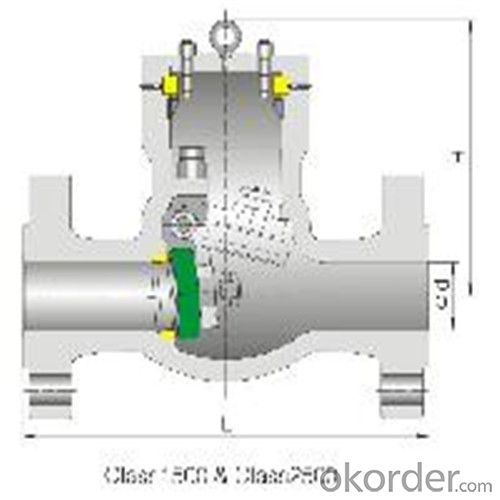

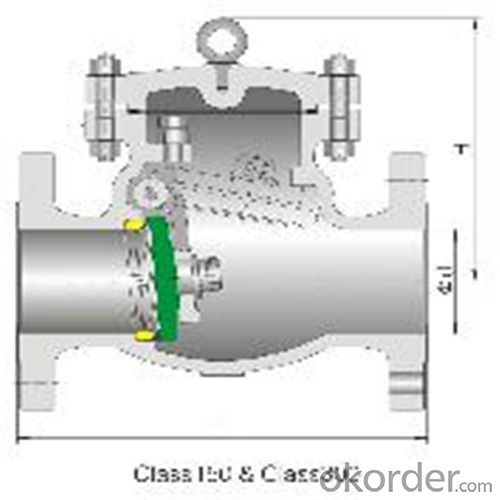

API Cast Steel Check Valve 600 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: heater control valve is leaking

- Do it from underneath. Drain the cooling system and cut the short hose between the heater core and the valve with a sharp knife. Unfasten the actuator cable, loosen the clamp on the heater hose and work the heater hose off it. Use the sharp knife to slice the remains of the short hose off the heater core... be gentle because the soft pipe is easily deforned (which is why you must not try to wrench it off). Put a replacement hose on the new valve and reassemble. When you refill the cooling system be sure to purge the air by opening the bleeder nipple on the upper radiator hose housing at the engine until a steady stream of coolant comes out. Watch out for the sharp edge of the catalytic converter shield! I have a scar on my wrist from learning that the hard way. EDIT - I forgot to mention - if the cable seems to be misadjusted on the valve when you are done, remove the passenger side of the console and look at the mixer linkage in there. The cable housings often slip in the clamps.

- Q: ok, after lots of exploring around online and from some great answers from this site I have found the problem to my explorer. The torque converter solenoid mounting clip broke. thats it!! new question, do i have to take off the valve body to remove the solenoid. If so any tips? its way new territory for me. I hate automatics!!

- What are you? 9 years?

- Q: hi im 13 years old and i am having my tricuspid valve repaired or replaced the doctors do know what they are going to do yet.what is the success rate of the operation ?and whats the survival rate of the operation ?all other info would be appreciatedthanksalex

- Any type of valve surgery involves exposing the aorta of the heart, therefore it is a form of open heart surgery. Over time, this has become a relatively basic procedure for heart doctors and it has a success rate of almost 80-95%. There is a chance that you might need another surgery afterwards, but that only happens in about 5-10% of patients that get the surgery. The survival rate for this operation is very high and only 5-10% of patients experience any negative effects during the surgery. This includes infection, stroke, allergic reaction, or bleeding. I will keep you in my prayers Alex. Best of luck to you!

- Q: I wanna do it myself My dad knows how But i must buy the parts I have a rmz250 and i was wondering if u can jus buy valves and seals and jus put them in without grinding since the seals are new i heard u must gring the seals to get the valves to sit flush againt the metal serface but cant u jus buy new seals and retainers and put that in plus the valves and ur done?

- It all depends upon the wear in the cylinders of the engine. Usually they are honed and made smooth again prior to installing the new rings, seals, etc.

- Q: I have mitral valve prolapse and I don't get why only some people get chest pains? and what causes people to get chest pains with M.V.P (mitral valve prolapse), like me. PLEASE HELP!!!!!!!

- Does Mitral Valve Prolapse Hurt

- Q: Valves regarding WC's

- The proper names of the two valves in a typical home toilet are the flapper valve and the ballcock valve. The flapper valve sends water from the tank to the bowl during the flushing of the toilet. The ballcock refills the tank and also sends a small amount of water to the bowl during the flush.

- Q: what the valves adjustment spies in the 1979 Mercury-marine engine, 6 cylinder in-line 165hp 4.089L?

- There are 2 different ways, with the engine warm remove the valve cover start the engine and 1 at a time back the adjuster nut off till the lifter starts to click and tighten it 3/4 of a turn going 1/4 turn at a time this is very mussy with oil all over everything. The easiest way is to turn the engine to number 1 TDC and back off the adjusters till you can just turn the push rods with your fingers and then retighten 3/4 turn do this in the following order #1 E+ IN #2 - IN #3 E #4 - IN #5 - E--- then turn the engine 1 turn to number 6 TDC and adjust the remaining valves the same as the first in this order # 2 - E # 3 - IN #4 - E #5 - IN # 6 IN+ E Then reinstall the valve cover and your done much cleaner way

- Q: I've been working on cars since around march of 2012. I new. I have a set of 305 heads that were really dirty. It came from a 79 camaro that never had an Oil change. I took the valves out and the valves are pretty burnt. I was wondering If I cleaned them up would they still be good to use? The edges aren't rough or anything. Just let me know what is need to know please. The heads I know are still good.

- hey why dont you go down to your local machine shop and ask a few questions,try and angle a cleanup job to trade for labor and experience.in other words,why dont you go ask your dadlove that commercial

- Q: I've just been told that I need to replace the valve cover gasket on my 97 Volvo 850.....to the tune of $650.00 .....ouch.....is it that difficult to fix?......can you use the red gasket sealant? is there a difference between the head gasket and the valve cover gasket.......yeah I know there probably is.......but when I look on line all i can find is head gaskets......no valve cover gaskets........which scares me into thinking they are the same thing.....i'm hopeing i'm wrong......if its the valve cover gasket it looks like it would be right on top of the engine and fairly accessable.......or am I wrong......sure would like to save the $650 if it is something i can do myself!!!!

- valve covers are easy to remove and replace. don't pay 650 bucks for that. yes, you can use the red sealant, but I would suggest high temperature sealant, usually comes in black, it's oil resistant also. just move anything out of your way, unbolt the valve cover, clean the surfaces off the gasket will touch (cover and engine) apply gasket maker and re-attach.

- Q: emission control valve toyota camry

- emissions control valve is another name given for an exhaust gas recirculator valve(egr valve). This valve routes a sample of your cars exhaust gases back into the cylinder to be re-burned and therefore lowers emissions.The ports to this valve become clogged over time and can create performance issues

Send your message to us

API Cast Steel Check Valve 600 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords