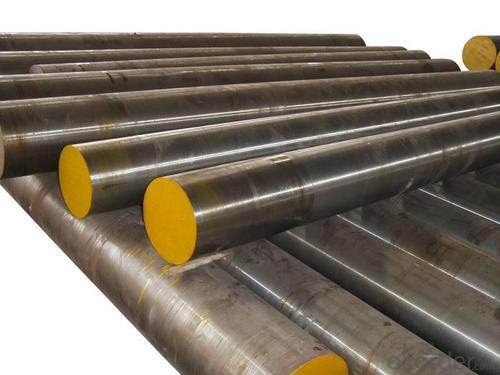

Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction:

-Material: 60Si2CrA

-Standard: GB/T 1222-1984

-Type: Spring Steel

Corresponding Steel Grade for Reference:

CHN, GB | JPN, JIS | GER, DIN | GBR, BS |

60Si2CrA | SWOSC-V | 67SiCr5 | 685H57 |

USA, AISI/SAE/ASTM | ISO | ||

9254 | 55SiCr63 |

Chemical Composition:

C | Si | Mn | S |

0.52~0.60 | 1.5~2.00 | 0.60~0.90 | ≤0.035 |

P | Cr | Ni | Cu |

≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1274(130)

-Yield Strength σs (MPa): ≥1176(120)

-Elongation δ10(%): ≥6

-Percentage reduction of area: ψ (%): ≥30

-Hardness:

1, Hot rolled, ≤302HB

2, Cold drawn + Heat treatment: ≤321HB

-Norm of heat treatment: quenching 870℃±20℃

-Micro structure: Tempered troostite.

Usage/Applications of Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction:

-Compared with Si-Mn spring steel under the similar condition of plasticity, 60Si2CrA have higher tensile strength, yield strength and hardenability.

-60Si2CrA is applied for producing springs with working temperature below 300~500℃. This type of spring can bear high stress, for example, governor spring, turbine steam seal spring, etc…

Packaging & Delivery of Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons

-Marks: there are two types of marks. One is tag mark, for showing customers the specifications of products, company name and logo and other information required by customers. Other one is color marks. They are used to make the products more evident so that it’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products are usually transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the properties of nitrogen alloyed steel?

- Nitrogen alloyed steel typically exhibits improved strength, hardness, and corrosion resistance compared to regular carbon steel. It also has excellent wear resistance and may have enhanced toughness. Additionally, nitrogen alloying can improve the steel's ability to retain its properties at high temperatures, making it suitable for applications in challenging environments.

- Q: Can special steel be used in the oil refinery industry?

- Yes, special steel can be used in the oil refinery industry. Special steel alloys such as stainless steel, duplex stainless steel, and nickel-based alloys have excellent corrosion resistance properties, high temperature strength, and resistance to cracking, making them ideal for various applications in oil refineries. These materials can be used for equipment such as pipes, valves, heat exchangers, and storage tanks, ensuring the safe and efficient operation of oil refineries.

- Q: How is special steel used in the production of conveyor belts?

- Special steel is used in the production of conveyor belts primarily for their strength and durability. It is commonly used in the construction of belt pulleys and rollers, which are essential components of conveyor systems. The special steel used in these parts ensures that they can withstand heavy loads, resist wear and tear, and maintain their shape and functionality over long periods of use.

- Q: What are the different methods of surface carburizing for special steel?

- Some of the different methods of surface carburizing for special steel include pack carburizing, gas carburizing, liquid carburizing, and plasma carburizing.

- Q: What are the different certifications available for special steel?

- There are several certifications available for special steel, depending on the specific industry and application. Some of the commonly recognized certifications include: 1. ISO 9001: This certification ensures that the special steel manufacturer has implemented and maintained a quality management system that complies with international standards. It demonstrates the company's commitment to consistently providing products that meet customer requirements. 2. ISO 14001: This certification focuses on environmental management and ensures that the special steel manufacturer has implemented environmentally friendly practices in their operations. It demonstrates the company's commitment to reducing their environmental impact. 3. ASME (American Society of Mechanical Engineers) certifications: ASME offers various certifications for special steel used in pressure vessels, boilers, and other applications. These certifications ensure that the special steel meets specific quality and safety standards required by the industry. 4. PED (Pressure Equipment Directive): This certification is required for special steel used in pressure equipment in the European Union. It ensures that the steel meets specific safety and quality requirements. 5. NACE (National Association of Corrosion Engineers) certifications: NACE offers certifications for special steel used in corrosive environments. These certifications ensure that the steel has the necessary resistance against corrosion and can withstand harsh conditions. 6. API (American Petroleum Institute) certifications: API offers certifications for special steel used in the oil and gas industry. These certifications ensure that the steel meets specific quality and performance standards required for various applications in the industry. 7. ASTM (American Society for Testing and Materials) certifications: ASTM offers various certifications for special steel based on specific standards and specifications. These certifications ensure that the steel meets the required mechanical properties, chemical composition, and other criteria. It is important for manufacturers, suppliers, and end-users to consider these certifications when selecting special steel for their specific applications. These certifications provide assurance and confidence in the quality, safety, and performance of the special steel products.

- Q: What are the main factors affecting the impact toughness of special steel?

- The impact toughness of special steel, or any material for that matter, is influenced by various factors. Some of the main factors affecting the impact toughness of special steel are: 1. Composition: The chemical composition of the steel plays a significant role in determining its impact toughness. Elements such as carbon, manganese, silicon, nickel, and molybdenum can be added to enhance the toughness of the steel. Higher carbon content generally improves hardness but reduces toughness, while alloying elements like nickel and molybdenum can enhance toughness. 2. Heat treatment: The heat treatment process, including processes like quenching and tempering, can significantly affect the impact toughness of special steel. Proper heat treatment can refine the microstructure of the steel, making it more resistant to fractures and increasing its toughness. 3. Microstructure: The microstructure of the steel, including the size, shape, and distribution of its grains, greatly impacts its toughness. Fine-grained steels generally exhibit better toughness compared to coarse-grained ones. The presence of certain phases, such as martensite or bainite, can also affect the impact toughness. 4. Inclusions: The presence of non-metallic inclusions, such as sulfides, oxides, or carbides, in the steel can act as stress concentration points and reduce its impact toughness. High-quality special steels often undergo processes like vacuum degassing or electroslag remelting to minimize the presence of these inclusions. 5. Processing conditions: The manufacturing processes used to produce special steel can influence its impact toughness. Factors such as forging, rolling, or extrusion conditions, as well as the cooling rate during solidification, can affect the microstructure and, consequently, the toughness of the steel. 6. Temperature: The impact toughness of special steel also varies with temperature. Some steels exhibit good toughness at low temperatures, while others may have better performance at higher temperatures. The temperature at which the steel is used or tested is an important factor to consider when evaluating its impact toughness. It is worth noting that the impact toughness of special steel is often determined using standardized tests, such as the Charpy or Izod test, which involve subjecting a notched specimen to impact loading. These tests provide valuable information on the material's ability to absorb energy and resist fracture under impact conditions.

- Q: How does special steel contribute to reducing greenhouse gas emissions?

- Special steel can contribute to reducing greenhouse gas emissions in several ways. Firstly, it can be used in the manufacturing of more energy-efficient vehicles, which emit lower levels of carbon dioxide during operation. Additionally, special steel can be utilized in the production of renewable energy infrastructure, such as wind turbines and solar panels, which helps reduce reliance on fossil fuels. Furthermore, special steel is often employed in the construction of energy-efficient buildings, which require less energy for heating and cooling, thus lowering overall emissions. Overall, the use of special steel in various applications plays a significant role in the reduction of greenhouse gas emissions and the transition to a more sustainable future.

- Q: What are the different methods of hardening special steel?

- There exist various techniques for strengthening special steel, each possessing its own merits and suitable applications. 1. Quenching: A widely employed approach for steel hardening, it entails heating the steel to a critical temperature and rapidly cooling it in a quenching medium such as oil, water, or air. This rapid cooling prompts the formation of a martensitic structure, rendering the steel harder but more brittle compared to its original state. 2. Tempering: Following quenching, steel is often subjected to tempering to decrease brittleness and enhance toughness. This process involves reheating the hardened steel to a specific temperature and maintaining it at that temperature for a predetermined duration. By doing so, internal stresses are reduced, and the overall mechanical properties of the steel are improved. 3. Case hardening: Employed to augment the hardness of the outer layer of steel while preserving a tough and ductile core, case hardening involves introducing carbon or nitrogen into the steel's surface through methods like carburizing or nitriding. This results in the creation of a hardened surface layer while retaining the desired properties within the core. 4. Induction hardening: Particularly useful for localized hardening of specific regions within a component, this technique employs an electromagnetic field to solely heat the desired area of the steel, followed by rapid quenching. Induction hardening allows precise control over the hardened region while maintaining desired properties in the remainder of the component. 5. Cryogenic treatment: Involving subjecting hardened steel to extremely low temperatures, often below -150°C (-238°F), this process further refines the steel's microstructure, enhancing its hardness, wear resistance, and dimensional stability. 6. Flame hardening: This method entails heating the steel's surface using a high-temperature flame and subsequently quenching it. Flame hardening is typically employed for large components or specific areas requiring localized hardening. Selecting the appropriate method is crucial and dependent on the steel's specific requirements and intended application. Factors such as desired hardness, toughness, wear resistance, and dimensional stability play a pivotal role in method selection.

- Q: How is HSLA steel used in the construction industry?

- HSLA (High-Strength Low-Alloy) steel is commonly used in the construction industry for various applications. It offers increased strength, durability, and better resistance to corrosion compared to conventional carbon steel. HSLA steel is used in the construction of bridges, buildings, pipelines, and other structures where high strength and reliability are required. Additionally, it can be found in structural components like beams, columns, and trusses, as well as in reinforcement bars and plates. Overall, HSLA steel plays a crucial role in enhancing the safety, longevity, and overall performance of construction projects.

- Q: Can special steel be welded?

- Yes, special steel can be welded. However, the specific welding process and techniques may vary depending on the type of special steel being used. It is important to have a good understanding of the particular steel's composition and properties to ensure proper welding procedures are followed.

Send your message to us

Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords