API Cast Steel Check Valve Butt Welding in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

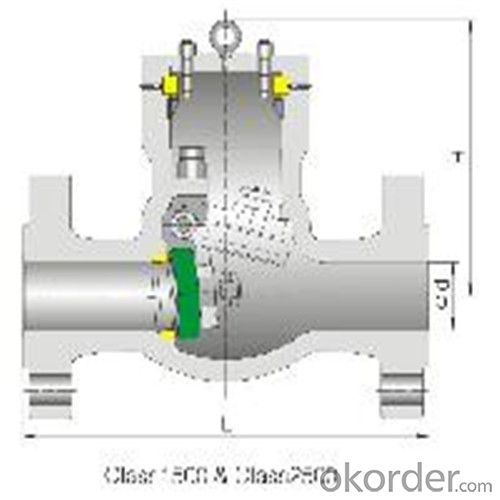

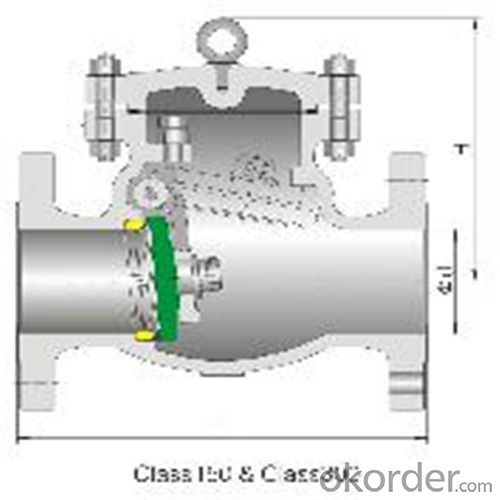

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Chev 350 in marine use. Made horiffic exhaust noise, especially with increasing throttle. Cam seems fine still, but the rocker on #5 exhaust was somewhat off to the side but still touching the side of the valve stem...but stem bent. What would cause this and is this the cause of the loud combustion sound (like a spark plug out of it's hole?

- do a compression check on #5 cyl. also do a cylinder leakage test. You can do this by taking the schraeder valve out of the end of the hose for the compression gauge. then apply compressed air into the cylinder with the piston at TCD. If the exhaust valve is bent and not sealing the air will escape out the exhaust. Sounds like maybe the valve stem to valve guide clearance is too tight and the valve hung open in the guide and smacked the piston. Also with the compressed air in the cylinder you can remove the valve spring and rotate the valve and slide it up and down in the guide to check for binding in the valve guide. Either way it kind of sounds like you'll have to pull the head to replace the bent valve.

- Q: I am being sent for a level 2 Ultrasound Thursday because my previous US showed one of the babies valves was enlarged. She said all 4 chambers were there but she was very vague on what this means. Care to shed some light?

- ?UPDATE? We went to the US today and the heart was 100% HEALTHY!! There was nothing wrong with any anatomy of baby girl. The doctors there said they are completely confused as to why my Doctor would tell me the baby might need heart surgery when she wasn't even 100% on the issue and even if it was due to positioning like she 'claimed' at first, then a Level 2 US wouldn't be necessary. I'm just so grateful and thank God that my baby is ????!

- Q: I am replacing the Camshaft, lifters, and timing chain on a SBC 350. The motor is still in the car and I have the valve covers and manifold removed (and other components). The camshaft break-in procedure recommends removing the inner valve springs and running engine at 2000-2500 rpm for 20-30 minutes. MY QUESTION: I have the valve spring compressor tool to remove the springs. HOW do I prevent the valve from falling into the cylinder when I remove the spring? Can I conduct the break in without removing the inner valve springs?

- the reason they want you to remove the inner springs is so that there won't be too much valve spring pressure pressing down on the cam lobes. Too much valve spring pressure on a new cam will eat up the cam lobes. You can also find some weaker valves springs to run just during the break in and then swap them out for the correct springs you are going to run permanently. The easiest way to keep the valve from falling in the cylinder is to use a compression gauge hose. Remove the schraeder valve from the end of the hose that screws in the spark plug hole. Now you can connect an air hose with compressed are into the cylinder. that's how everyone I know has ever changed valve springs.

- Q: i'm being charged $300 to replace a 75gallon water heater valve, is that too much?

- on the high side 60 bux other than that you can get half a new heater for 300$ crazyness/

- Q: how to adjust the valves on a 20 horse power briggs and stratton engine on a sears craftman rideing mower model number 917.276824

- you shouldn't have to ! unless you have burnt a valve,

- Q: I just dropped my 3rd valve slide from my trumpet on the ground. It fell with the curved end first. I can't see any dents and it doesn't look bent, but I oiled it and everything and it's really hard to move. Could it be bent? How can I fix it?

- Be sure that it is aligned correctly when you place it back in the valve casing. When you are putting it back in, it has to turn until you hear a click, indicating that the valve guide has fallen in the right space. This aligns the valve with all the ports. (The valve guide is a small plastic piece located under the valve spring. This valve guide must snap into a little notch inside the casing. When it does, the valve will be perfectly aligned. You will know when the valve guide is in the right place because you will feel and hear a click and the valve will not rotate any longer.) After thorough cleaning, oiling, and correct valve placement, if you still notice it sticking, take it to a repair shop to have it chemically cleaned. They are typically very good and will ensure your trumpet is in proper playing condition.

- Q: Why is the atrioventricular valve in the right ventricle called the tricupsid valve and the atrioventricular valve on the left ventricle called the bicupsid valve?

- The TRIcuspid valve has 3 pointed flaps; the BIcuspid valve has 2 pointed flaps, and a cuspid is a point (just like your bicuspid teeth have 2 points).

- Q: My 3rd valve keeps getting stuck when i play it, i have valve oil, but its just not working, help please

- There are several possibilities. You may have buildup on either the valve or the casing. Cleaning it thoroughly should normally remove it, but every once in a Blue Moon it pays to take it in and have it professionally cleaned. They can inspect it at the same time and tell you if you have a bend or a ding in the casing. Sometimes they are really hard to spot, especially if they are hidden in one of the crevices of the detail work. A really good repair person can stick a scope down there and tell you if you have some kind of blockage in just a few minutes. The only way to really clean inside the casing yourself is to get a good bottle brush that fits inside with just a little bit of resistance. You should really get someone to show you how to do it the first time because you don't want to go scraping up the insides. There is one other possibility that is kind of rare. Sometimes you get some gunk up under the valve button and it sticks when you push it down. You should normally be able to see this just by looking underneath however. Best of luck and I hope you find your sticking point and are able to set it free.

- Q: Hi, in the heart, blood flows through the AV valves and enters the ventricles once the atria have filled up with blood. What opens the AV valves? Fluid pressure from the blood or the SA node pulses?

- The opening and closing of the atrioventricular valves is controlled by the differences in pressure across them: When blood passes from an atrium to a ventricle, the atrioventricular valve is pushed open (and the papillary muscles relax and the chordae tendineae lose their tension, becoming slack). At the next stage in the sequence the ventricle contracts. This forces blood out from the ventricle into the artery via which it leaves the heart. This contraction of the ventricle and the corresponding increase in blood pressure within that ventricle also presses the cusps of the atrioventricular valve together until their edges meet, closing the valve. At the same time, the papillary muscles contract and the chordae tendineae tighten - both of which also help to prevent the cusps from enabling the atrioventricular valves to open. When in the next stage of the sequence the ventricle relaxes and the atrium contracts, the blood pressure situation is reversed, the relaxation/tension of the papillary muscles and the chordae tendineae also reverses, and the atrioventricular valve allows blood to pass from the atrium to the ventricle again.

- Q: how long do people usually live after mitral valve repair?

- Very basically: The procedure is open heart and entails a complex system of sustaining life outside your body. The complications can vary. If you get a mechanical valve placed, your risk of embolus increases. Emboli can cause strokes and/or a fatal episode. However, once one recovers from either surgery (typically a short stint in the ICU but varying by the individual) the quality of life improves to better than pre-op. The need for a replacement may arise down the line. Barring any blood clots or infections, a MVP repair/replacement surgery does not by itself indicate anything about how long a patient survives post-op. A repair surgery tends to yield fewer long-term complications simply because no foreign tissue or synthetic material was introduced into one's system and the whole procedure is significantly lower risk in terms of infection. The risk of failure of a repaired valve is significantly lower than that of a replaced valve. Lots of variables influence the outcome though, and if this is a personal matter, I strongly suggest you speak candidly with your cardiologist. Bottom line: Repair surgery is generally safer and can allow the patient to live life fully.

Send your message to us

API Cast Steel Check Valve Butt Welding in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords