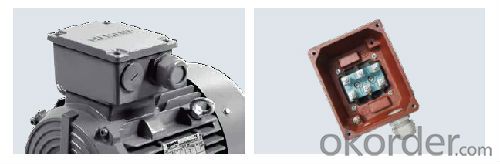

SIEMENS ILE0001 AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit unit

- Supply Capability:

- 300 Unit/Units Per Day unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Information:

| Brand Name: | Siemens | Model Number: | 1LE001 Series | Type: | AC Motor |

| Frequency: | 50 Hz | Output Power: | 0.55-315 KW | Protect Feature: | Explosion-proof |

| Phase: | Three-phase | Certification: | CE | Installation | B3,B5,B35 |

| Place of Origin: | Shanghai China (Mainland) | Efficiency: | IE 1 | Packaging Detail:: | EXPORT STANDAR WOODEN CASE |

| Structure | Asynchronous Motor | Function | Driving | Usage | Universal |

Siemens Motors Advantage:

Prompt Quotation.

Competitive Price

Guaranteed Quality

Timely Delivery.

100% Tested.

Sincere and Professional Service.

Outstanding Finishing Surface.

Strictly and Perfect Management is guaranteed for Production.

Specialized in Manufacturing and Supplying a wide range of Electric Motors since year 2002.

Have Rich Experience and Strong ability to Develop New Products.

Have Ability to Design the Products Based on Your Original Samples.

| Power(KW) | Pole | Model | Power(KW) | Pole | Model |

| 0.75 | 2 | 1LE0002-0DA2□-□□□□ | 0.75 | 4 | 1LE0002-0DB3□-□□□□ |

| 1.1 | 2 | 1LE0002-0DA3□-□□□□ | 1.1 | 4 | 1LE0002-0EB0□-□□□□ |

| 1.5 | 2 | 1LE0002-0EA0□-□□□□ | 1.5 | 4 | 1LE0002-0EB4□-□□□□ |

| 2.2 | 2 | 1LE0002-0EA4□-□□□□ | 2.2 | 4 | 1LE0002-1AB4□-□□□□ |

| 3 | 2 | 1LE0002-1AA4□-□□□□ | 3 | 4 | 1LE0002-1AB5□-□□□□ |

| 4 | 2 | 1LE0002-1BA2□-□□□□ | 4 | 4 | 1LE0002-1BB2□-□□□□ |

| 5.5 | 2 | 1LE0002-1CA0□-□□□□ | 5.5 | 4 | 1LE0002-1CB0□-□□□□ |

| 7.5 | 2 | 1LE0002-1CA1□-□□□□ | 7.5 | 4 | 1LE0002-1CB2□-□□□□ |

| 11 | 2 | 1LE0002-1DA2□-□□□□ | 11 | 4 | 1LE0002-1DB2□-□□□□ |

| 15 | 2 | 1LE0002-1DA3□-□□□□ | 15 | 4 | 1LE0002-1DB4□-□□□□ |

| 18.5 | 2 | 1LE0002-1DA4□-□□□□ | 18.5 | 4 | 1LE0002-1EB2□-□□□□ |

| 22 | 2 | 1LE0002-1BA2□-□□□□ | 22 | 4 | 1LE0002-1EB4□-□□□□ |

| 30 | 2 | 1LE0002-2AA4□-□□□□ | 30 | 4 | 1LE0002-2AB4□-□□□□ |

| 37 | 2 | 1LE0002-2AA5□-□□□□ | 37 | 4 | 1LE0002-2BB0□-□□□□ |

| 45 | 2 | 1LE0002-2BA2□-□□□□ | 45 | 4 | 1LE0002-2BB2□-□□□□ |

| 55 | 2 | 1LE0002-2CA2□-□□□□ | 55 | 4 | 1LE0002-2CB2□-□□□□ |

| 75 | 2 | 1LE0002-2DA0□-□□□□ | 75 | 4 | 1LE0002-2DB0□-□□□□ |

| 90 | 2 | 1LE0002-2DA2□-□□□□ | 90 | 4 | 1LE0002-2DB2□-□□□□ |

| 110 | 2 | 1LE0002-3AA0□-□□□□ | 110 | 4 | 1LE0002-3AB0□-□□□□ |

| 132 | 2 | 1LE0002-3AA2□-□□□□ | 132 | 4 | 1LE0002-3AB2□-□□□□ |

| 160 | 2 | 1LE0002-3AA5□-□□□□ | 160 | 4 | 1LE0002-3AB5□-□□□□ |

| 185 | 2 | 1LE0002-3AA6□-□□□□ | 185 | 4 | 1LE0002-3AB6□-□□□□ |

| 200 | 2 | 1LE0002-3AA7□-□□□□ | 200 | 4 | 1LE0002-3AB7□-□□□□ |

| 220 | 2 | 1LE0002-3BA2□-□□□□ | 220 | 4 | 1LE0002-3BB2□-□□□□ |

| 250 | 2 | 1LE0002-3BA3□-□□□□ | 250 | 4 | 1LE0002-3BB3□-□□□□ |

| 280 | 2 | 1LE0002-3BA5□-□□□□ | 280 | 4 | 1LE0002-3BB5□-□□□□ |

| 315 | 2 | 1LE0002-3BA6□-□□□□ | 315 | 4 | 1LE0002-3BB6□-□□□□ |

- Q: Is the permanent magnet motor a direct current motor or an AC motor?

- Compared with the electric excitation motor, permanent magnet motor, especially rare earth permanent magnet motor has the advantages of simple structure, small volume, reliable operation; light weight; low loss, high efficiency; the shape and size of the motor can be flexible and other advantages, and the application range is very wide, almost all over the aerospace, defense, industrial and agricultural production and daily life in various fields.

- Q: AC motor will i have problems with the alternator? I don't need the AC.can i put a short serpentine belt also?

- Sure. Get a belt for a non-AC model or one of those AC delete setups (pulley, etc) if you could find one for that car.

- Q: my AC motor have 2800 rpm but i need 1500 to 1800 rpm which will be variable value.i can control rpm my self 1500 to 1800 which i need.how can i do this?and is this effect on life of motor?

- you can get tapered belt drives to do this,or electronic speed controllers ,little or no effect on the motor

- Q: Im building a formula hybrid vehicle, and Im wondering what would be the difference from using AC and DC motor

- DC motors are easier to control, especially using digital (computer) systems. DC Control systems are usually more reliable than AC Control systems AC Motors require a sourcde of Alternating Current, but ALL batteries are Direct Current (DC). Therefore, you need what is called an AC Inverter to make Alternating Current (AC) from Direct Current (DC)batteries. This means more expense, AND more parts that could possibly fail, thus reducing the reliability of the vehicle and making it more expensive to repair.

- Q: My dad owns this car and the AC recently went out and he does not have accessibility to information regarding how to replace the blower motor. Has anyone done this, or do you have access to detailed instructions from Chilton's, etc.? I tried to look online, but I came up empty-handed. My dad used to own an auto repair shop, so do not worry about your response being too detailed or technical. Any assistance would be greatly appreciated. Thank you in advance.

- discover the blower motor and unplug the electric connection. clean any rust from the area and reconnect. that could shelter it. I purely did that with my daughter's chevrolet final month here in Michigan. If it makes an unusual noise like a screech, that usually shows the around plastic piece that the motor turns is wiped out and desires changing. That expenses approximately $20.

- Q: I noiced about 2 days ago that when I turn on the ac or heater on my car the blower motor in front of the passenger's seat starts to buzz and vibrate for like one minute and then it stops, I took it out yesterday and I didn't find anything stuck or nothing only that it had some dust, I revised the duct where it came from and found nothing unusual, what can be happening to it? Is it time to change it?

- heater fan, the relay , the fuse or the switch on the dash !

- Q: I have a ton of good magnet wire i stripped off and old motor housing and wanted to build a new motor with it. I started small with wire wrapped around nails and 12 v battery and it worked but it got extremely hot very fast. If i plan to build a 120 volt ac motor then would i have to use some special electronic equipment? Since 12 volts made it burn up then 120 would be even worse unless i could dampen it.I AM NOT TRYING TO BUILD A PROFESSIONAL MOTOR. JUST SOMETHING THAT USES LIKE WIRE WRAPPED AROUND NAILS OR SOMETHING LIKE THAT.

- For wire wrapped around nails or something, use a lower voltage. Look at descriptions of how motors work and compare AC motors with DC motors. A permanent magnet AC motor might work better than an induction motor. Study all the kinds of AC motors. Single-phase AC motors usually need capacitors. If possible, wind the wire on something U shaped and put the rotor between the ends of the U.

- Q: AC motor stator winding does not turn, why the back EMF?

- The principle of an electric motor can be understood in junior high school. It is a device that transforms electrical energy into mechanical energy. The energized coil is subjected to a magnetic field to its ampere force in the magnetic field, causing the coil to rotate around the shaft. Ampere force is the power source of coil rotation. If we see only the power of the ampere force, the coil of the motor will continue to accelerate, which is obviously impossible because each motor has a maximum speed.

- Q: If i hook up a Vacum motor to a car battery will it rum or blow out?

- I assume a vacuum motor out of house vacuum that normally runs on 120 Volts. The answer is will most likely run slowly. Most vacuum motors are something called universal motors which run on AC or DC. There speed is proportional to the voltage and load applied. Since your voltage is about 10% of rated it will run very slowly if it will overcome friction.

- Q: what will happen if dc is applied to ac motor?

- short circuit

1. Manufacturer Overview

| Location | Shanghai |

| Year Established | 2012.10.19 |

| Annual Output Value | USD 1,500,000 |

| Main Markets | Austrilia;Turkey;South America |

| Company Certifications | Certificate of Authorized Distributor |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai port |

| Export Percentage | |

| No.of Employees in Trade Department | 20 persons |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SIEMENS ILE0001 AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit unit

- Supply Capability:

- 300 Unit/Units Per Day unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords