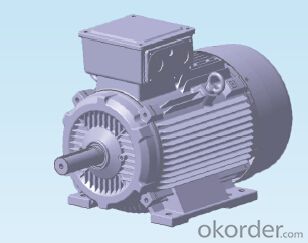

TECO AC Motor High Voltage

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Brand Name: | TECO | Model Number: | HXR 400 Series | Type: | Squirre Cage Motor |

| Frequency: | 50.2 Hz | Output Power: | 350 KW | Protect Feature: | Explosion-proof |

| Phase: | Three-phase | Certification: | CE | AC Voltage: | 690V |

| Place of Origin: | Shanghai China (Mainland) | Efficiency: | IE 1 | Packaging Detail:: | EXPORT STANDAR WOODEN CASE |

| Structure | Asynchronous Motor | Function | Driving | Usage | Universal |

- Q: What is the highest 120 volt electric motor on the market. Are they small 1/2hp to 3hp or can you buy them at 15-20 hp.

- 5 horsepower is about the limit for 120 VAC as most house wiring is not up to such a real load. The ratings on vaccum cleaners not withstanding. it is easier to make the motors for 240 VAC, and house wiring can handle the current load more readily. In general, figure 6.5 to 7.5 amps per horsepower for a realistic rating on 120 VAC. Vaccum cleaners claim higher horsepower- but their numbers are usually based on the point where the motor burns out. Few houses have 8 gauge or 6 gauge wire coming from the service panel unless spec'd for it and those would be needed to modest runs to a 5 Horse 120VAC, whereas a 5 horse on 240VAC can run safely up to a point on 10 guage wire.

- Q: We rewound an ac motor but when we tested it,in a jog, one of the coil got burnt. We checked if there was a wrong connection but there was none. We checked also the number of turns,the size of wìre. We rewound the burnt coil,and test again,the same thing happened.We're wondering why it was happened?.Please help. . .

- The basic reason is too much current, so need to find the cause of that. I have had experience with a motor that drew far too much current on no load, and continually burned out, and it turned out the field lamination were skewed so that the field was not properly aligned magnetically. This did not cause poling, but the problem was visible when the field was inspected. This was a manufacturing defect. Other reasons may be shorted turns, or the laminations are not well insulated, as each is supposed to be insulated from the next. I expect you have already checked for poling and that the shaft does not have excess play. I don't know what the effects of a bad rotor are. I guess the winding causing the problem can be tested and compared with others on the bench, without the rotor. Apply a low voltage from a transformer to the winding and measure the current, comparing with other identical windings. When you say tested in a jog: To me jogging is pulsing the motor to step it along a bit. Could this be grossly exceeding the current rating? I guess a particular coil would tend to burn out first, but the others would be hot too. In the end the rated current should not be exceeded for more than a few seconds, then wait for it to cool down. Some larger motors have starters that prevent the restart until it has cooled down. It is also possible that a supply phase is bad, possibly due to a faulty contactor or connection that has high resistance..

- Q: I've heard from a couple repair folks $300 - $500. It's only a fan motor, how hard can it be?

- Depending upon the size of the motor, it is about $150-$250. Labor is about another $150. Accessibility to the motor is a driving factor for labor.

- Q: How is frequency is efecting when a motor running by electric power,What is the relation of KW with FREQUENCY?

- Dear Meetantacheri, I am not sure which frequency you refer to: 1) The Power Supply Frequency You need to look in your Ordinary Level Physics Books or on the wwweb at: Synchronous AC Motors Asynchronous AC Motors 2) The Rotational Speed of the Motor: For a DC Motor this depends on whether the rotor and stator are Series or Parallel Connected and the Mechanical Load that is on the Motor. For a Synchronous AC Motor you get field slippage if the mechanical load is too high I am not sure what you mean by the kW / f part. If a motor is overloaded it slows down, takes a lot of current and the power consumption rises. This overheats the motor and the winding are destroyed. (see back-EMF)

- Q: how to connect ac motors?

- 1 Confirm that the motor is a 3 phase AC motor. This information will be on the motor faceplate. It also can be noted that the motor has 3 connecting wires, rather than 2. Confirm from the motor faceplate the operating voltage that the motor will require from the power distribution system. 2 Figure out the direction that the motor will turn. The motor nameplate and motor manufacturer's information should explain the needed wiring to make the motor turn in a particular direction 3 Attach the motor power leads. Wire the 3 motor leads to the 3 phases of input power. Do not use the neutral line. If the motor does not turn in the desired direction, swap any 2 of the 3 motor wires to reverse the direction of rotation of the motor.

- Q: What's the big deal. Over 40 yrs. ago right here in the U.S. I saw an electric motor with carbon fields that were(permanent magnets), compressed carbon and they were just glued to the inside of the motor case, A complete motor could be made entirely of carbon very easily. Why haven't we done so here in the U.S.?

- Carbon is lined, wireless is in, remotes are trendy, signals are well ..... , frequecies are ........ hey, gramps, dont try to hp an engine.... I am over 50 and still strong as an ox, you should be 60s

- Q: A sinlge phase AC motor is needed to lift up vertically a load of 150kg to 200kg using chain and gear. Please help.

- Depends on how fast you want to lift it. With the right gears a tiny motor will do the job, although it may take hours.

- Q: I am looking for ideas on AC electric cars. i have seen the kits that use an AC motor and an inverter unit to convert the battery power for use in the motor. I am wondering if there is any advantage to using a VFD and an appropriate size generator? I know locomotives use the motor/generator set up with good efficiency. if i wanted to use a 20hp induction motor i wonder how i would pick a VFD and a generator so as to make a reliable set up? thoughts?

- The Toyota Prius uses an AC motor Nimh batteries and a 4 cylinder petrol motor. It has all the control circuitry for regenerative braking, etc already developed. It has no provision to charge the battery from teh household supply. All power comes from the petrol motor. There are 3 models shown at the site below Electric Motor Operating Voltage 1997, 288V 2000, 273V 2003, 500V Power 1997, 40hp 2000, 44hp 2003, 67hp

- Q: . . . They have brushes, but if they are DC, it sure is hard to figure out where the AC gt; DC transformer would be.

- They have both ac and dc dremel tools..some have cords on them and some are totally battery operated....they do not have a transformer on them..they are either ac or dc..but none or ac and dc also..

- Q: Haven't connected it yet.

- GOOD EXPERIMENT AND YOU BURNT IT WELL ! WHAT IS THE DC MOTOR VOLTAGE RATING ?? HOW MANY RECTIFIER YOU USED ? HOW YOU CONSTRUCTED THE RECTIFY CIRCUIT? HALFWAVE OR FULLWAVE ? FULLWAVE PRODUCES 207Vdc ! HALFWAVE PRODUCES ABOUT 115Vdc, BUT NOT GOOD TO RUN DC MOTOR WITH HALFWAVE. YOUR DC MOTOR IS GONE, TRY ANOTHER ONE THAT MATCH WITH THE VOLTAGE.

Send your message to us

TECO AC Motor High Voltage

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords