API Cast Steel Check Valve 250 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

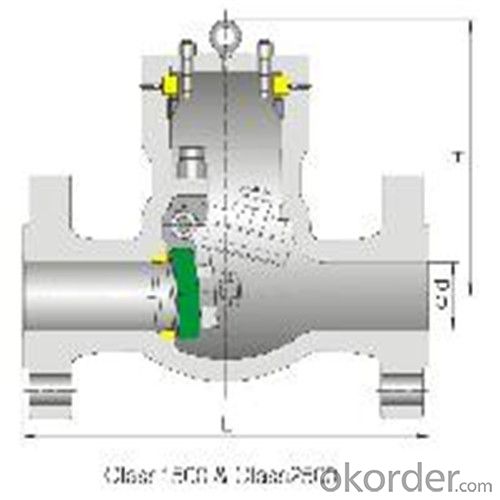

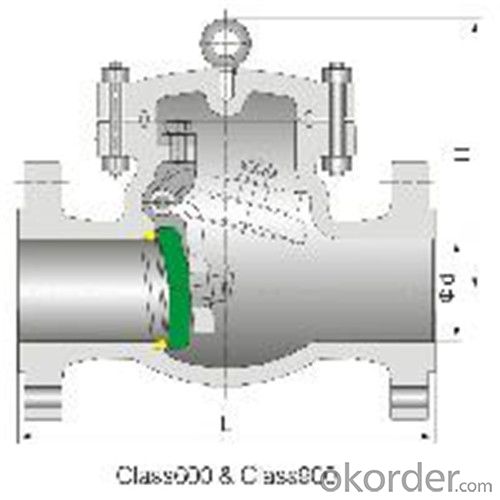

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Im living in an a house previously own but abandonded , and im trying to get water, the thing is the pipe where the shut off valve is is dettached , and i dont know where to reattach it nor do i see the missing pipes to reassemble what does the main shut off valve attach to in my house?

- You have the main water line outside that feeds everyone. Look for a man hole cover and remove it. You should see the turn off valve there. There may be a pipe unit that the county removed so the water could not be turned back on. Call the country and ask for the water to be turned back on. If you are talking about the line after it goes onto your property then it's just a large pipe that comes into your home somewhere. They normally put a on/off valve at that point that allows you to shut the water off inside the home. If the pipe inside the house is detached from that valve then someone most likely cut it and took out a section. You would have to turn the water out at the manhole so you can open that valve and drain the water out of it. Then using a torch/solder/pipe sleeves, new pipe etc solder the replacement piece in place. Remember water in a pipe will not allow the pipe to reach soldering temp without creating steam, which can burn you. Hope that helps....

- Q: I was told on Tuesday that i have mitral valve prolapse and that i inherited it and that i will be fine. Well i take toporol xl 50 mg because the mitral valve prolapse makes my heart beat fast. For the past week i have noticed that my chest/lungs get tight, kind of like i have congestion in my chest, it comes and goes and sometimes its really bad and sometimes i can tolerate it. Is this normal for someone with the mitral valve condition. My cardiologist didn't go into details about the symptoms and i'm wondering if i should go see another doctor. I do have a sniffly nose and was wondering if this could be symptoms of a cold or something else. Any one out their with my condition having the same problems??? If so what is it???

- I also have this condition and I also take Toprol every day. If I forget to take it I know by noon I didn't. My heart really runs fast. I also have the tightness in my chest. AT times i feel like my heart is turning over, now that is weird. I am with you on not knowing what to do, one Dr says leave it alone another says fix it. I am not much help but I understand your thoughts.

- Q: i have a 8v fiat punto...is it much work to add 2 valves to make it a 16v?

- Ha...ha...ha

- Q: i have a zone that - when turnd on by timer or manually only about 1 foot of spray comes out of sprinkler heads (used to wk fine). When i turn the ittle screw on top of valve (its about the size of a dime) water pressure comes up and wks fine - only water leaks at screw and when zone comes on next time NO pressure??? metal valves were just replaces about 1 yr ago.

- It's hard to say exactly what's wrong without knowing what type of valves you have since different valves have different components. In any case, I'd start by checking that the bleed screw and/or handle (depending on type) and that the flow control screw or handle (again depends on what make/model you have) to make sure they are in good condition and properly set. Be careful when turning these screws or handles don't force them past the normal stopping points. If that all checks out, there may be some dirt or debris stuck in the valve that's not allowing the diaphragm to open all the way.

- Q: for a big block chevy,best way to adjust valves and rockers

- ok, take the valve covers off and start your car(let it idle)take the first 1 and loosen it until it starts to tick,then tighten it,until it stops and then give it another 1/2 to 3/4 turns more and do the rest the same way.an old time mechanic told me that way,and it works too.

- Q: In one of the two bathrooms - that we rarely used - I recently found that shower has now only hot water running. The valve is Moen brand with a single knob. On turning this, I get no cold water, but just hot water. I removed the knob, and decided to maybe replace the cartidge, but could not make any headway, after removing the acrylic knob. First, do I need to remove the cartridge?If yes, how? Is it possible to remove it without removing the back-plate glued to the Tile walls? Will appreciate detailed instructions to remove or fix the valve?thanks

- the valve should have a c shaped clip holding it in. do that with the water shut off. if you have cold water to the tub spout, maybe the valve body is clogged with sediment, or a CW valve has collapsed.you have to remove the back plate to access the valve body.

- Q: And' the valve leaks......Can the valve be unscrewed from the tank for replacement? Or can the valve be serviced with a new gasket perhaps?

- Go to the following site and enter the Model of your water heater in the box provided Click on the Magnifying glass. This should give you a list of all the parts for your water heater.

- Q: -air pressure of 40 psi only -run on 12v or 250 vac-no need for half open or any of the options i just want it on or off-it will be for a costum use so i dont need any special designs for it any thing will work -it also can be change from gas to water if

- With okorder and buy one on-line for about $25 and get it in a couple days. Look for thermoplastic valves rather than brass ones, you will save a lot of cash that way. And by the way, if this is really for costume use, you really do not want to use 250vac. That will fry your butt for sure. Stick with the 12vdc.

- Q: Hi guys, my parents had me install a new faucet in their kitchen sink. It works great and everything, but after the install the hot water pressure basically decreased greatly. The cold water pressure is fine, but I believe after I had turned off the hot water at the shutoff valve, something in the valve got messed up and is blocking the water supply.

- Kitchen Sink Pics

- Q: like my Acura has a 16v 4clyinder engine , and i dont know what valves does , the more vavles the faster?

- Your engine is essentially like a vacuum cleaner only it pulls in filtered air that mixes with filtered gasoline. The valves let the fuel/air mix into the cylinder on the piston down stroke or intake stroke. The cylinder actually draws the fuel/air mix in and then compresses it with all valves closed and then it fires driving the piston back down on the power stroke. Coming back up the piston pushes the exhaust gases out through the open exhaust valves. They discovered that there is less resistance with more valves verses trying to make one or two really big valves. In older cars there were only two valves per cylinder. The intake valve was bigger than the exhaust valve but not by much. With four valves per cylinder, the piston uses less energy to draw the fuel/air mix in and push the exhaust gases out. Better effieciency equals more miles per gallon and more horse power when compard to an engine the same size with only two valves per cylinder. Good Luck!

Send your message to us

API Cast Steel Check Valve 250 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords