Angle Bar _Steel Galvanized Angle Iron_Mild Steel Equal Angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detailed Informaion

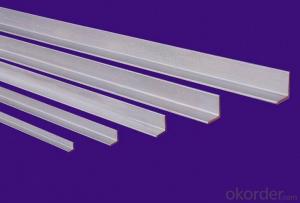

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

hot rolled equal angle steel | hot rolled unequal steel angle |

specification(mm) | specification(mm) |

20*3/4 | 26*16*3/4 |

25*3/4 | 32*20*3/4 |

30*3/4 | 40*25*3/445*28*3/4 |

36*3/4/5 | 50*32*3/4 |

40*3/4/5 | 56*36*3/4/5 |

45*3/4/5/6 | 63*40*4/5/6/7 |

50*3/4/5/6 | 70*45*4/5/6/7 |

56*3/4/5/8 | 75*50*5/6/8/10 |

63*4/5/6/8/10 | 80*50*5/6/7/8 |

70*4/5/6/7/8 | 90*56*5/6/7/8/ |

75*5/6/7/8/10 | 100*63*6/7/8/10 |

80*5/6/7/8/10 | 100*80*6/7/8/10 |

90*6/7/8/10/12 | 110*70*6/7/8/10 |

100*6/7/8/10/12/14/16 | 125*80*7/8/10/12 |

110*7/8/10/12/14 | 140*90*8/10/12/14 |

125*8/10/12/14 | 160*100*10/12/14/16 |

140*10/12/14/16 | 180*110*10/12/14/16 |

160*10/12/14/16 | 200*125*12/14/16/18 |

180*12/14/16/18 |

|

200*14/16/18/20/24 |

|

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

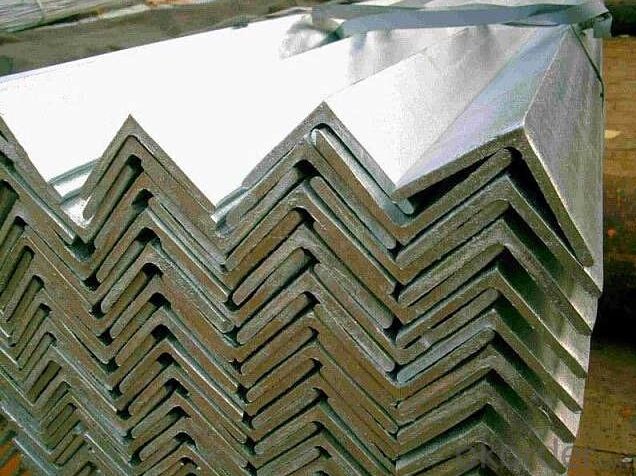

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the requirements for special steel used in construction equipment manufacturing?

- The requirements for special steel used in construction equipment manufacturing typically include high strength, durability, and resistance to wear and corrosion. Additionally, the steel should have good weldability and machinability to ensure ease of fabrication. It should also possess excellent impact resistance to withstand heavy loads and harsh working conditions.

- Q: How does special steel perform in cryogenic impact resistance?

- Special steel performs well in cryogenic impact resistance due to its high strength, toughness, and ability to retain these properties at extremely low temperatures. This makes it suitable for applications requiring exceptional resistance to fracture and deformation under cryogenic conditions.

- Q: Can special steel be used in automotive engine components?

- Automotive engine components can indeed benefit from the utilization of special steel. Also referred to as alloy steel, special steel possesses enhanced properties, including increased strength, toughness, and heat resistance. These attributes make it highly suitable for the utilization in critical engine components that endure high temperatures, stress, and wear. Within the realm of automotive engines, special steel finds application in an array of components, such as crankshafts, camshafts, connecting rods, valves, and piston rings. These components encounter extreme conditions, including elevated temperatures, pressure, and rotational forces. Special steel confers the necessary strength and durability to withstand these conditions, consequently ensuring dependable engine performance and longevity. The incorporation of special steel within automotive engine components yields several advantages. Firstly, it heightens the strength and load-carrying capacity of the components, enabling them to handle greater power and torque outputs. Secondly, special steel bolsters the fatigue resistance and durability of the components, thereby diminishing the likelihood of failure and prolonging their service life. Lastly, special steel exhibits the ability to endure the high temperatures and thermal cycling experienced within the engine, thereby averting deformation and upholding dimensional stability. On the whole, the utilization of special steel in automotive engine components assumes paramount importance in the pursuit of attaining optimal performance, reliability, and longevity. It guarantees that the engine can endure the demanding conditions under which it operates, ultimately granting a smoother and more efficient driving experience.

- Q: How does special steel contribute to the automotive noise reduction?

- Special steel contributes to automotive noise reduction in several ways. Firstly, it is durable and strong, allowing for the construction of thinner and lighter components. This reduces the overall weight of the vehicle, resulting in reduced road and engine noise. Additionally, special steel has excellent vibration-damping properties, which helps absorb and minimize noise generated by the engine, suspension, and other moving parts. The use of special steel in the design of automotive structures and panels also helps reduce noise transmission from the outside environment into the cabin, providing a quieter and more comfortable driving experience for passengers.

- Q: How does special steel contribute to improving product durability?

- Special steel contributes to improving product durability by providing enhanced strength, corrosion resistance, and wear resistance properties. Its unique composition and manufacturing processes make it highly resilient to mechanical stress, extreme temperatures, and harsh environmental conditions, thus ensuring the longevity and reliability of the products it is used in. Furthermore, special steel's exceptional properties allow for the production of lighter and more compact components, leading to increased efficiency, reduced maintenance needs, and improved overall product performance.

- Q: What are the different surface cleaning methods used for special steel?

- For special steel, there are multiple ways to clean the surface depending on specific needs and desired cleanliness level. Some commonly utilized methods are as follows: 1. Mechanical Cleaning: By employing abrasive materials or tools, such as sanding, wire brushing, or abrasive blasting, dirt, rust, and other impurities can be physically removed from the steel surface. 2. Chemical Cleaning: This technique involves the use of chemical agents to dissolve or loosen dirt, grease, oil, or rust. Different chemicals are utilized based on the type and severity of contaminants. Acid pickling, for instance, immerses the steel in an acid solution to eliminate scale and rust. 3. High-pressure Water Cleaning: High-pressure water jets forcefully eliminate dirt, grease, and other impurities from the steel surface. This method effectively removes loose particles and can be used as a preliminary step before other surface preparation techniques. 4. Ultrasonic Cleaning: By utilizing high-frequency sound waves, ultrasonic cleaning creates microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the steel surface, effectively removing hard-to-reach contaminants. 5. Electrochemical Cleaning: This method involves passing an electric current through a cleaning solution or electrolyte to aid in the removal of contaminants from the steel surface. It is particularly useful in eliminating rust and restoring the steel's appearance. 6. Thermal Cleaning: Thermal cleaning methods, such as flame cleaning or heat treatment, subject the steel to high temperatures. This process burns off organic contaminants or induces controlled oxidation, subsequently removing scale, rust, or other surface impurities. It is important to consider various factors, including the type of contaminants, steel condition, desired cleanliness level, and application requirements when choosing a surface cleaning method. Combining different methods may yield the most optimal results.

- Q: Can special steel be used in the production of consumer goods?

- Consumer goods can make use of special steel in their production. This type of steel is made up of alloys that have been specifically designed to possess distinct characteristics, such as exceptional strength, resistance to corrosion, or heat endurance. These traits enable special steel to be well-suited for a wide array of consumer goods that require longevity, robustness, or protection against wear and tear. One example of the utilization of special steel is in the manufacturing of kitchen appliances, like knives and cookware, where durability and resistance to corrosion are crucial. Additionally, consumer electronics, such as smartphones and laptops, can incorporate this steel in their casing or internal components to ensure structural integrity and safeguarding. Moreover, the automotive industry frequently relies on special steel for the creation of various consumer goods, including bicycles, motorcycles, and cars. The steel's combination of high strength and lightness makes it an ideal choice for constructing sturdy and enduring vehicle frames, engine parts, and other components. To summarize, the application of special steel in the production of consumer goods is indeed feasible due to its unique properties, which make it suitable for situations necessitating strength, durability, and protection against corrosion or wear.

- Q: What are the main applications of special steel in the defense equipment?

- Special steel is widely used in defense equipment for its exceptional properties such as high strength, durability, and resistance to extreme conditions. Some of the main applications of special steel in defense equipment include the manufacturing of armored vehicles, tanks, submarines, and naval vessels. It is also used in the production of aircraft carriers, fighter jets, and helicopters, where its strength and resistance to corrosion are crucial. Additionally, special steel is utilized in the construction of ballistic protection systems, missile components, and firearms, enhancing their performance and ensuring their reliability in critical defense operations.

- Q: What are the requirements for special steel used in aerospace defense applications?

- The requirements for special steel used in aerospace defense applications are quite stringent due to the critical nature of these applications. Some of the key requirements include: 1. High strength: Special steel used in aerospace defense applications must possess high strength to withstand extreme conditions and loads. This is essential for ensuring the structural integrity of aircraft and defense equipment. 2. Excellent corrosion resistance: Aerospace defense applications often expose the steel to harsh environments, including moisture, saltwater, and chemicals. Therefore, the steel must have exceptional corrosion resistance to prevent degradation and maintain its performance over time. 3. High temperature resistance: Special steel used in aerospace defense applications must have the ability to withstand high temperatures without losing its mechanical properties. This is crucial for components that operate in high-temperature environments, such as jet engines and rocket nozzles. 4. Fatigue resistance: The steel should be able to resist fatigue failure caused by cyclic loading, as aerospace defense applications often involve repeated stress cycles. Fatigue resistance ensures that the steel can endure long service lives without failure. 5. Lightweight: Weight reduction is a critical factor in aerospace defense applications to enhance fuel efficiency, increase payload capacity, and improve overall performance. Therefore, the special steel used should have a high strength-to-weight ratio, allowing for lighter structures without compromising strength. 6. High purity and cleanliness: The steel used in aerospace defense applications must have a high level of purity and cleanliness to minimize the presence of impurities and defects. This is crucial to ensure the reliability and longevity of the steel in demanding operational conditions. 7. Compatibility with other materials: Special steel used in aerospace defense applications should be compatible with other materials commonly used in these applications, such as aluminum alloys and composite materials. Compatibility ensures a reliable and efficient integration of different components and structures. Meeting these requirements often involves using advanced manufacturing techniques, such as vacuum melting, precise alloying, and heat treatment processes, to achieve the desired properties. Additionally, strict quality control measures, including non-destructive testing and material certification, are crucial to ensure the performance and reliability of special steel in aerospace defense applications.

- Q: What are the different methods of surface electroplating for special steel?

- There are several methods of surface electroplating for special steel, including electroless plating, electroplating by immersion, barrel plating, and rack plating. Electroless plating is a chemical process that uses a reducing agent to deposit a layer of metal onto the steel surface. Electroplating by immersion involves immersing the steel in an electrolyte bath and applying an electric current to deposit a metal coating. Barrel plating is a method where the steel parts are placed in a rotating barrel along with the plating solution, creating a tumbling action that ensures an even coating. Rack plating involves suspending the steel parts on a rack and immersing them in the plating bath. Each method has its own advantages and is chosen based on the specific requirements and characteristics of the special steel being plated.

Send your message to us

Angle Bar _Steel Galvanized Angle Iron_Mild Steel Equal Angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords