Miniature Ball Bearings Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Miniature Ball Bearings Steel

1. Dimensional sizes: Thickness: 14~100mm.Length:3000~5800mm,Diameter :14-500mm

2.Chemical composition: C=0.96~1.05,Si=0.15~0.35,Mn=0.25~0.45,Cr=1.4~1.65,

P≤0.025,S≤0.025,Ni≤0.22,Cu≤0.20,Mo≤0.08

3. Grade: SAE51200/ GCr15 / 100cr6

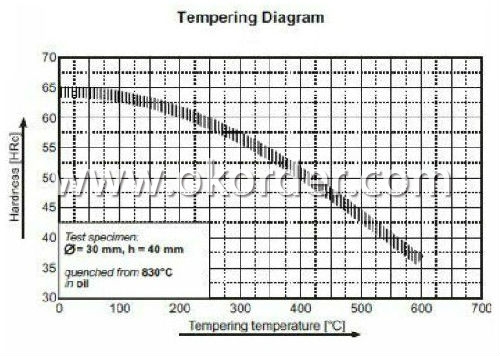

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Payment terms: 20% deposit, balance against L/C at sight or T/T.

Usage & Applications of Miniature Ball Bearings Steel

Miniature ball bearings are machinery components, which comprise an outer ring, inner ring, balls, retainers, shields and snap rings. High quality through hardened bearing steel improves reliability. High grade balls have improved roundness and finish to reduce vibration and noise. Super finished raceways to reduce friction, vibration and noise resulting in increased bearing life and reduced maintenance cost. Proven seal solutions effectively retain lubricant and exclude contamination from moisture, dust, and dirt which extends bearing life and reduces maintenance cost. Premium grease reduces noise, vibration and meets high temperature application requirements which extend bearing life. Bearings available 100% noise tested on state-of the art equipment to meet Electric Motor OEM low noise expectations. Product tolerances exceed bearing industry standards to allow for global interchangeability.

Packaging & Delivery of Miniature Ball Bearings Steel

10 pieces in one plastic tube, 10 tubes in one paper box or as customer required

Delivery time: 20 days after order confirmed.

Samples Policy: please arrange the sample cost and freight or freight collected. We will reduce this part expense from the total value of our first order.

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

- Q: What are the different forging techniques used for special steel?

- There are several forging techniques used for special steel, including open die forging, closed die forging, and ring rolling. Open die forging involves shaping the steel between flat dies, allowing for flexibility in the size and shape of the final product. Closed die forging, on the other hand, uses shaped dies to shape the steel into a specific form. Ring rolling is a technique used to produce seamless rings by rolling a heated steel billet between two rotating rolls to achieve the desired shape. These techniques ensure the production of high-quality, customized special steel products for various applications.

- Q: How does special steel perform in high-pressure applications?

- Special steel performs exceptionally well in high-pressure applications. This type of steel is specifically designed to withstand extreme pressure conditions, making it an ideal choice for industries that require reliable and durable materials for their operations. One of the key characteristics of special steel is its high tensile strength, which allows it to handle immense pressure without deformation or failure. This strength is achieved through alloying elements and heat treatment processes that enhance the steel's structural integrity. As a result, special steel can withstand the intense forces exerted on it in high-pressure environments, ensuring the safety and efficiency of the equipment or structures it is used in. Furthermore, special steel exhibits excellent resistance to corrosion and oxidation, further enhancing its suitability for high-pressure applications. This resistance helps maintain the structural integrity of the steel, preventing any weakening or degradation that could compromise its performance under pressure. Additionally, special steel's resistance to corrosion ensures that it can withstand harsh environments, such as those found in oil and gas extraction, chemical processing, or power generation industries. Another advantage of special steel in high-pressure applications is its ability to retain its mechanical properties even at elevated temperatures. This property is crucial in industries where high temperatures are involved, such as aerospace, nuclear power, or steam generation. The steel's high-temperature strength and stability enable it to withstand the combination of high pressure and elevated temperatures, ensuring reliable performance and long-term durability. In summary, special steel is an excellent choice for high-pressure applications due to its high tensile strength, resistance to corrosion and oxidation, as well as its ability to maintain its mechanical properties at elevated temperatures. Its exceptional performance in these demanding conditions makes it a reliable and durable material for industries that operate under high-pressure environments.

- Q: How does special steel contribute to the textile industry?

- Special steel contributes to the textile industry by providing high-strength and durable components for textile machinery, such as looms, knitting machines, and textile processing equipment. The use of special steel in these machines ensures improved performance, precision, and longevity, thereby enhancing productivity and efficiency in textile manufacturing processes. Additionally, special steel's resistance to corrosion and wear helps maintain the quality and reliability of textile machinery, minimizing downtime and maintenance costs for manufacturers.

- Q: What are the main applications of special steel?

- Special steel has a wide range of applications in various industries such as automotive, aerospace, construction, energy, and manufacturing. It is commonly used for the production of high-performance components, tools, and machinery parts that require exceptional strength, durability, and resistance to corrosion and heat. Additionally, special steel is utilized in the production of surgical instruments, cutlery, and various consumer goods that require high-quality materials to ensure reliability and longevity.

- Q: What are the properties of magnetic steel?

- Magnetic steel is characterized by its ability to attract and hold a magnetic field. It is typically a hard and strong material, making it suitable for various applications such as in the production of magnets, electrical transformers, and motors. Magnetic steel also has high permeability, allowing it to efficiently conduct magnetic flux. Additionally, it exhibits good resistance to corrosion, which helps maintain its magnetic properties over time.

- Q: How does special steel withstand extreme temperatures?

- Special steel is designed to withstand extreme temperatures due to its unique composition and manufacturing process. It contains a higher percentage of alloying elements, such as chromium, nickel, and molybdenum, which enhance its heat resistance properties. These alloys form a protective layer on the surface of the steel, preventing oxidation and corrosion at high temperatures. Additionally, special steel undergoes specific heat treatment methods, such as quenching and tempering, which further enhance its ability to withstand extreme temperatures without losing its strength and structural integrity.

- Q: Can special steel be used in the manufacturing industry?

- Yes, special steel can be used in the manufacturing industry. Special steel refers to various high-quality and specialized alloys that possess unique properties, such as high strength, corrosion resistance, heat resistance, and wear resistance. These properties make special steel suitable for a wide range of applications in the manufacturing industry, including the production of machinery, tools, automotive components, aerospace parts, and construction materials.

- Q: How does special steel resist thermal fatigue?

- Special steel resists thermal fatigue due to its unique composition and structure. It is designed to have excellent thermal conductivity, allowing it to quickly dissipate heat and prevent the formation of thermal gradients within the material. This reduces the likelihood of cracking, deformation, or failure when exposed to rapid and repeated temperature fluctuations. Additionally, special steel undergoes specific heat treatment processes that enhance its resistance to thermal fatigue by improving its strength, toughness, and ability to withstand thermal shocks.

- Q: How is special steel protected against corrosion?

- Special steel is protected against corrosion through various methods such as applying a protective coating, using corrosion-resistant alloys, or implementing techniques like passivation and electroplating.

- Q: What are the different methods for nitriding special steel?

- There are several methods for nitriding special steel, including gas nitriding, salt bath nitriding, plasma nitriding, and ion nitriding.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

Miniature Ball Bearings Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords