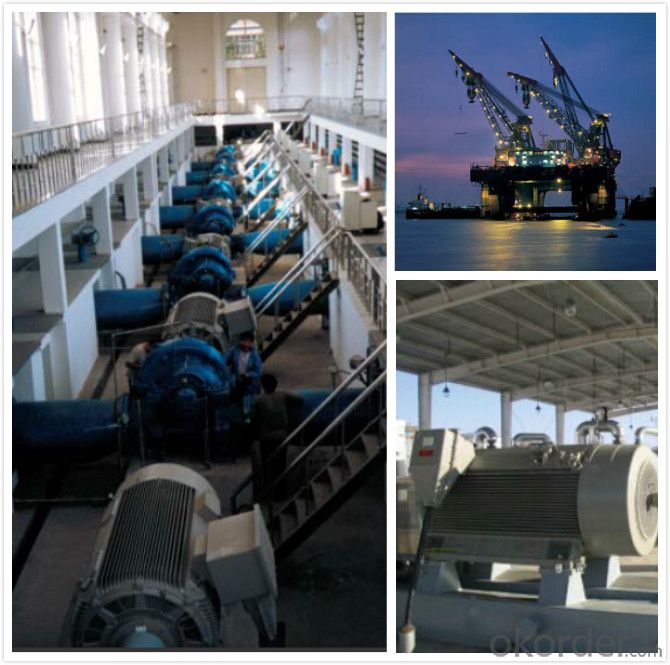

Siemens 1PQ High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: What is the highest 120 volt electric motor on the market. Are they small 1/2hp to 3hp or can you buy them at 15-20 hp.

- 5 horsepower is about the limit for 120 VAC as most house wiring is not up to such a real load. The ratings on vaccum cleaners not withstanding. it is easier to make the motors for 240 VAC, and house wiring can handle the current load more readily. In general, figure 6.5 to 7.5 amps per horsepower for a realistic rating on 120 VAC. Vaccum cleaners claim higher horsepower- but their numbers are usually based on the point where the motor burns out. Few houses have 8 gauge or 6 gauge wire coming from the service panel unless spec'd for it and those would be needed to modest runs to a 5 Horse 120VAC, whereas a 5 horse on 240VAC can run safely up to a point on 10 guage wire.

- Q: will DC motor run on AC supply. justify ur answer

- In an Ac generator...the direction changes as polarity changes......but if Ac is supplied to DC motor....it will not work at all.....

- Q: What is the size of DC motor and AC motor under the same power?

- In general, the DC motor is large in size, but it depends on whether the supply voltage of the two motor is the same.

- Q: I have a small 1/4 HP 220V AC motor, and I want to see if it will run on a regular household 120V AC circuit. Will it work?

- poorly. It will rotate slowly if at all, and may overheat. .

- Q: I have 2 dc motors running off a 12 volt battery charger. It works but the motors run very slow. What can I do to make them run faster. Can I use a power inverter to convert 110v, ac into 24v, dc?

- first check is the current supply on by touching the main wire

- Q: Explain three methods for making the motor spin fasteR?thanksmosqq

- Your motor caused by magnets is probably home made...? This is probably run from a battery. Put 2 batteries on this motor. Do it so that the plus of battery contacts the minus of the next battery then hook the exposed plus and minus of the two batteries to the motor. This will double the voltage and increase the speed. You can continue to add batteries until the motor either heats up to point it gets damaged or spins itself apart. You also go to radio shack and get battery holders that put the batteries in series for you. For the synchronous AC motor like these guys said the rpm (speed) = 120 times the frequency (60hz in USA) divided by the number of poles. Pretty hard to change speed of an synchronous motor on your own better to by VFD. Variable Frequency drive. Be careful with just saying AC motor since you can get universal motors. These will have brushes like a drill or router might have and these can be adjusted through voltage control.

- Q: Whether there is any change if we give ac supply to a dc motor?

- If it is a series wound DC motor with brushes it will run on AC voltage, but the voltage has to be the same. For instance if the AC voltage is 120 then the DC voltage needs to be 120. If it is wound any other way the motor will short out and burn up and maybe trip a breaker or cause a fire.

- Q: A sinlge phase AC motor is needed to lift up vertically a load of 150kg to 200kg using chain and gear. Please help.

- Depends on how fast you want to lift it. With the right gears a tiny motor will do the job, although it may take hours.

- Q: I'm looking for an AC Motor, with high torque (around 130-200lbs/ft) that doesn't use more than 5kw. Let me know your thoughts... Tony

- Its slightly a seize 22 suituation once you've an electric powered vehicle you employ the mains to fee it up yet this comes from potential stations that extra usually than not use gas or coal. in case you employ a diesel vehicle you're nevertheless employing oil yet in a diverse sort. the desirable aspect to apply is a gas cellular vehicle the position liquid hyrogen is switched over to electrical energy with in straight forward words water as a byproduct yet you nevertheless favor to apply resouces to make the liquid hyroden. the desirable aspect to do is cycle or walk.

- Q: Does anyone know the following,the starting and torque as awell as speed and load?and to be picky does anyone know them for a three phase AC motor?

- Starting torque for both is about 250% or more of rated torque. For DC shunt motor, see curve in 2nd source. For ac, see NEMA curves in 3rd source under DESIGN A, B, C, D - FOR AC MOTORS Speed and power depend on motor you buy - check manufacturer catalogs. AC motors typically run a few % below following synchronos speeds: 1800, is most common, also 3600, 1200, 900 rpm. You can use the internet to look for catalogs and more info.

Send your message to us

Siemens 1PQ High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords