YVF(E)Three一phase Asychronous Motor for Braking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Overview

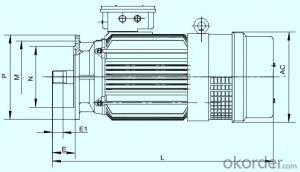

YVF(E) three-phase asychronous motor for brakingv is provided with an electromagnetic brake set between the rear cover of the primary motor and axial-flow fan

This kind of motor is widely applied to the occasions requiring for speed regulation, rapid stop and accurate positioning.

Features

Variable-frequency regulation in a broad range;

High efficiency, small starting current and big starting torque;

Capable of rapid braking and accurate positioning. It is suitable for frequent starting and braking

- Q: I made a three axis CNC router with three CD drives. I was going to make a stepper motor controller board for the CNC but I noticed that the motors are NOT servo motors instead they are hobby motors(the motors with two wires) So is there a schematic anyone knows of that controls a hobby motor with a parallel port? I WILL PICK A BEST ANSWER!!! thank you!

- If you want this router to work at all you need micro stepping and cheap easy plans don't offer this. The plans that do end up costing a lot in parts so it's better to just buy a kit. If you have money you can get good controllers from rutex and gecko drives.

- Q: I looked up blower motors for my 99 Jeep Grand Cherokee online and they have a few VERY different ones:Crown Left Blower Motor, Dorman AC blower motor, etc. Is there not just ONE blower motor? How do I best go about purchasing these correct parts online without having to shell out so much dough?!

- Go to a local car parts place and pick their middle brand. if that still does nothing for you

- Q: What happens to DC motors when they are connected to AC current?

- None of these people answered your question fully, so I will. A DC motor that uses permanent magnets will vibrate at the rate of the AC line frequency, which for the USA is 60 Hertz. However, if the DC motor is a shunt wound motor or series wound DC motor aka field wound motors, then it will rotate. These motors use copper wingdings in the field instead of permanent magnets to produce a magnetic field when current passes through the copper conductors. In fact the universal motors you find in power tools, vacuum cleaners, and blenders use series-wound DC motors that are using AC power to run. If want to know how it is possible for a field wound DC motor to run on AC then let me know and I will tell you.

- Q: The difference and advantage between DC motor and AC motor

- Alternating current dynamo:Advantages: 1.. Simple structure2. low manufacturing costs, 3. maintenance, simple economy.Disadvantages: can not speed up their own, you need to use frequency conversion equipment to achieve speed changes.

- Q: My electric motor will not come on each time. I turn the ac on. especially when it has been cool over night. After driving a while it may come if I have had air coming thur the vent

- Check if there are any loose wires. Something might not be getting a good connection.

- Q: what might be the sypmtoms, if theres a problem with brusehs or/and slip rings of a DC motot and of an AC motor ?whats the solution of this problem ?thanks

- If you isolate your question only to the rings or brushes, you can narrow possible problems down to corroded/worn parts, overheated parts, or poorly installed parts. The symptoms will most likely be the motor not functioning at all, refusing to start itself but will run with a little helper push, noises from the end with the parts, or a completely locked up motor. The solution to the problem is most always replace the worn parts. In most cases ive seen tho, if the rings or brushes have worn naturally (without the help of careless operator), other parts are getting ready to go out (bearings, coils, and such). The symptoms can differ between the types of motors as well and always check the input power source and controller before you pull the motor apart.

- Q: Hey guys. Not to long ago did I replace my AC resistor for my car. Its no hassle to replace but what dawns me is the fact that my old AC resistor that I replaced was burned, it literally looked like it caught on fire. The plastic melted and had some burned holes. This really puzzles me and scares me because I do NOT want my truck to catch fire because of the AC. Would you guys know any reasons why it would just burn like that? anyway to prevent it? I barley use the heater. Living in California you don't have that many cold days here accept the morning and I just use the heater to defrost my windshield and that's it.

- Try following the wires to the ground lead and once you find where it is grounded clean any corrosion and dirt off of if and under the connection.

- Q: ac motor tripping on single phase cause?

- This is probably a split phase capacitor start motor where all or part of the capacitance used in starting is switched out once it is running, and that would be the first place I would have looked as you have done. The rcd rating is about 12 times the full load current and this would not protect it against an overload, so it sounds like there is a fault in the motor or the feed to the motor and the only way to find it is to take the circuit apart and do insulation checks on each bit. Intermittent faults like this are hard to find as when a test is carried out the fault doesn't always show.

- Q: if i have a ac battery pack connected to a motor then does the motor have to be AC or DC

- There are no AC batteries. I do not know what you mean when you write of an AC battery pack.

- Q: for example: 4-poles or 6-poles: which is difference i can see inside motor?

- yes if you can count the number of coils and interpret the winding configuration a motor rewinder at a repair shop can do this easily put it on a known frequency and measure the RPM - easier

Send your message to us

YVF(E)Three一phase Asychronous Motor for Braking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches