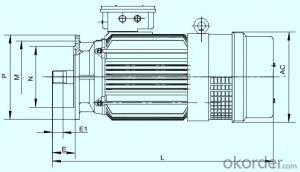

YTPEZ (1P54) Three一Phase Asynchronous Motor for Travel Mechanism of Tower Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview

The motor is a variable-

mechanisms in very harsh

frequency

working

,three-phase asynchronous motor exclusively designed for tower cranes and other similar travel mechanisms. It is applied to the travel

conditions such as construction site or open pit quarry

Features

Introduction of a spline drive shaft, with excellent mechanical bearing capacity;

Variable-frequency speed regulation in a broad range with high efficiency, small starting current, big starting torque and strong overload capability;

Duc to compact structure, small size, lightweight, high reliability, it can be quickly braked and accurately located, suitable for frequent starling and braking;

Introduction of a new brake (national utility model patent. Patent No. ZL201120188173.2, ZL2011201881643). It can buffer the startup to mitigate the impact on the

tower crane. In addition, the motor has very high security and reliability, and can reduce the maintenance time, and cut down the maintenance cost;

A thermal protection component is buried into Lhe stator winding, so the motor operation is more secure and reliable

- Q: This american device is labeled as '60hz' but it runs on a universal brush motor, which means that it will still run fine in a '50hz' country without any frequency cycle disturbance, providing i convert the volts, right?I was told that bacause it's labeled on one stores website as '120V AC 60 Hz only' that it probably isnt a true universal motor.But I noticed You can get replacement Carbon Brush and Brush Spring Assemblies - This would futher indicate thats it's a 'true ' universal motor right?

- A 60 Hz motor will operate on a 50 Hz supply, but not at rated speed and capacity. A 50 Hz motor will operate on a 60 Hz supply, but the rpm will be higher than specified. What are you operating and what is it worth to you to stay within specifications?

- Q: The motor I'm talking about is the main large motor in the very bottom of the unit. The unit (which is in the basement) started making a loud humming/squeaky sound. I automatically knew it was probably bearings. I took off the lower panel after I shut it off and reached back there and turned the pulley and it is squeaky yet turns pretty easy. We sprayed some WD-40 on the center and turned it back on and there is no noise now.Is there a way to use a grease gun to grease the bearings normally? If so where would I look for it? Any other suggestions are very welcome!

- Some motors have sealed ball bearings - no lubrication required. Others use common light duty oil. If yours is sealed, you won't have anyway of injecting oil or grease. If you have sleeve bearings, there will be an opening on the end of each motor bell housing where you can inject oil. It may be covered with a plastic cap (mine was a plastic yellow cap/plug about 3/16 dia). The WD-40 is a temporary fix. It will squeak again.

- Q: i am working on project and i have 3-Phase AC induction motors with the following specificationsstandard voltage 230vFrequency 60 Hertzhow can i increase the RPM of the motor if i have generator produces 230v and has 150 amp?and how can i know what is the frequency that the generator produces?

- While induction motors slightly lag the ideal speed, the speed of an AC motor is controlled largely by the frequency of the power used. You can change the speed by changing the frequency. This is done by a device called a Variable Frequency Drive (VFD). Google this for more data. Up to 5HP, you can use singe phase power to drive some of them, with 3 phase output. Above that, almost all are 3 phase in and 3 phase out. I have seen drives with input and output frequencies up to 400hz; some may also run on DC. Most AC motors can be driven at 150% of design speed, many at 200%, with corresponding drops in torque to keep power constant. Over 200%, only a few motors, and up to 400hz is rare. If your generator is 1phase, it puts out 46HP; this is pretty big for 1 phase. If 3 phase, it puts out 140HP. I think you mean 15 Amps. The frequency is designed by the manufacturer; you can use a frequency counter or oscilloscope to measure it. If you are working with a car alternator, know that you can only get 500 to 1000W from it, because it is limited by the physics.

- Q: I have a 1.5hp 220v 3 phase motor driven band saw. I need to run it on a 220v single phase system. The original single phase converter consisted of a 550uF capacitor supplying the third phase winding with the contacts of an NC relay in series with the capacitor. The coil of the relay is from the supply through a resistor to the third phase winding and dropped out when the motor came up to speed. A second 40uF capacitor is from the supply to the third phase winding and is the only capacitor that remains active when the relay opens up (motor is up to speed). I'm looking for a simpler and more reliable solution, as the present circuit is temper mental and old. Replacing the motor is a last resort. Is there a simpler capacitor type converter that can be designed? The saw is only operated intermittently for 10-15 minutes on time, 30-60 minutes off for an 8 +hour period, for a few days a month. It is used for a meat cutting band saw. Any sources, help or information would be greatly appreciated. Thank you.

- Capacitor type converters do tend to be temperamental, but the circuit you have seems to be about as simple as they come. Rotary phase converters are generally considered much better, but are also much more expensive. Another option that may be practical due to the lowering cost of semiconductors, is a is a VFD inverter drive, while the name includes variable frequency you can just as well use it at a fixed speed. Just a couple weeks ago I installed 3 conveyors with singe phase to three phase VDF inverters (albeit wit smaller motor than yours) and they work flawlessly.

- Q: And what fuses would I need?

- You would likely use as a minimum 277/ 480 Volts, the current draw per phase would be120 amps. I'd guess the fuses would be 200 amp.

- Q: What are the reasons for initial inrush curent at start of an AC motor?

- The coils of an electric motor have inductive reactance but very little resistance. The coils initially act similar to a short circuit when the switch is closed and the motor shaft is stationary. Once the motor begins to rotate, the motor develops back EMF (voltage in reverse polarity to source voltage) which counters the source voltage, reducing the effective voltage across the motor coils, and reduces current flow. Back EMF is highest in a motor that is at full operating speed and under no mechanical load. When the motor is under mechanical load, back EMF is reduced until the motor is under full load, increasing the current to full load rating.

- Q: Could an AC motor (synchronous or asynchronous ) work with DC voltage? ;and the opposite, a DC motor with alternative voltoge? is it possible??

- Generally no. There is a type of motor often used in domestic appliances called a universal motor that will work on both ac or dc. Its the exception.

- Q: What is it?

- The resistors act as a load to absorb the power from an AC motor that is acting as a generator. Assume that the frequency of the power applied to an AC motor is reduced at a rate that requires the motor speed to decrease at a faster rate than it would slow down if power were to be removed. In order to force the load to turn at the slower speed demanded by the frequency reduction, the motor produces negative torque, torque that is applied as a braking force rather than a driving force. During braking, the load is driving the motor and the motor acts as a generator. The motor produces a voltage that exceeds the voltage produced by the AC drive. That voltage would tend to charge the capacitors in the drive to an excessive voltage. Circuitry in the drive detects the voltage increase and/or the current reversal and connects braking resistors to draw a compensating current and dissipate the energy produced by the motor.

- Q: i wont to make my slide door to open and close with out use my hand and i wont the electronic map to make itthank for all

- You need a series motor like the one use for drill. By changing the stator coil direction, AC series motor can change its rotation. A DPDT relay can do this task. Use this motor to rotate a gear to control door either open or close. Limit switch installs on both end to stop the door at fully close and fully open position. A reset control is also require to restart the task.

- Q: I'm writing a persuasive essay for school and I need to know how the electric motor by Michael Faraday changed the world during the Industrial Revolution, yet still has a great impact on today's world. I know that without it transportation wouldn't be the same, but what are some other reasons it was/is so useful? (convenience, safety, etc.) Thanks!! :)

- When the electric motor Faraday invented is turned into a turbine; run by wind, water, steam, etc. it becomes a generator and produces alternating current. Thus his electrical motor design has a two-fold purpose. Many products have motors running on the same principle today - vacuum cleaners, power saws and so on - even heating and air conditioning units which force air through buildings and homes.

Send your message to us

YTPEZ (1P54) Three一Phase Asynchronous Motor for Travel Mechanism of Tower Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches