Bridge Tunnel Formwork System for Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. CMAX Bridge Tunnel Formwork System Description

CMAX Bridge Tunnel Formwork System is designed to reduce material quantity. A compositional steel formwork system mainly used in the building which has regular structure without beams, the excellent formwork system can make the integral pouring for the wall & slab easily achieved.

2. Main Features of Bridge Tunnel Formwork System

- No assembling, easy operation with formed formwork.

- High stiffness, make perfect shape for concrete.

- Repeatedly turnover is available.

- Widely applied range, such as building, bridge, tunnel, etc.

- We can special design according to any requirements.

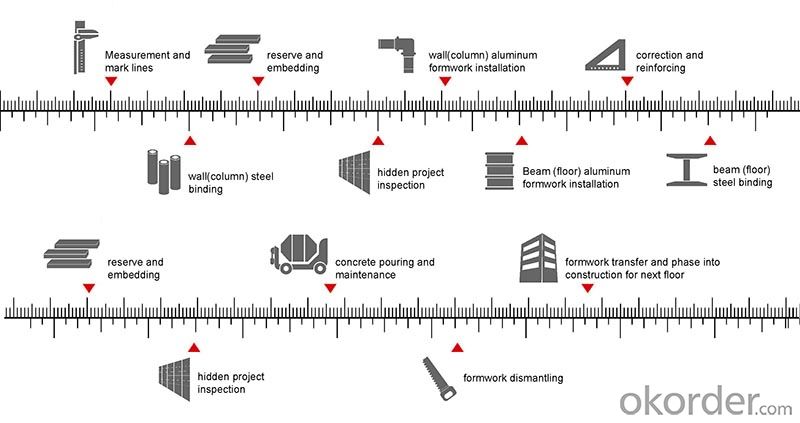

3. Construction Process

4.CMAX Bridge Tunnel Formwork Projects

5. FAQ of CMAX Bridge Tunnel Formwork System

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- It is best to use the high turnover times, can also be used as the use of the beam die, more cost-effective

- Q: For example, lining, invert, bias and so on words,, to answer the full thank you

- Inverted arch: the general shape of the tunnel are horseshoe. Then the bow that you look up at is called an arch or vault

- Q: What is the vault vault seal and dead seal please give a detailed drawing of the drawing bar do not know how to do?

- Directly in the template hole, make a steel plate bolt

- Q: How to put the positioning point is based on what is mainly based on my novice, do not

- The first measurement group with total station will be five points (template center, 2 large side mode along the point, 2 small side mode along the projection point) in lofting invert, with nails into the inverted arch concrete as a symbol, and note the nail surface elevation

- Q: How to fill in the tunnel template

- The template is firm and smooth, there is no error, such as leakage

- Q: How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q: How to design the general layout of the tunnel construction organization design

- I need to contact you to provide a template..

- Q: How to calculate the lining formwork trolley in the tunnel construction, is the fixed assets or the turnover materials?

- In the construction of the tunnel lining template can belong to the low value consumables in accounting, purchasing back into low value, and share in the future cost of 50%, scrap reamortization into 50% of the cost of this method is of low value consumables 55 amortization method; fixed assets, equipment car belonging to the class the asset depreciation period of 10 years. The lining template trolley for a device, rather than separate accounting, and the template should be turnover materials? Added: I engaged in casting model in the low value consumable, car is of course equipment assets added: template is a collar with the repeated use of the low value consumables, which belongs to the class of tools, you can also be classified as turnover materials, but according to the use of reasonable cost sharing principle after ask: you the manufacture of accounting, and it is in the tunnel construction, the construction enterprise to buy trolley. I personally feel that the template should be separated from the car accounting, so more true and accurate.

- Q: I would like to ask the high-speed rail tunnel invert small side wall and arch with the small side of the wall of the hanging formwork of what a good method?

- Die casting. Install the inverted L hanger on the side wall.

- Q: 12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- Seven hours after the maintenance of formwork, pouring a every day is no problem, that is to say a month to about fifteen die casting.

Send your message to us

Bridge Tunnel Formwork System for Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords