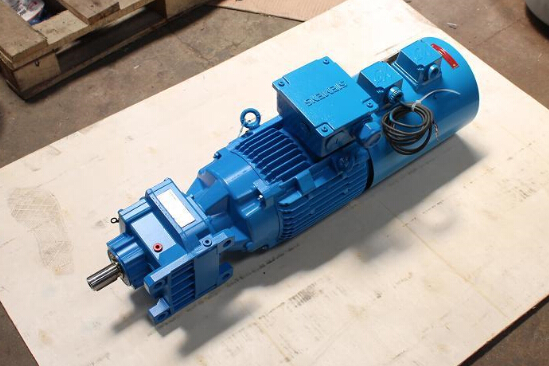

Siemens Original Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Say i have a 400hp ac 3-phase motor.speed is given as 3575 rpm.Does this mean that if left to run on it's own (with 60hz and the related voltage etc) or unloaded it would produce 3575rpm? and the torque would just be power/speed?if this is the case, does this mean that if i loaded the motor with double this torque its speed would half?Basically i'm trying to figure out how to work out the performance characteristic of a motor for different loads given the basic manufacturers data.thanks...

- The okorder

- Q: I have a 1.5hp 220v 3 phase motor driven band saw. I need to run it on a 220v single phase system. The original single phase converter consisted of a 550uF capacitor supplying the third phase winding with the contacts of an NC relay in series with the capacitor. The coil of the relay is from the supply through a resistor to the third phase winding and dropped out when the motor came up to speed. A second 40uF capacitor is from the supply to the third phase winding and is the only capacitor that remains active when the relay opens up (motor is up to speed). I'm looking for a simpler and more reliable solution, as the present circuit is temper mental and old. Replacing the motor is a last resort. Is there a simpler capacitor type converter that can be designed? The saw is only operated intermittently for 10-15 minutes on time, 30-60 minutes off for an 8 +hour period, for a few days a month. It is used for a meat cutting band saw. Any sources, help or information would be greatly appreciated. Thank you.

- Capacitor type converters do tend to be temperamental, but the circuit you have seems to be about as simple as they come. Rotary phase converters are generally considered much better, but are also much more expensive. Another option that may be practical due to the lowering cost of semiconductors, is a is a VFD inverter drive, while the name includes variable frequency you can just as well use it at a fixed speed. Just a couple weeks ago I installed 3 conveyors with singe phase to three phase VDF inverters (albeit wit smaller motor than yours) and they work flawlessly.

- Q: What I want is to generate electricity out from a 2Kw generator alternator and driven by a 800watts AC motor or any AC motor which is much smaller in electricity consumption. I am not thinking of a perpetual machine but to minimize my electric consumption. The AC motor will be connected to the power grid to drive the 2Kw generator alternator.. is this possible? Thanks ahead.

- That type of connection is not going to minimize your electric consumption. It's going to just increase your bill. 800 watt-hours in --> less than 800 watt-hours out. That's a law of physics, and there's no way around it. You're just going to lose energy as heat, in the motor and generator. The 2 KW generator just will not be operated fast enough to get even 800 watts out. You would be lucky to get even 400 watts out of a hook-up like that, with 400 watts going up as extra heat.

- Q: pump specification abbseallesspumps,hmd kontro lcie04atex6152 model

- A lot of motors have 6 wires for the three windings, so you can connect them as star or delta, as required with a star delta starter. The voltage ratings will tell you though. If it is a 380V, 415V, 440V etc. motor and it is connected as star it has a lot less power. If its 220 you have to figure out whether that was for a 127/220 or a 220/380 system. As a check, ((W x 1/PF) / Amps) from the nameplate gives the phase to neutral voltage, or W/A is close enough to tell. Always check the running current when you have installed a motor. Don't forget that the phase rotation may be important for a pump. If a water pump goes backwards there is steam and boiling water everywhere.

- Q: How to control the speed of AC motor

- How is the motor controlled?:Motor control refers to the motor start, acceleration, operation, deceleration and stop control. Depending on the type of motor and the use of the motor, there are different requirements and purposes. The motor is controlled by motor to achieve the goal of quick start, quick response, high efficiency, high torque output and high overload capacity.

- Q: if a ac supply is given to dc motor why the motor coil burned?

- That's why it`s called ac - alternating current. The voltage goes back and forth along the 2 wires, whereas in a dc - direct current the voltage only flows in one direction along the wires, in one way and out the other.Guess you need to get another motor. Look below to better understand what went wrong

- Q: AC motor

- In an induction motor, the current that produces the rotor’s magnetic field is induced by the movement of the rotor conductors through the stator’s magnetic field. The rotor conductors move through the stator magnetic field because the rotor speed is less than the speed of the stator magnetic field by an amount called slip. Synchronous means “happening, existing, or arising at precisely the same time” or “recurring or operating at exactly the same periods.” In a synchronous motor, each revolution of the rotor corresponds to exactly one revolution of the stator’s magnetic field. The synchronous motor is named for the exact, turn-for-turn, matching of the speed of the rotor to the speed of the stator magnetic field. The principal of the induction motor requires a difference between these two speeds. There are other important differences between induction motors and synchronous motors. There are also different types of induction motors and different types of synchronous motors. However, it is the difference or lack of difference between the rotor speed and the speed of the stator’s magnetic field that is the defining difference between induction motors and synchronous motors.

- Q: DC motors vs AC Motors?

- What is your question?

- Q: When the ac is on all lights dim (dashboard and headlights). All other functions slow down (wiper, windows and power antenna). Engine runs great when ac is off - no overheating.

- Check to make sure ac pulley is spinning and or that your fans kick on

- Q: Comparison of AC motor and direct current motor

- Disadvantages of DC motor1. direct current motor manufacturing is more expensive2. carbon brush

Send your message to us

Siemens Original Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords