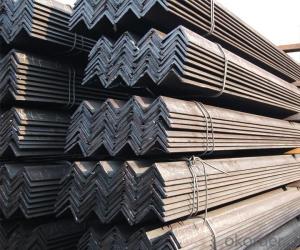

Hot Rolled Steel Equal Angle Steel Angles,Mild Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Equal Angle Steel Angles,Mild Steel Angle Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Equal Angle Steel Angles,Mild Steel Angle Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Equal Angle Steel Angles,Mild Steel Angle Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Sizes: 25mm-250mm | ||||||||||

a*t | ||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||

Alloy No | Grade | Element (%) | ||||||||

C | Mn | S | P | Si | ||||||

|

|

|

|

|

|

| ||||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | ||||

|

|

|

|

|

|

| ||||

Alloy No | Grade | Yielding strength point( Mpa) | ||||||||

Thickness (mm) | ||||||||||

≤16 | >16--40 | >40--60 | >60--100 | |||||||

≥ | ||||||||||

|

|

|

|

|

| |||||

Q235 | B | 235 | 225 | 215 | 205 | |||||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | |||||||

Thickness (mm) | ||||||||||

| ≤16 | >16--40 | >40--60 | >60--100 | ||||||

≥ | ||||||||||

|

|

|

|

|

|

| ||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | ||||

Packaging & Delivery of Hot Rolled Hot Rolled Steel Equal Angle Steel Angles,Mild Steel Angle Bar

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the welding techniques used for steel angles?

- There are several welding techniques that can be used for steel angles, depending on the specific application and desired outcome. Some of the commonly used welding techniques are: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW involves the use of a consumable electrode coated in flux. This technique is versatile, cost-effective, and suitable for various thicknesses of steel angles. 2. Gas Metal Arc Welding (GMAW): Also known as MIG (Metal Inert Gas) welding, GMAW uses a wire electrode fed through a welding gun. The wire is melted and joined with the base metal, while an inert gas shield protects the weld from atmospheric contamination. GMAW is commonly used for thin to medium thickness steel angles. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuous wire electrode. However, the wire is filled with flux, eliminating the need for an external shielding gas. FCAW is suitable for both indoor and outdoor applications and is known for its high deposition rates. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW utilizes a non-consumable tungsten electrode and a separate filler metal if needed. This technique produces high-quality, precise welds and is commonly used for thinner steel angles or when a high degree of control is required. 5. Submerged Arc Welding (SAW): SAW involves the use of a continuously fed wire electrode submerged in a granular flux. The flux acts as a protective layer, preventing atmospheric contamination and enhancing weld quality. SAW is commonly used for thicker steel angles or in situations where high deposition rates are required. It is important to consider factors such as the thickness of the steel angles, the environment in which the welding will take place, and the desired quality and strength of the weld when selecting the appropriate welding technique. Consulting with a professional welder or engineer can help determine the best technique for a specific application.

- Q: Can steel angles be cut to size?

- Certainly! Steel angles are capable of being cut to the desired size. These versatile structural materials, commonly referred to as L-shaped angles, find extensive use in the construction and manufacturing sectors. One can effortlessly tailor their length using a variety of cutting tools such as saws, plasma cutters, or angle grinders. This enables customization and guarantees a seamless fit for the steel angles in their intended purpose. It is crucial to adhere to suitable safety precautions and utilize appropriate equipment while cutting these angles, given their formidable strength and durability.

- Q: What are the different uses for stainless steel angles?

- Stainless steel angles find widespread application in diverse industries and fields. Here are several examples of the different ways in which stainless steel angles are utilized: 1. For structural support: In construction and engineering projects, stainless steel angles serve as essential elements for providing stability, strength, and longevity. They are ideal for framing structures, supporting beams, and reinforcing load-bearing structures. 2. In architecture: Stainless steel angles are commonly employed in architectural designs to create decorative trims, frames, and accents. They add aesthetic appeal to buildings, bridges, and other structures. 3. In industrial equipment: Stainless steel angles play a crucial role in the manufacturing and assembly of industrial machinery, conveyor systems, and robotics. They provide stability and reinforcement in heavy-duty applications. 4. In furniture and shelving: Stainless steel angles are frequently used in the construction of furniture and shelving units. They offer stability and support, ensuring long-lasting durability for tables, chairs, storage racks, and display shelves. 5. In the automotive industry: Stainless steel angles find various applications in the automotive sector. They are commonly used in the production of frames, chassis, brackets, and suspension components, offering strength and resistance to corrosion. 6. In marine applications: Due to their resistance to corrosion, stainless steel angles are highly suitable for marine environments. They are commonly used in boat building, ship fittings, and offshore structures, enduring harsh saltwater conditions. 7. In the food processing and medical industries: Stainless steel angles are extensively utilized in the food processing and medical sectors. They are corrosion-resistant, easy to clean, and comply with strict hygiene standards. Stainless steel angles are commonly found in the construction of food processing equipment, surgical instruments, and medical devices. 8. In decorative and artistic projects: Stainless steel angles contribute to artistic and decorative endeavors. Sculptors, designers, and metalworkers often employ them to create visually appealing structures, sculptures, and installations. To summarize, stainless steel angles serve multiple purposes in industries such as construction, architecture, industrial manufacturing, automotive, marine, furniture, food processing, medical, and art. Their strength, durability, and resistance to corrosion make them a versatile and dependable choice in various settings.

- Q: How do you determine the deflection of a steel angle?

- To determine the deflection of a steel angle, you need to consider various factors such as the applied load, the moment of inertia of the angle, the length of the span, and the modulus of elasticity of the steel. By utilizing the appropriate formulas and equations for deflection, such as the Euler-Bernoulli beam theory, you can calculate the deflection of the steel angle under the given load and conditions.

- Q: How do steel angles contribute to the overall sustainability of a building?

- A building's overall sustainability is enhanced by steel angles in various ways. To begin with, steel angles are constructed from recycled materials, making them a sustainable choice for building purposes. Steel is one of the world's most recycled materials, boasting a high recycling rate. This reduces the necessity for new resources and lessens the environmental impact of extraction and production. Additionally, steel angles offer structural efficiency, enabling them to support greater loads with less material compared to other building materials. This efficiency reduces the amount of steel needed for construction, minimizing the carbon footprint associated with steel production and transportation. Furthermore, steel angles are extremely durable and long-lasting. They possess high resistance to corrosion, fire, and pests, thereby reducing the maintenance and replacement requirements over the building's lifespan. This durability results in reduced waste generation and lower life-cycle costs, ultimately making the building more sustainable in the long term. Moreover, steel angles are versatile and easily reusable or repurposed. In the event of renovation or demolition, salvaging and reusing the steel angles in other construction projects is feasible. This promotes a circular economy approach, minimizing waste generation and contributing to the overall sustainability of the construction industry. Lastly, steel angles possess excellent thermal properties that can enhance a building's energy efficiency. They can be utilized as part of the building envelope, aiding in the reduction of energy consumption for heating and cooling. By improving insulation and airtightness, steel angles contribute to lower energy demand and reduced greenhouse gas emissions. In conclusion, steel angles contribute to a building's overall sustainability through their recycled content, structural efficiency, durability, recyclability, and energy-saving properties. Opting for steel angles in construction allows for resource conservation, waste reduction, and a minimized environmental impact in the built environment.

- Q: What is the typical tolerance for steel angles?

- The specific application and industry standards determine the typical tolerance for steel angles. Generally, the industry standard allows for a tolerance of ±1/8 inch or ±3 millimeters. This means that the actual dimensions of the angle can differ by up to 1/8 inch or 3 millimeters from the specified dimensions. It is worth noting that these tolerances may differ depending on the grade of steel and the manufacturing process used. Consequently, it is vital to refer to the appropriate industry standards or specifications for the specific project in order to ascertain the precise tolerance requirements for steel angles in that particular application.

- Q: Are steel angles available in non-standard sizes or custom shapes?

- Yes, steel angles are available in non-standard sizes and can be custom made to specific shapes based on the requirements of the project or design.

- Q: How do steel angles contribute to the overall stability of a building frame?

- Steel angles contribute to the overall stability of a building frame by providing structural support and reinforcement. They are commonly used as braces and connections in building frames to increase their load-bearing capacity and resist forces such as wind, earthquakes, and heavy loads. The angles help distribute and transfer the loads throughout the structure, enhancing its stability and preventing deformation or collapse.

- Q: Are steel angles suitable for use in high-rise buildings?

- Steel angles are indeed suitable for high-rise buildings. They are frequently utilized as structural elements in such buildings because of their exceptional strength, durability, and versatility. Due to their ability to endure heavy loads and provide structural support, steel angles are ideal for use in beams, columns, and bracing systems. Moreover, they can be easily fabricated and installed, resulting in efficient construction processes. Furthermore, steel angles can be tailored to fit specific structural requirements in terms of size and shape, allowing for flexibility in both design and construction. In conclusion, steel angles are a dependable and cost-effective option for high-rise buildings, as they possess the necessary strength and stability required for such structures.

- Q: How do steel angles perform in terms of durability and longevity?

- Steel angles are widely recognized for their exceptional durability and longevity. Thanks to their composition, which includes a substantial amount of iron and carbon, steel angles possess remarkable strength and resistance to various forms of wear and tear. They have the ability to withstand heavy loads, extreme temperatures, and exposure to corrosive elements, thereby making them highly durable and suitable for a wide range of applications. In terms of their longevity, steel angles boast an impressive lifespan. They are specifically engineered to endure the test of time and maintain their structural integrity over extended periods. The inherent strength and resilience of steel angles ensure that they do not easily deteriorate, thus making them a reliable choice for long-term usage. What's more, steel angles require minimal maintenance to preserve their durability and longevity. Regular inspections and cleaning can effectively prevent the accumulation of rust and other forms of corrosion, thereby ensuring that the angles remain in optimal condition throughout their lifespan. Additionally, steel angles can be galvanized or coated with protective layers to further enhance their durability and resistance against environmental factors. Galvanization involves the application of a layer of zinc to the surface of the steel, providing an additional barrier against rust and corrosion. Alternatively, the angles can be coated with epoxy or powder coatings to enhance their durability and longevity in specific environments. All in all, steel angles are renowned for their exceptional durability and longevity. They offer a reliable and long-lasting solution for a variety of structural and construction needs, which explains their popularity in numerous industries.

Send your message to us

Hot Rolled Steel Equal Angle Steel Angles,Mild Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords