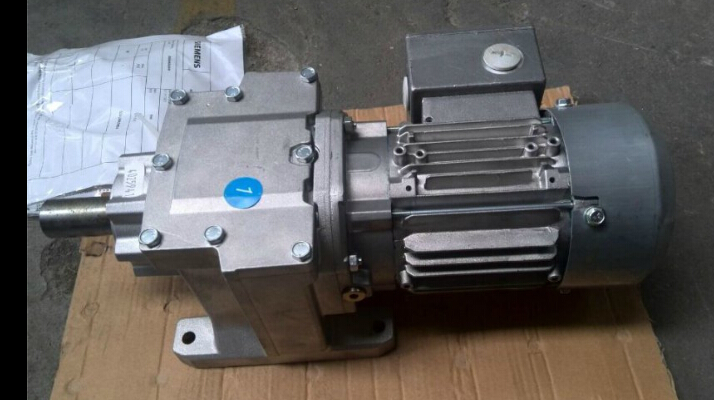

Siemens Original Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: i need to use an electric motor and i need to know how to change it to dc

- U will need a power converer, they sell theses for cars at a auto place, there about $30 for a cheap one that should do for a small motor. A place like home depo might also have this

- Q: wondering if there is any solution for braking motors other than a vfd braking , heard about dc injection braking any idea on how a dc injection braking would work ? . A dc injection braking for ac motors

- The 'authentic potential' decrease fee quotes would be according to potential ingredient. The section-controlled DCpersistent would have a undesirable potential ingredient at decrease speeds, coming near an very almost appropriate potential ingredient at complete speed. The V*A used interior the motor isn't that plenty diverse. The DC motor demands a magnetizing field to be energized (different than PM automobiles), as does the AC. The AC magnetizing present day is extra stable to make certain, yet is calculated by way of greater end drives, such which you are going to see that the 'loss' or 'overhead' of in simple terms turning the shaft devoid of load.

- Q: howv does the AC electric motor differ from DC electric motor structurally. can we use AC 220 volt 60 watt ceiling fan case be used and changing coil and make it DC electic motor of 36 volts if so what power WATT should be given to give same energy output

- I think the simplest solution would be to get a 24V lorry radiator fan motor from a breakers yard and step down the voltage. or go one stage further and power from a photo-voltaic pannel so it works whenever the sunshines and automatically stops at night. rewinding the motor and fixing the commutator, brushes etc is likely to be difficult if not impossible without completly re-building from scratch.

- Q: When an AC motor overheats badly, what is generally the first point or two that it will fail at? And what will be required to remedy the problem?(I see alot of carbonization of the coils in various places.)'m working on bringing an old single phase 120 V, 12 A motor back into operation but I'm a bit new to motor theory and many other things under the sun.I pulled the motor off the table saw it came from, cleaned it up, realigned the extremely misaligned rotor with the stator so it turns easily again BUT it still isn't working, it just sits there and hums it's terrible hum. So obviously the alignment is not the current cause of the motors inability to operate.Thanks for your help!

- There are many case for non operation of ac machine.This trouble shoot will help to find the answer 1.Find the air circulation holes block age 2.Find the carbon brush position and condition. The second point may be the Solution for your problem

- Q: Im wondering how many Volts/Amperes a regular small electric motor can handle.

- Hello, Is it a DC or an AC motor? I am more familiar with DC motors, but AC motors have a few similarities. An electric motor draws very little current at no-load, so even if it's not designed for a given voltage, it may run just fine (and very fast) if you give it too much voltage. Usually DC motors are designed for 12 volts (16 volts max, typically). But they can usually handle 50 volts if there is no load. Of course, if the motor is going way too fast, it may fall apart - the copper windings will fly off the core and the motor will die. If you load the motor , the current increases rapidly. If the motor is stalled (energy applied, but the motor is physically clamped or restrained, it will draw maximum current and will eventually burn up, or if the motor has an internal circuit breaker, it will trip to protect it. A typical automotive DC motor can handle anywhere from 10 amps to 40 amps at 13 volts. If you let the motor run at no load, or a very light load, it can run indefinitely and will never overheat. However, AC motors are a different animal, and can be rated for either 120 volts or 240, or 460. There are way too many variables if you're talking about an AC motor. They are MUCH more dangerous than a DC motor also. If you disassemble any motor, be very careful. Even if you unplug an AC motor, there may be large capacitors inside it which can hold a potent charge and zap you if you touch the wrong thing

- Q: Will a DC shunt motor operated on an AC supply?

- DC motor cannot run on AC source. It just stands still. But you may change the winding connection to form a series motor that can be run on both DC or AC power source.

- Q: Details too ?

- will answer it better than anyone here most likely

- Q: what are some things that use ac instead of dc electricity. Why do some things need ac and some need dc? Also, how are the currents changed to form ac or dc?thank you

- That my friend is a big *** question. (I'll keep it simple) AC =Alternating Current so voltage goes 0v 110v 0v -110v around 60 times a second. DC=Direct Current so voltage goes 12v............ forever (or till your battery goes flat) First AC is far easier to generate, Even cars generate AC and convert it to DC. Cars use DC because you can store it in a battery, which in turn means you can use it to start your car. The sockets in your wall are AC most appliances that plug into the wall use AC, computers and electronics generally convert AC to DC because that's what electronic components need to work. Transformers need AC to work, (I wont go into why), and the transmission networks use very high voltages, like 110,000 volts, then convert it with transformers for use by the consumer AC motors are also far more simple and easier to produce. So most fridges, washers, dishwashers use AC for their motors. they may also convert some electricity to DC for the electronics. AC is converted to DC with a bridge rectifier, which is made up of diodes, which are essentially a one way valve for electricity. DC is generally used for low voltages and AC for higher because AC is easier to switch off than DC. When you switch something off it makes arcs (electrical spark), once an arc has started it is hard to stop, for example an arc might be capable of starting at 1mm but wont stop till the gap is 3mm. So with that, if a switch opens to 2mm a DC arc wont stop, but because AC passes through 0v 120 times a second the arc stops and cant start again. I'll leave it at. There is loads more to it, and some of what I have written is very simplified. If you're truly interested perhaps you should consider becoming an electrician

- Q: What's the UVW representative of the motor, please?

- Three phase alternating current is a form of transportation of electrical energy, referred to as three-phase electricity. Three phase AC power supply is composed of three alternating current potential with the same frequency, equal amplitude and phase difference of 120 degrees. There are many uses of three-phase alternating current. Most of the AC power equipments in industry, such as motors, adopt three-phase alternating current, which is often referred to as the three-phase four wire system. In daily life, the use of single-phase power supply, also known as lighting electricity. When the lighting power supply, use three-phase electricity one relative to supply electrical equipment, such as household appliances, while the other one is the line of three-phase four wire fourth wire, which is the zero line and the zero line drawn from the neutral point of the three-phase power.

- Q: Plz provide the answers in points.. I need it for my school seminar assignment.

- DC generators 1. Best for charging batteries for electric vehicles and rechargeable batteries in all portable devices. 2. Used to run electric drive motors in industrial machinery because DC motors have easier and more precise speed control than AC motors 3. DC generators used to run traction motors in diesel locomotives. 4. Used to run DC welders for specific kind of welding 5. Used to run electrolysis and electrowinning of metals from solutions. --------------------- AC generators --------------------- 1. Used to generate all of the electricity we use in households and businesses. AC has a lot less line losses than DC so is universally used worldwide to supply electricity 2 Used to run transformers which allow the stepping up or down of voltage and current. DC can't do this. 3. Used to run three phase electric motors which are much cheaper than DC motors and provide more available horsepower per pound of motor over DC. 4. Cheaper per kilowatt-hr and delivery charge of power than DC.

Send your message to us

Siemens Original Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords