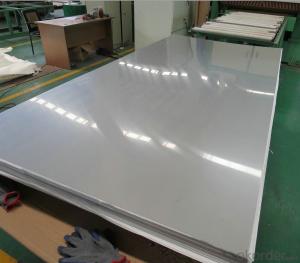

300 Series Stainless Steel

300 Series Stainless Steel Related Searches

300 Stainless Steel 301 Stainless Steel 302 Stainless Steel 305 Stainless Steel 400 Series Stainless Steel Stainless Steel 303 304 Grade Stainless Steel 330 Stainless Steel Grade 304 Stainless Steel 400 Stainless Steel Type 304 Stainless Steel Stainless Steel 316 316 Grade Stainless Steel 304l Stainless Steel Stainless Steel 316l Type 316 Stainless Steel 310 Stainless Steel 308 Stainless Steel 302 Stainless Steel Sheet 309 Stainless Steel 316l Stainless Steel 360 Stainless Steel 317 Stainless Steel Sus 304 Stainless Steel Aisi 304 Stainless Steel Sus304 Stainless Steel 403 Stainless Steel 304 Stainless Steel Tubing 304 Stainless Steel Pipe 318 Stainless Steel300 Series Stainless Steel Supplier & Manufacturer from China

The 300 Series Stainless Steel encompasses a variety of products, including 304, 316, and 310 grades, known for their excellent corrosion resistance, formability, and weldability. These properties make them ideal for a wide range of applications, such as in the construction of chemical processing equipment, food processing machinery, and various architectural components. The 300 Series Stainless Steel is particularly favored in industries where durability and resistance to harsh environments are paramount. As a leading wholesale supplier, Okorder.com offers an extensive inventory of 300 Series Stainless Steel products, catering to the needs of various industries and ensuring timely delivery and competitive pricing. This comprehensive selection allows customers to find the precise grade of stainless steel they require, whether it's for specific industrial applications or custom projects.Hot Products