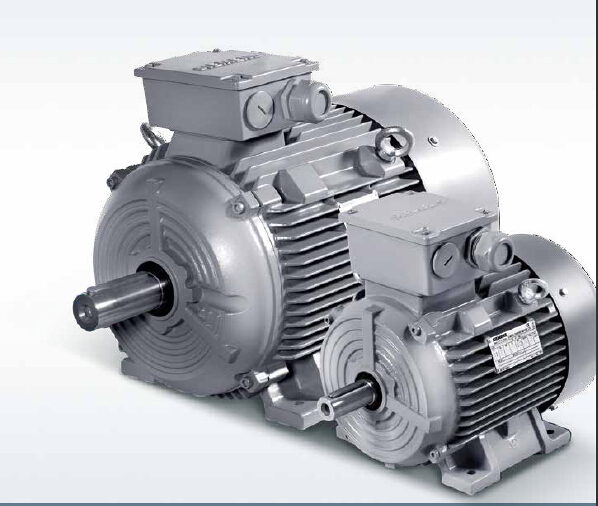

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: its an ac motor, but it spins the wrong way, i need to reverse it.

- As far as I can remember, to reverse a shaded pole motor, you have to install a new rotor in which the spiral in the laminations is in the reverse direction.

- Q: From what I remember about AC motors, one cannot lower the voltage to slow it down- it must be the frequency that is lowered. However, I have an AC wall fan which slows down when the voltage in my house drops. Whenever a microwave or similar high-current load is on the voltage drops slightly and I always notice the fan motor slowing or speeding up when the load turns on and off. Why is it doing this? I am assuming that it is not good for the fan but seeing that it has been running this way for years it must not be that detrimental to it...

- AC motors as the name implies is run using AC/alternating current.. this is best represented by a sinusoidal graph with time in the horizontal axis and voltage or current in the vertical axis.. motors uses the current to produce power which drives whatever it is that's attached to the motor.. power is directly proportional to either voltage or current.. because of this, low voltage/current produces low power and vice versa.. this is the reason why your fan slows down when voltage drops..

- Q: What's the difference between a three-phase AC motor and a DC motor?

- AC motor shell usually made from cast iron, only as a function of protecting and supporting the motor; and DC motor shell is made of steel or steel, except for the protection and support of motor, or part of the magnetic circuit;

- Q: Hey guys, my AC tries to start outside it seems, but then i hear a big BEENG sound for like 4 seconds (as if the AC tries to start). Then it stops. I have a digital thermostat and its showing all 8888. I tried to stop the circuit breaker and restart it to no avail. It's the unit outside that seems to be the problem.ANy clue what's going on here and how much it will take to fix it?

- Sounds like the AC motor's burnt out. Expensive, I'm afraid as the motor and AC pump are a sealed integral unit. The AC tries to start, then the circuit breaker trips due to the internal short drawing overload current.

- Q: What is the size of DC motor and AC motor under the same power?

- In general, the DC motor is large in size, but it depends on whether the supply voltage of the two motor is the same.

- Q: Soybean milk machine AC motor or DC motor is good?

- With a special fragrance, and slightly stimulated; slightly sweet, and accompanied by stimulating spicy taste. Flammable gas whose vapors can form explosive mixtures with air and can be miscible with water at any rate.

- Q: I just needed clarification on the difference between an AC and DC motor.Thank you!

- AC is alternating current, and DC is direct current. In a DC circuit, the voltage (and consequently current) remains constant. In an AC circuit, the voltage varies with time.

- Q: The difference between DC motor and AC motor

- AC motor is divided into two categories: asynchronous motor and synchronous motor. According to the number of stator phases, asynchronous motors are divided into single induction motors, two-phase asynchronous motors and three-phase asynchronous motors. The three-phase asynchronous motor is widely used in industry and agriculture production because of its advantages of simple structure, reliable operation and low cost.

- Q: Is it possible to use a 50 Hz motor to a 60 Hz power supply without using any frequency converter?

- Most, but not all 50 Hz motors will work on the same voltage at 60 Hz and vice versa. I live in NZ where the supply is 230V 50 Hz. When I went to the Chatham Islands where the supply is 230V 60 Hz., my electric shaver ran faster.

- Q: Ok, so I have a AC single phase motor that's 115 volts @ 1800 RPM. If I spin it 1800 times in a minute, can I produce 115 volts? (this would be a generator)

- Possibly okorder /

Send your message to us

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords