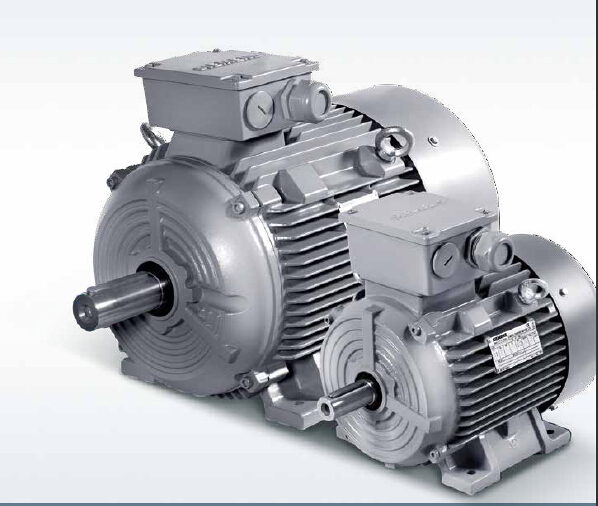

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: it has 3 wires coming out, what are they for?

- Two are for the AC power and one is for the ground, Im guessing. If they are very light guage wire it could be for some sort of remote, but since its old who knows. Any pics?

- Q: Or does it only work with a DC motor?

- You can get a transformer to work on DC provided that the DC is varying (or pulsing) . Consider how the coil in a car steps up the 12VDC of a battery to thousands of volts for the spark plugs by pulsing DC through the primary of the coil.. Because the DC motor has a commutator its DC output will resemble that of a full wave rectifier. The variations in the DC will be passed to the secondary of the transformer. Despite feeding a transformer input with pulsating DC, the output of the transformer will be AC so you will need a full or half wave rectifier and it would also help to place a capacitor across the rectifier output to smooth the DC.. Also the power (E * I) input is the same as the output, meaning that if you take 1 V @ 10A (10W) on the input and step it up to 10V at the output you will still have 10W of power at the output which means that the current will drop to 1A. 1V @ 10A in stepped up to 10V @ 1A. Finally as current is supplied from your tiny generator (motor) that current flow will create a counter electromotive force. Simply, as you supply current from your generator it will get harder to turn the generator. Your generator might be turning in a slight breeze now only because there is zero load on it. Once you connect a load (transformer / led etc) you will find that it will take more effort (breeze) to turn the generator. Despite all of the above the step up conversion of the fullwave DC won't be very efficient . Instead of a DC hobby motor as your generator try using a Servo / stepper motor instead. There is no commutator in these types of motors so you should be able to get an AC sine wave output which will be more efficient in stepping up with a transformer.

- Q: Is it possible to increase an HP of motor by doing some changes in winding ?

- Not practically. The horsepower rating has to do with the mechanical torque that the motor can deliver to its shaft. Typically, the limitation is the temperature rise in the windings. To increase the horsepower output, you would need to change the windings in a way that would allow more current to flow without causing the motor temperature to exceed the maximum temperature of the insulation of the windings. That means rewinding the motor using insulation material that has higher temperature withstand capabilities. Physically, this may result in different physical dimensions and may not be possible. In any case, economic practicality is also probably an issue - it may cost more to have a specialty shop rewind the motor that it would cost to buy a replacement..

- Q: The coils in a motor are being magnetized when we supply AC current to it and thus the motor runs.What is the magnetic power produced in the coils in terms of quot;Teslasquot; when the motor is being run in full speed?

- The magnetic field strength does not change for AC motor,because power is applies to its field coils (do not mix it up with AC-DC series motor,field strength changes follow the load). To measure the AC magnestic field strength is quite difficult because the field polarization keep on changing according to the frequency. A hard way to find out is counting how turns of coil and the size of steel area,then calculate it.

- Q: If i spin a ac electric motor backwards will it produce electricity?

- No, it won't.

- Q: related to electric goodshow much is thge consuption of 1/4 hp motor

- Single phase (what comes out of your wall outlet) as opposed to three phase motors that are usually used for motors 1 Hp and up in industrial applications. 3 phase is more efficient on large motors.

- Q: If my old AC motor rpm was 850, what damage will a 1050 rpm motor cause?

- Context? It depends on what it's driving. But we don't know that, do we? Tell us more and we can tell you more.

- Q: like the Q says ac and heat quit working on my 03 durango does nothing at all on high works on all other settings.

- Best of luck: If you don't feel comfortable installing it get a mechanic to install it or diagnose the problem.

- Q: What is the neutral point of an alternating current motor? How to determine whether the neutral point leads to?

- The AC motor only meets the three-phase fire line, the three-phase is balanced, the neutral point does not connect the zero line, also does not have the ground.

- Q: What advantage does an AC motor have over a DC motor?

- It depends on your application. Fans, appliances, and clocks would benefit from a/c because in these cases a/c motors are less expensive and use the a/c frequency to regulate rotational speed. If your application involves speed and or position control (tredmill, hard drive, electric vehicle) then the better motor would be DC.

Send your message to us

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords