW | |

Standby power | 55kW | |

Fuel consumption | 12.4L/H (100% Load) | 9.3L/H (75% Load) |

Coolant capacity | 7.2 L | |

Start system | DC 24V | |

Alternator:

Manufacturer | STAMFORD |

Model | UCI224D |

Type | Single bearing,4-pole,AC brushless and self-exciting |

Frequency | 50 Hz |

Power Factor | cosΦ=0.8 |

Phase | 3 |

Voltage | 400/230 V |

Capacity | 40kW/50kVA |

Insulation class | H |

Protection class | IP23 |

Elevation | ≤1000m |

Control system:

Optional: DSE or Smartgen

Manufacturer: SNARTGEN

MODEL: HGM6120KC

HGM6120KC Control System is mainly used in generating supervising and control of land type diesel generator set and the switching between diesel generator set and city electricity supply. It is combined with digitalization, intelligence and network and capable of generator start and stop, generator data supervising and testing, protection alarm, city electricity supply quality supervising and starting generator automatically when power failure happens or city electricity supply is beside the set point.

Control system: Light tower/ Trailer generator set:

- Q: where are ac motors used at today?

- Everywhere that the voltage supply is AC - and that's pretty much everywhere there's an electrical outlet.

- Q: Is the stepping motor an alternating current motor or a direct current motor?

- The stepping motor is an open loop control element which transforms the electric pulse signal into angular displacement or linear displacement. In the case of non overloaded, the motor speed and stop position depends only on the pulse frequency and pulse number, regardless of load changes, when the stepper driver receives a pulse signal, it drives stepper motor to set the direction of rotation of a fixed angle, called "step", it is the rotation of the fixed point of the operation step by step. Number of pulses can be controlled by controlling the angular displacement, so as to achieve the purpose of accurate positioning; at the same time by controlling the pulse frequency to control the motor rotation speed and acceleration, so as to achieve the purpose of speed.

- Q: My dad owns this car and the AC recently went out and he does not have accessibility to information regarding how to replace the blower motor. Has anyone done this, or do you have access to detailed instructions from Chilton's, etc.? I tried to look online, but I came up empty-handed. My dad used to own an auto repair shop, so do not worry about your response being too detailed or technical. Any assistance would be greatly appreciated. Thank you in advance.

- discover the blower motor and unplug the electric connection. clean any rust from the area and reconnect. that could shelter it. I purely did that with my daughter's chevrolet final month here in Michigan. If it makes an unusual noise like a screech, that usually shows the around plastic piece that the motor turns is wiped out and desires changing. That expenses approximately $20.

- Q: Why is an AC motor more popular than a direct current motor? System description, thank you.

- The reason of AC motor is common and convenient power supply: power generator and transformer, transmission and distribution in the form of communication, AC power supply, the utility grid can be directly used for AC motor is simple and convenient; DC motor to be alternating to direct before use, trouble.2, AC motor especially the induction motor, has the advantages of simple structure, easy manufacture, convenient installation, reliable use, low cost, high efficiency; and the DC motor is complicated in structure, manufacture and installation of trouble, use is not reliable, high cost, low efficiency.

- Q: i need the starting torque and speed (rpm) of the following motors:Shaded PoleReluctance StartSplit Phase (Standard)Split Phase (Capacitor Start)Split Phase (Permanent Split Capacitor)Split Phase (Two Value Capacitor)Universal / SeriesRepulsion (Repulsion Start)Repulsion (Repulsion-Induction)Synchronous (Reluctance)Synchronous (Subsynchronous Reluctance)Synchronous (Hysteresis)Eddy CurrentInduction (Squirrel-cage)Induction (Wound-rotor)Commutator (Schrage)Commutator (Fynn-Weichsel)3? Synchronous (Permanent Magnet)3? Synchronous (Synchronous Reluctance)3? Synchronous (Hysteresis)3? Synchronous (Synchronous Induction)Stepper (Permanent Magnet)Stepper (Variable Reluctance)Switched Reluctance MotorCapacitor MotorRepulsion

- for more details go to google

- Q: 3-Phase, AC Motor ElectricWhen 2 or more wires are twisted together, is a wire nut placed over the exposed wires? How are 2 separate wires properly connected?

- Its common practice in the US to use wire nuts in motor terminal boxes. Its very unfortunate that they don't contain suitable terminals as the case in European motors, in fact wire nuts are not considered appropriate connections even in domestic applications in Europe. The problem with wire nuts, especially in motors that vibrate, is they offer little mechanical strength. My advise would be to find screw type connectors. They are often refered to as Euro connectors in companies that sell them such as Allied or Grainger. Many parts of East Asia also have motors without terminals and here they use crimp terminals and bolt them together followed by a procedure of taping. You may find this in larger motors in the US

- Q: I'm not going to lie and say I know a whole lot about the physical side of electronics, so I'll just straight out and ask if I could run a stepper motor I stripped out of a scanner on a series of D batteries (adding up to 12v, the motors operating voltage)

- they run on DC, and yes, you can run one on batteries. If you're not fussy, DC supplies are all around. You have one in the scanner. .

- Q: I was told the bearings in the old motor were bad thats why it was seizing up in the first place that why it was doing it in the first place but its still doing it.... Please help

- Yes it could be a bad motor, even fresh out of the carton.... BUT also check your wiring-connected properly, is fan spinning freely by hand when power is off, are all wires and connections tight and intact, and how is the capacitor. Is there a seperate capacitor for the fan? Also, saw this once-are any of the fan blades hitting the inside of the consenser coils. Loook for gouges on INSIDE of the condenser coils. Good Luck

- Q: if i change voltage will the rpm of motor will be affected

- if it is dc motor speed is proportional to voltage. for induction motor without load it will not depend on voltage much but only frequency

- Q: why do elec motors ang geysers have high starting current?

- ang? motors pumping water have to overcome inertia and flow friction in pipes.

Send your message to us

Cummins Engine Diesel Generator with Light Tower ATS Trailer) 50kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords