Chrome Price Q235 CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| GRADE | SIZE | APPLICATION |

| Q235 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

| Q235 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.14-0.22 | 0.15-0.30 | 0.40-0.65 | 0.040% Max | 0.05Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

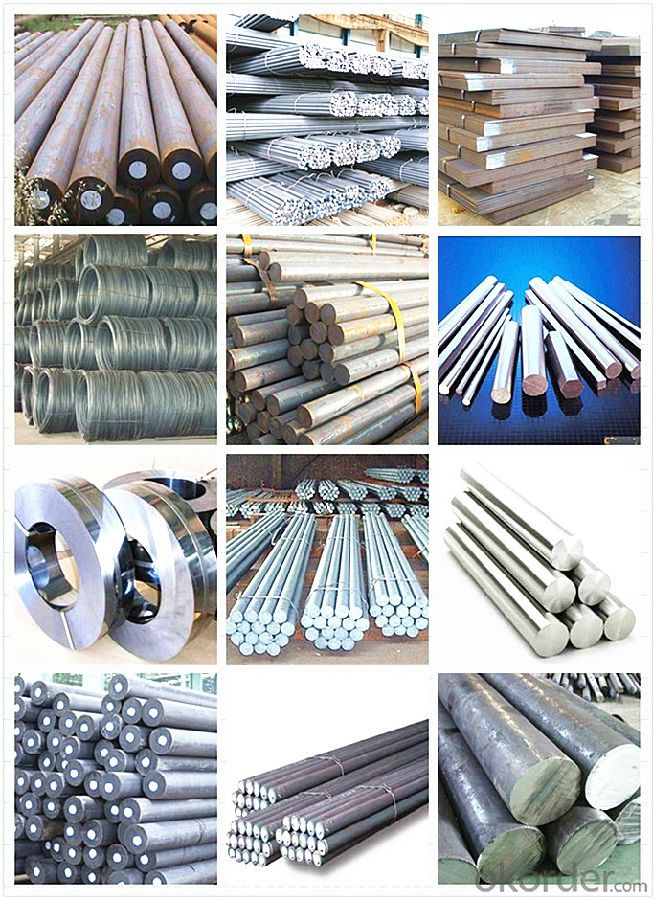

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different applications of tool special steel?

- Tool special steel is a versatile material that finds applications in various industries due to its unique properties. Some of the different applications of tool special steel include: 1. Cutting Tools: Tool special steel is widely used in the manufacturing of cutting tools such as drills, saw blades, milling cutters, and lathe tools. Its high hardness, wear resistance, and toughness make it ideal for these applications, ensuring long tool life and excellent cutting performance. 2. Dies and Molds: Tool special steel is also extensively used in the production of dies and molds for metalworking and plastic injection molding processes. Its ability to withstand high temperatures, resist wear and deformation, and maintain dimensional stability make it suitable for these demanding applications. 3. Automotive Industry: Tool special steel is employed in the automotive industry for various components such as crankshafts, gears, camshafts, and engine valves. Its excellent strength, fatigue resistance, and heat resistance qualities contribute to the overall durability and performance of automotive parts. 4. Aerospace Industry: Tool special steel is utilized in the aerospace industry for applications such as turbine blades, aircraft engine components, landing gears, and structural parts. Its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressure make it an ideal choice for these critical applications. 5. Construction and Mining: Tool special steel is used in the construction and mining sectors for equipment such as excavator buckets, rock drills, bulldozer blades, and drilling bits. Its high hardness, toughness, and resistance to abrasion enable these tools to withstand the harsh conditions encountered in these industries. 6. Tooling Industry: As the name suggests, tool special steel is extensively used in the tooling industry for the manufacture of various types of tools and equipment. Whether it is hand tools, power tools, or precision instruments, tool special steel is employed due to its exceptional strength, hardness, and resistance to wear and deformation. 7. Medical Industry: Tool special steel is also utilized in the medical field for the production of surgical instruments, orthopedic implants, and dental tools. Its biocompatibility, corrosion resistance, and ability to be sterilized make it suitable for these critical applications. These are just a few examples of the numerous applications of tool special steel. Its unique properties make it a valuable material in various industries where durability, strength, and precision are essential requirements.

- Q: How does special steel perform in electrical conductivity applications?

- Special steel, also known as stainless steel, offers excellent electrical conductivity properties in various applications. It is widely used in electrical engineering and electronics due to its high corrosion resistance and low electrical resistance. The addition of specific alloys such as chromium and nickel enhances its conductivity, making it an ideal choice for conducting electricity efficiently. In electrical conductivity applications, special steel exhibits low resistivity, allowing for the smooth flow of electrical current without significant loss of energy. Its low resistance minimizes the generation of heat, which is crucial for preventing overheating and ensuring the efficient operation of electrical components. Special steel also possesses excellent magnetic properties, making it suitable for applications that require both electrical conductivity and magnetic strength. This property is particularly useful in the production of transformers, motors, and generators. Moreover, special steel is highly durable and can withstand harsh environmental conditions, making it suitable for outdoor applications. Its corrosion resistance prevents the formation of rust, ensuring a long lifespan and consistent performance even in challenging environments. In summary, special steel is an excellent choice for electrical conductivity applications due to its low electrical resistance, high corrosion resistance, and exceptional durability. Its unique properties make it a preferred material in various industries that rely on efficient and reliable electrical conductivity.

- Q: Can special steel be used for making marine components?

- Yes, special steel can be used for making marine components. Special steel is often chosen for its corrosion resistance, strength, and durability, which are crucial properties required for components used in marine environments. These components need to withstand exposure to seawater, harsh weather conditions, and extreme pressures. Special steel alloys such as stainless steel or duplex steel are commonly used for marine applications due to their excellent resistance to corrosion and ability to maintain structural integrity in marine environments.

- Q: How does special steel contribute to the longevity of products?

- Special steel contributes to the longevity of products in several ways. Firstly, special steel is known for its exceptional strength and durability. It is specifically engineered to withstand extreme conditions, such as high temperatures, pressure, and corrosive environments. This makes it ideal for use in various industries, including aerospace, automotive, and construction. The high strength of special steel allows products to withstand heavy loads and resist deformation, ensuring they remain intact and functional for an extended period. For instance, in the construction industry, special steel is commonly used in structural components like beams and columns, which provide the necessary support and stability to buildings over many years. Moreover, special steel has excellent resistance to wear and abrasion. It can withstand constant friction, impact, and contact with other materials without significant deterioration. This characteristic is crucial in industries where products are subject to continuous use, such as machinery, tools, and equipment. The use of special steel in these applications ensures that the products remain in good working condition for a longer time, reducing the need for frequent repairs or replacements. Furthermore, special steel has exceptional corrosion resistance, making it highly resistant to rust and other forms of corrosion. This property is particularly beneficial in products exposed to harsh environments or chemicals, such as marine vessels, pipelines, and chemical processing equipment. By using special steel, manufacturers can significantly extend the lifespan of these products, minimizing the risk of failure or breakdown due to corrosion. In summary, special steel contributes to the longevity of products by providing superior strength, durability, wear resistance, and corrosion resistance. Its exceptional properties allow products to withstand harsh conditions, heavy loads, and continuous use, ensuring they remain functional and reliable for an extended period. By incorporating special steel into their designs, manufacturers can significantly enhance the lifespan of their products, leading to cost savings, improved reliability, and customer satisfaction.

- Q: How does special steel contribute to the manufacturing of springs?

- Special steel plays a crucial role in the manufacturing of springs due to its unique properties and characteristics. Springs are mechanical components that store and release mechanical energy, and special steel provides the necessary strength, durability, and resilience for these applications. One of the key contributions of special steel to spring manufacturing is its high tensile strength. Special steel alloys are designed to have a higher strength-to-weight ratio compared to regular steels, allowing springs to withstand heavy loads and high stresses without deforming or breaking. This property ensures the longevity and reliability of springs, even in demanding applications such as automotive suspensions or industrial machinery. Furthermore, special steel exhibits excellent elasticity and resilience. Springs need to retain their shape and performance over repeated cycles of compression and extension. Special steel alloys are formulated to have a high elastic limit, meaning they can be deformed significantly and still return to their original shape without permanent deformation. This property allows springs to absorb and release energy reliably, providing the desired mechanical functionality in various applications. Another important contribution of special steel to spring manufacturing is its resistance to fatigue and corrosion. Springs are often subjected to cyclic loading, which can lead to fatigue failure over time. Special steel alloys are designed to have enhanced fatigue resistance, allowing springs to endure millions of cycles without failure. Additionally, special steel can be further treated or coated to enhance its corrosion resistance, which is crucial for springs exposed to harsh environments or chemicals. In conclusion, special steel significantly contributes to the manufacturing of springs by providing high tensile strength, excellent elasticity and resilience, fatigue resistance, and corrosion resistance. These properties ensure the durability, performance, and longevity of springs, making them essential components in various industries such as automotive, aerospace, and manufacturing.

- Q: What are the specific requirements for special steel used in the railway sector?

- Ensuring the safety, durability, and efficient operation of railway infrastructure in the railway sector relies heavily on meeting the specific requirements for special steel. Some of the key requirements include: 1. Exceptional strength is essential for the special steel used in the railway sector to withstand heavy loads, vibrations, and impacts. This is crucial to maintain the structural integrity of tracks, bridges, and other components. 2. To minimize the need for frequent maintenance and replacement, special steel must have excellent wear resistance as railway tracks and wheels experience significant wear due to continuous contact and friction. 3. Railway components are subjected to constant cyclic loading, which demands high fatigue resistance in the steel. This ensures they can withstand repetitive stress and prevents fatigue failures. 4. Special steel must possess good corrosion resistance to prevent rusting and degradation, thereby ensuring a longer service life in the face of various environmental conditions such as moisture, extreme temperatures, and chemicals. 5. In certain applications like rail joints and fasteners, special steel is exposed to high temperatures due to friction and stresses. Good heat resistance is necessary for the steel to maintain its mechanical properties under such conditions. 6. Good weldability of special steel is essential to enable efficient and reliable joining of components during manufacturing and maintenance processes in the railway sector. 7. The steel must exhibit sufficient ductility and toughness to absorb energy and resist fracture in the event of a collision or impact, ensuring passenger safety. 8. Special steel used in the railway sector must maintain its dimensional stability under varying temperatures and loads to prevent deformation and ensure proper alignment of tracks and components. Meeting these specific requirements for special steel in the railway sector is crucial to ensure the safety, reliability, and longevity of railway infrastructure. This contributes to the smooth operation of the entire transport network.

- Q: How does the heat treatment process affect the properties of special steel?

- The heat treatment process can significantly affect the properties of special steel. It involves heating the steel to a specific temperature and then cooling it at a controlled rate to alter its microstructure. This process can change the steel's hardness, strength, toughness, and even its resistance to corrosion. By manipulating the heat treatment parameters, such as temperature, time, and cooling rate, manufacturers can tailor the properties of special steel to meet specific requirements for different applications.

- Q: What are the different heat treatment methods for special steel?

- There are several heat treatment methods for special steel, including annealing, quenching, tempering, and normalizing. Annealing involves heating the steel to a specific temperature and then slowly cooling it to improve its machinability and reduce internal stresses. Quenching is a rapid cooling process that makes the steel harder and more brittle, but also increases its strength. Tempering is a heat treatment process that involves reheating quenched steel to a specific temperature and then cooling it again to improve its toughness and reduce brittleness. Normalizing is another heat treatment method that involves heating the steel to a specific temperature and then cooling it in still air to improve its mechanical properties and refine its grain structure.

- Q: How does special steel contribute to the manufacturing of precision instruments?

- The manufacturing of precision instruments heavily relies on the use of special steel. This material possesses unique characteristics and properties that make it an ideal choice for such applications. To begin with, special steel boasts exceptional strength and durability, enabling precision instruments to withstand extreme conditions, heavy loads, and repetitive use. This quality ensures the longevity and reliability of these instruments, which is of utmost importance in critical industries such as aerospace, automotive, and medical. Furthermore, special steel exhibits excellent corrosion resistance, safeguarding the instruments from deterioration over time. This becomes particularly crucial for precision instruments that are exposed to a wide array of elements, chemicals, or moisture during their operation or storage. In addition, special steel provides high thermal stability, allowing precision instruments to maintain their accuracy even in varying temperature environments. This proves vital for instruments used in industries where temperature fluctuations may impact their performance, such as laboratories or manufacturing plants. Moreover, special steel can be tailored and customized to meet specific design requirements. It can be easily machined, formed, or welded into intricate shapes and parts, enabling manufacturers to create precision instruments with complex geometries and tight tolerances. This level of precision is essential for instruments utilized in fields like metrology, microscopy, or nanotechnology. Additionally, special steel possesses excellent magnetic properties, which can be advantageous for precision instruments that rely on magnetic fields for their operation. Examples of such instruments include magnetic resonance imaging (MRI) machines, compasses, or magnetometers. In conclusion, special steel significantly contributes to the manufacturing of precision instruments by providing strength, durability, corrosion resistance, thermal stability, customization options, and magnetic properties. These characteristics guarantee the performance, accuracy, and longevity of precision instruments, rendering them indispensable in various industries.

- Q: What are the properties of high-speed stainless steel?

- High-speed stainless steel possesses several key properties that make it highly desirable for various applications. Firstly, it exhibits exceptional corrosion resistance, ensuring its longevity and reliability even in harsh environments. Secondly, it has excellent strength and durability, allowing it to withstand high temperatures and heavy loads without deformation or failure. Additionally, high-speed stainless steel offers good machinability, enabling ease of fabrication and precise shaping. Lastly, it maintains its sharpness and cutting efficiency even under extreme heat and friction, making it ideal for cutting tools and high-speed machinery.

Send your message to us

Chrome Price Q235 CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords