SAE 1035 Carbon Steel Round Bar CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SAE 1035 Carbon Steel Round Bar

Product Description:

1. Sizes: Diameter: 16mm-300mm; Length: 6m, 9m, 12m

2. Grade: 35#, SAE1035, S35C, C35

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled, forged, cold rolled

Chemical Composition:

| C | Si | Mn | P | S | Ni | Cr | Cu |

| 0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packing and Delivery:

Packing in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: Approx.45 days

Usage and Applications

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some especial material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 35# | |||

200-500mm | 35# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

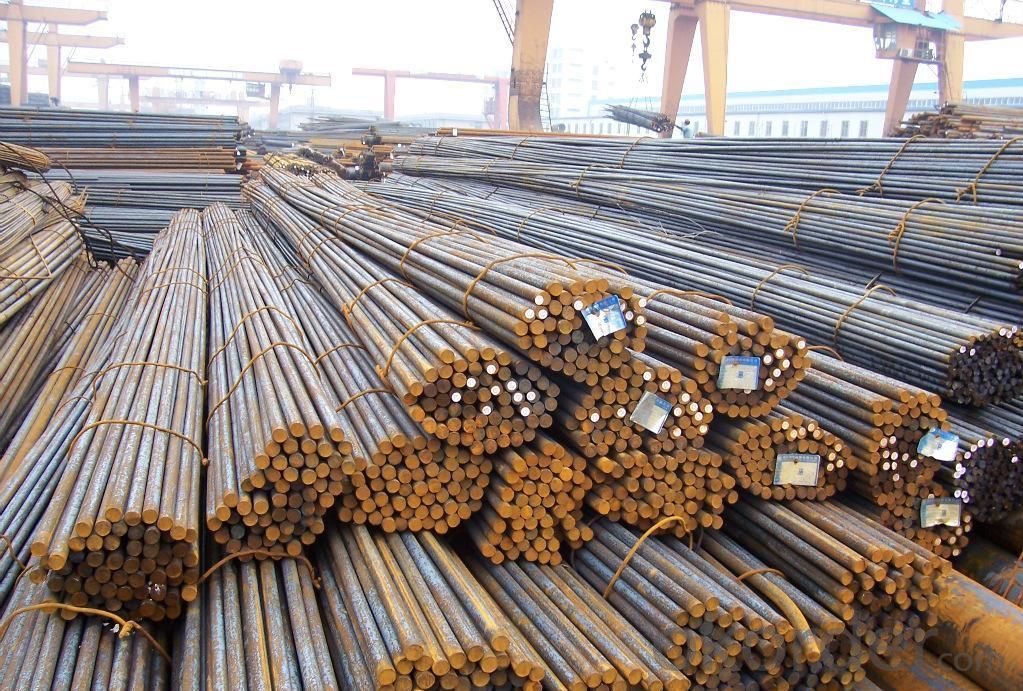

Main product pictures:

- Q: What are the main factors affecting the wear resistance of special steel?

- The main factors affecting the wear resistance of special steel include the composition of the steel, the hardness and microstructure of the steel, the presence of carbides or other hardening elements, the surface finish and treatment of the steel, and the operating conditions in which the steel is used.

- Q: What is the difference between general steel and special steel?

- Special steel: it is an important symbol to measure whether a country can become a steel power. It is the main steel used in most industries such as machinery, automobile, military industry, chemical industry, household electrical appliance, shipping, traffic, railway and new industries. China's special steel industry is responsible for the special steel products needed by the key industries such as defense industry, high and new technology industry and machinery and automobile industry. China manufacturing growth to provide a space for the development of domestic special steel, sustained and rapid development of manufacturing industry, especially in machinery, automobile, machinery, shipbuilding and other industries, the strong demand of special steel, become the direct impetus to support excellent steel market.

- Q: What are the different methods for improving the creep resistance of special steel?

- Several methods exist to enhance the creep resistance of special steel. One commonly employed technique involves alloying. By incorporating specific alloying elements like chromium, molybdenum, and vanadium, the steel's creep resistance can be significantly improved. These alloying elements create stable carbides or nitrides that serve as obstacles to dislocation movement, thereby reducing the rate of creep deformation. Heat treatment represents another effective approach. By subjecting the steel to carefully controlled heating and cooling processes, the microstructure can be refined to enhance its creep resistance. Techniques such as quenching and tempering aid in the formation of a fine-grained structure, which in turn increases the steel's strength and resistance to creep. Surface modification offers an alternative means of improving creep resistance. Nitriding and carburizing techniques can be utilized to introduce nitrogen or carbon into the steel's surface layer, creating a hardened layer that enhances creep resistance. Moreover, grain size control can be achieved through methods like grain boundary engineering or severe plastic deformation. By refining the grain structure, the movement of dislocations within the material is impeded, resulting in improved creep resistance. Lastly, the application of coatings can also bolster the creep resistance of special steel. Coatings such as ceramic or metallic coatings provide a protective layer that hampers the diffusion of impurities and slows down the creep rate. To summarize, the improvement of creep resistance in special steel can be accomplished through various techniques, including alloying, heat treatment, surface modification, grain size control, and the use of coatings. These methods aim to fortify the steel's microstructure, hinder dislocation movement, and establish protective barriers against creep deformation.

- Q: How is special steel produced?

- Special steel is produced through a meticulous process known as alloying, where different metals are combined with iron to enhance its properties. The alloying elements are carefully selected and added to molten iron, followed by precise temperature control and cooling to form the desired steel composition. This process ensures that special steel possesses superior strength, hardness, corrosion resistance, and other unique characteristics required for specialized applications.

- Q: Can special steel be used in the production of jewelry?

- Indeed, it is possible to utilize special steel in the fabrication of jewelry. While precious metals such as gold, silver, and platinum are frequently employed in the art of jewelry making, there is an emerging inclination towards incorporating unconventional materials like special steel. The distinctive attributes of special steel, namely its durability, strength, and resistance to corrosion, allow for the creation of exquisite and intricate designs that cater to a contemporary and bold aesthetic. Moreover, special steel jewelry often presents a more economical alternative to traditional precious metal jewelry, rendering it a favored choice for individuals seeking a distinctive and budget-conscious option. Nevertheless, it is crucial to bear in mind that special steel jewelry necessitates proper care and maintenance to prevent tarnishing and scratching.

- Q: What are the different methods of preventing hydrogen embrittlement in special steel?

- There are several methods that can be employed to prevent hydrogen embrittlement in special steel. 1. Proper material selection: Choosing the right type of steel with a lower susceptibility to hydrogen embrittlement can be an effective preventive measure. Steels with high strength and hardness are generally more susceptible to embrittlement, so opting for steels with lower alloy content or different composition can be beneficial. 2. Controlled heat treatment: Proper heat treatment processes can help reduce the risk of hydrogen embrittlement. Tempering and annealing at specific temperatures can relieve internal stresses and minimize the impact of hydrogen absorption. 3. Hydrogen mitigation techniques: Various techniques can be utilized to prevent or reduce the amount of hydrogen in the steel. These include preheating the steel before exposure to hydrogen, utilizing desorption methods such as vacuum annealing to remove trapped hydrogen, and employing hydrogen scavenger coatings or inhibitors that capture or neutralize the hydrogen. 4. Stress reduction: High levels of stress can increase the likelihood of hydrogen embrittlement. Implementing stress relief techniques such as shot peening or stress-relieving heat treatments can help reduce the potential for embrittlement. 5. Proper handling and storage: Hydrogen embrittlement can also occur during the manufacturing, handling, or storage stages. It is essential to ensure that the steel is protected from exposure to hydrogen-rich environments, such as during cleaning or pickling processes. Proper packaging and storage techniques, including the use of dry environments or protective coatings, can also help prevent hydrogen absorption. 6. Maintenance and inspection: Regular inspection and maintenance of the steel components can help identify any signs of hydrogen embrittlement at an early stage. This allows for timely repairs or replacements to prevent catastrophic failures. It is important to note that the specific method or combination of methods employed to prevent hydrogen embrittlement may vary depending on the specific application, the type of steel, and the environmental conditions it will be exposed to. Therefore, it is crucial to consult with experts and adhere to industry standards and guidelines to ensure effective prevention of hydrogen embrittlement in special steel.

- Q: What are the main advantages of using special steel in the defense industry?

- The main advantages of using special steel in the defense industry are its exceptional strength, durability, and resistance to extreme conditions. Special steel can withstand high impact and provide superior protection against ballistic threats, making it ideal for armored vehicles, tanks, and military aircraft. Additionally, its corrosion resistance ensures longevity and reduces maintenance requirements. Special steel also offers versatility in terms of design and customization, allowing for the development of advanced weaponry and equipment.

- Q: What are the common alloying elements in special steel?

- The common alloying elements in special steel are chromium, manganese, molybdenum, nickel, and vanadium.

- Q: What are the advantages of using special steel in specific applications?

- Using special steel in specific applications brings several advantages. Firstly, special steel outperforms regular steel in terms of strength and durability. It possesses higher tensile strength and better resistance to wear and tear, making it ideal for demanding industries like construction, automotive, and aerospace. This ensures that components made from special steel can withstand heavy loads, extreme temperatures, and harsh operating conditions without any deformation or failure. Secondly, special steel demonstrates exceptional corrosion resistance. It can effectively combat the detrimental effects of moisture, chemicals, and other corrosive elements, making it suitable for marine environments, chemical processing plants, and offshore structures. Special steel maintains its structural stability and integrity even when exposed to aggressive substances, which ultimately prolongs the lifespan of equipment and reduces maintenance costs. Another advantage of special steel lies in its versatility. It can be easily customized and tailored to meet the specific requirements of various applications. Special steel can be engineered to possess specific mechanical properties, such as hardness, toughness, or flexibility, depending on the desired application. This enables greater adaptability and empowers designers and engineers to create components that are optimized for their intended use. Furthermore, special steel often exhibits excellent heat resistance capabilities. It can endure high temperatures without sacrificing its mechanical properties, making it suitable for applications involving extreme heat, such as industrial furnaces, turbines, and engines. The steel's ability to withstand heat ensures that it retains its strength and shape, minimizing the risk of deformation or failure under elevated temperatures. Lastly, special steel offers superior machinability and weldability. It can be easily shaped, cut, and welded into intricate shapes and structures, facilitating efficient manufacturing processes and reducing production costs. Special steel's machinability also guarantees precise and accurate fabrication, resulting in high-quality components that meet stringent industry standards. In conclusion, special steel provides enhanced strength, durability, corrosion resistance, versatility, heat resistance, and excellent machinability, making it the preferred choice for various industries where reliability, performance, and longevity are crucial.

- Q: How does special steel contribute to the automotive parts industry?

- Enhanced strength, durability, and performance are crucial attributes that special steel brings to the automotive parts industry. This unique material plays a pivotal role in improving the overall safety, reliability, and efficiency of vehicles. One of the primary benefits of special steel in the automotive parts industry is its ability to withstand extreme conditions, high temperatures, and pressures. This exceptional characteristic makes it perfect for manufacturing vital engine parts like crankshafts, camshafts, and connecting rods, which endure intense mechanical stress and heat. By utilizing special steel, these critical components can withstand the demanding conditions of combustion engines, resulting in enhanced engine performance and longevity. Another significant advantage of special steel is its resistance to corrosion. Automotive parts are exposed to various corrosive elements such as moisture, chemicals, and road salt. With the use of special steel, manufacturers can produce corrosion-resistant parts like exhaust systems, suspension components, and brake rotors, which play a crucial role in maintaining the structural integrity and safety of vehicles over time. Furthermore, special steel offers exceptional formability and weldability, enabling the production of complex automotive parts with precision and ease. This versatility allows manufacturers to create lightweight yet robust components like chassis, body panels, and suspension arms. These components contribute to fuel efficiency, handling, and overall vehicle performance. Additionally, the high tensile strength and toughness of special steel contribute to the safety of vehicles by ensuring the structural integrity of safety-critical parts like steering columns, seat frames, and roll bars. These components play a vital role in protecting occupants during accidents and collisions, making special steel an indispensable material for enhancing overall vehicle safety. In conclusion, the unique properties and characteristics of special steel have a significant impact on the automotive parts industry. Its strength, durability, corrosion resistance, formability, and weldability make it an ideal material for manufacturing critical components in automobiles. By incorporating special steel into various parts, vehicles can achieve improved performance, safety, and reliability while meeting the demands of modern automotive standards.

Send your message to us

SAE 1035 Carbon Steel Round Bar CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords