Equal-Unequal Black & Galvanized Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detailed Informaion

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

Specification | Weight | Specification | Weight |

Leg length*leg length*thickness |

| Leg length*leg length*thickness | (kg/m) |

(mm) | (kg/m) | (mm) |

|

25*25*3 | 1.124 | 90*90*8 | 10.946 |

25*25*4 | 1.459 | 90*90*10 | 13.476 |

30*30*3 | 1.373 | 100*100*6 | 9.366 |

30*30*4 | 1.786 | 100*100*7 | 10.83 |

40*40*3 | 1.852 | 100*100*8 | 12.276 |

40*40*4 | 2.422 | 100*100*10 | 15.12 |

40*40*5 | 2.976 | 100*100*12 | 17.898 |

45*45*3 | 2.088 | 110*110*7 | 11.928 |

45*45*4 | 2.736 | 110*110*8 | 13.532 |

45*45*5 | 3.369 | 110*110*10 | 16.69 |

50*50*3 | 2.332 | 110*110*12 | 19.782 |

50*50*4 | 3.059 | 125*125*8 | 15.504 |

50*50*5 | 3.77 | 125*125*10 | 19.133 |

50*50*6 | 4.465 | 125*125*12 | 22.696 |

63*63*5 | 4.822 | 125*125*14 | 26.193 |

63*63*6 | 5.721 | 140*140*10 | 21.488 |

63*63*8 | 7.469 | 140*140*12 | 25.522 |

70*70*5 | 5.397 | 140*140*14 | 29.49 |

70*70*6 | 6.406 | 160*160*10 | 24.729 |

70*70*7 | 7.398 | 160*160*12 | 29.391 |

70*70*8 | 8.373 | 160*160*14 | 33.987 |

75*75*5 | 5.818 | 160*160*16 | 38.518 |

75*75*6 | 6.905 | 180*180*12 | 33.159 |

75*75*7 | 7.976 | 180*180*14 | 38.383 |

75*75*8 | 9.03 | 180*180*16 | 43.542 |

75*75*10 | 11.089 | 180*180*18 | 48.634 |

80*80*6 | 7.376 | 200*200*14 | 42.894 |

80*80*7 | 8.525 | 200*200*16 | 48.68 |

80*80*8 | 9.658 | 200*200*18 | 54.401 |

80*80*10 | 11.874 | 200*200*20 | 60.056 |

90*90*6 | 8.35 | 200*200*24 | 71.168 |

90*90*7 | 9.656 |

|

|

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

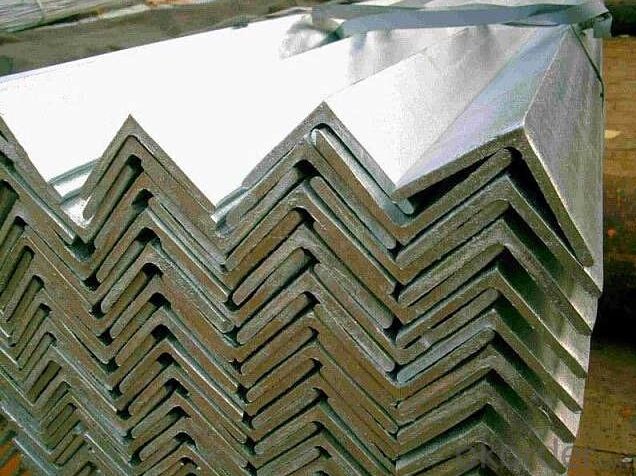

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the marine aftermarket industry?

- Special steel contributes to the marine aftermarket industry by providing high-strength and corrosion-resistant materials for various marine components and structures. This type of steel is essential for manufacturing propellers, shafts, valves, and other critical parts that ensure the performance and longevity of marine vessels. Additionally, special steel enables the construction of lighter and more fuel-efficient ships, reducing operating costs and environmental impact. Overall, the use of special steel in the marine aftermarket industry enhances safety, efficiency, and sustainability in the maritime sector.

- Q: How does special steel perform in terms of chemical resistance?

- Special steel has excellent chemical resistance properties, making it highly resistant to corrosion and oxidation. It is capable of withstanding exposure to various chemicals, acids, and corrosive environments without undergoing significant degradation. This makes special steel a reliable choice for applications that require strong resistance against chemical attack.

- Q: What are the main factors affecting the hardness of special steel?

- The main factors affecting the hardness of special steel include the composition of the steel, the heat treatment process, the grain size of the steel, and the presence of impurities or inclusions.

- Q: What are the main advantages of using special steel in the automotive industry?

- The main advantages of using special steel in the automotive industry are its high strength-to-weight ratio, improved durability and resistance to corrosion, and enhanced crashworthiness. Special steel allows for the production of lighter vehicles without compromising safety, resulting in improved fuel efficiency and reduced emissions. Additionally, its superior mechanical properties make it suitable for critical components, enhancing the overall performance and reliability of automobiles.

- Q: What are the advantages of using special steel in the marine sector?

- There are several advantages of using special steel in the marine sector. Firstly, special steel is known for its exceptional strength and durability. This is particularly important in the marine sector where structures are constantly exposed to harsh and corrosive conditions such as saltwater, extreme temperatures, and constant vibrations. Special steel has a high resistance to corrosion, making it an ideal choice for marine applications, as it can withstand the corrosive effects of seawater and prevent structural damage. Additionally, special steel offers excellent weldability, which is crucial in the construction of marine vessels and offshore structures. The ability to join steel components together seamlessly ensures the overall integrity and strength of the structure, reducing the risk of failures or accidents. Furthermore, special steel has a high fatigue strength, meaning it can withstand cyclic loading over long periods of time without experiencing failure. This is particularly important in the marine sector where structures are subjected to constant dynamic loads, such as waves and wind forces. The fatigue resistance of special steel ensures the longevity and reliability of marine structures, reducing maintenance costs and improving safety. Moreover, special steel offers design flexibility and versatility. It can be easily shaped and molded into various complex forms, allowing for innovative and efficient designs in marine structures and vessels. This flexibility also enables the optimization of weight, which is crucial in the marine sector to improve fuel efficiency and reduce emissions. Lastly, special steel is readily available and cost-effective. With advancements in manufacturing processes and technologies, special steel production has become more efficient and cost-effective, making it a viable choice for the marine sector. Its availability and affordability make it a preferred material for various marine applications. In conclusion, the advantages of using special steel in the marine sector include its exceptional strength and durability, resistance to corrosion, excellent weldability, high fatigue strength, design flexibility, and cost-effectiveness. These properties make special steel a reliable and efficient material for constructing marine structures, ensuring their longevity, safety, and operational efficiency.

- Q: How is weathering steel used in outdoor structures?

- Weathering steel is commonly used in outdoor structures due to its unique ability to form a protective rust-like coating, which not only enhances its aesthetic appeal but also acts as a barrier against further corrosion. This steel is often utilized in bridges, sculptures, buildings, and other architectural elements, providing durability, strength, and a distinct rust-colored appearance that blends harmoniously with the natural surroundings.

- Q: What are the different methods of improving the fatigue resistance of special steel?

- There are several methods that can be employed to improve the fatigue resistance of special steel. These methods aim to enhance the material's ability to withstand cyclic loading and prevent fatigue failure. 1. Heat Treatment: One common method is to subject the special steel to heat treatment processes such as annealing, normalizing, or quenching and tempering. These treatments can alter the microstructure of the steel, improving its strength, toughness, and fatigue resistance. 2. Surface Treatment: Applying surface treatments like shot peening or surface hardening can significantly enhance the fatigue resistance of special steel. Shot peening involves bombarding the surface with small, high-velocity steel shots, inducing compressive stresses that counteract the tensile stresses during cyclic loading. Surface hardening techniques, such as carburizing or nitriding, create a hardened layer on the surface of the steel, which increases its resistance to fatigue. 3. Alloying: Modifying the composition of the special steel by adding specific alloying elements can greatly enhance its fatigue resistance. For example, adding elements like chromium, molybdenum, or nickel can improve the material's strength, ductility, and resistance to fatigue crack initiation and propagation. 4. Grain Refinement: Refining the grain structure of the special steel can lead to improved fatigue resistance. Techniques like severe plastic deformation or grain refinement through thermomechanical processing can promote the formation of finer grains, which reduce the susceptibility to fatigue crack initiation and propagation. 5. Microstructural Control: Optimizing the microstructure of the special steel can be achieved through techniques such as controlled rolling, controlled cooling, or precipitation hardening. These methods aim to achieve a desirable microstructural balance, such as fine dispersion of precipitates or a refined grain structure, which improves the material's fatigue resistance. 6. Residual Stress Control: Managing residual stresses within the special steel can help improve its fatigue resistance. Techniques like stress relieving or balancing residual stresses through appropriate heat treatment can reduce the likelihood of fatigue crack initiation and propagation. It is important to note that the specific method or combination of methods employed to enhance fatigue resistance will depend on the specific alloy and application requirements. Additionally, thorough testing and evaluation should be conducted to ensure the effectiveness of these methods in improving the fatigue resistance of special steel.

- Q: What are the different methods of surface protection for special steel?

- Different methods of surface protection for special steel offer unique benefits and are suitable for specific applications. Some commonly used methods are: 1. Galvanization: Zinc coating is applied to the steel, providing excellent corrosion resistance. Hot-dip galvanization or electroplating can be used depending on the requirements. 2. Paint coating: A paint coating is applied to protect the steel from corrosion and environmental factors. The paint acts as a barrier, preventing rust and damage. 3. Powder coating: Dry powder is applied to the steel surface and heated to create a protective layer. This method offers excellent resistance to corrosion, chemicals, and abrasion, making it ideal for harsh conditions. 4. Electroplating: A layer of metal is deposited onto the steel surface through an electrochemical process. This enhances corrosion resistance and may provide additional benefits such as increased hardness or improved aesthetics. 5. Thermal spraying: Material like zinc or aluminum is melted or heated and sprayed onto the steel surface to form a protective coating. Thermal spraying offers excellent corrosion protection and can be used for surface repairs. 6. Ceramic coating: Ceramic coatings are highly resistant to corrosion, abrasion, and high temperatures. They are commonly used in extreme conditions such as the aerospace or automotive industries. 7. Passivation: Chemical process removes free iron and contaminants from the surface of stainless steel. This improves corrosion resistance by forming a passive oxide layer. Choosing the appropriate surface protection method depends on the specific requirements of the steel and its application. Factors such as desired corrosion resistance level, environmental conditions, and desired lifespan should be considered when selecting a method.

- Q: Does special steel have any magnetic properties?

- Yes, special steel can have magnetic properties, depending on its composition and treatment. Steel is primarily composed of iron, and iron is a ferromagnetic material, meaning it can be magnetized. However, the presence of other elements such as nickel, cobalt, and certain alloys can affect the magnetic properties of steel. For instance, stainless steel, which contains chromium and nickel, is generally non-magnetic or only weakly magnetic. On the other hand, materials like tool steel or high-speed steel can exhibit stronger magnetic properties due to their composition and heat treatment. Therefore, it is important to consider the specific type of special steel and its alloying elements when determining its magnetic properties.

- Q: How does special steel contribute to the renewable energy storage?

- Special steel plays a crucial role in renewable energy storage by enabling the construction of durable and efficient energy storage systems. It is used in the manufacturing of batteries, fuel cells, and other components, providing strength, corrosion resistance, and thermal stability. The high-quality properties of special steel help enhance the performance and longevity of renewable energy storage technologies, ensuring their reliability and contributing to the overall sustainability and viability of the renewable energy sector.

Send your message to us

Equal-Unequal Black & Galvanized Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords