BS4449 460B Reinforcing Deformed Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

BS4449 460B Reinforcing Deformed Steel Bars

Details of BS4449 460B Reinforcing Deformed Steel Bars

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of BS4449 460B Reinforcing Deformed Steel Bars

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

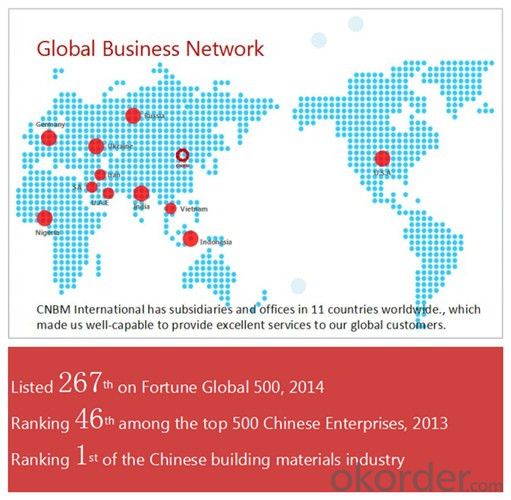

CNBM Introduction of BS4449 460B Reinforcing Deformed Steel Bars

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of BS4449 460B Reinforcing Deformed Steel Bars

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different methods of surface peening for special steel?

- Some of the different methods of surface peening for special steel include shot peening, glass bead peening, and laser peening. Shot peening involves bombarding the surface of the steel with small spherical shots to create compressive stresses, which helps to increase the strength and durability of the material. Glass bead peening uses small glass beads instead of shots to achieve a similar effect. Laser peening, on the other hand, involves using high-energy laser pulses to generate shock waves on the surface of the steel, resulting in improved fatigue resistance and damage tolerance. Overall, these methods can enhance the performance and lifespan of special steel components.

- Q: What are the specific requirements for special steel used in the railway wheel industry?

- The specific requirements for special steel used in the railway wheel industry include high strength and toughness, excellent wear resistance, good heat resistance, and the ability to withstand heavy loads and impact. The steel must also have low levels of impurities to ensure its durability and longevity in the demanding railway environment. Additionally, it should possess good fatigue resistance to withstand repeated stress cycles and meet specific dimensional and mechanical property standards set by the industry.

- Q: How is high-temperature steel used in the production of furnace components?

- High-temperature steel is used in the production of furnace components due to its exceptional heat resistance and strength. It can withstand the extreme temperatures inside the furnace without losing its structural integrity, making it ideal for constructing furnace walls, tubes, and other critical components. Additionally, high-temperature steel helps maintain a stable and efficient heating environment, ensuring optimal performance and longevity of the furnace.

- Q: Can special steel be used in the chemical processing industry?

- Yes, special steel can be used in the chemical processing industry. Special steel alloys are designed to have excellent resistance to corrosion, high temperatures, and chemical reactions, making them suitable for use in various chemical processes. These steels can withstand harsh environments, such as exposure to corrosive chemicals, acids, and high-pressure conditions, ensuring the longevity and reliability of equipment and structures in the chemical processing industry.

- Q: How does special steel contribute to reducing weight in applications?

- Special steel contributes to reducing weight in applications through its unique properties and manufacturing processes. Special steel alloys are engineered to have high strength-to-weight ratios, allowing them to provide the same structural integrity as conventional steel but at a reduced weight. These alloys often contain elements like chromium, nickel, and molybdenum, which enhance their strength and durability. Additionally, special steel can be manufactured through advanced techniques such as hot rolling, cold rolling, and heat treatment. These processes further refine the steel's microstructure, improving its mechanical properties while maintaining a lightweight composition. By using special steel in various applications, such as automotive parts, aerospace components, and construction materials, manufacturers can achieve weight reduction without compromising performance or safety.

- Q: Can special steel be used in the renewable energy industry?

- Yes, special steel can be used in the renewable energy industry. Special steel offers high strength, corrosion resistance, and durability, making it suitable for various applications in renewable energy, such as wind turbines, solar panels, and hydroelectric power systems. It can withstand harsh environmental conditions and provide structural stability, contributing to the efficiency and longevity of renewable energy equipment.

- Q: How does the carbon content affect the properties of special steel?

- The carbon content in special steel plays a crucial role in determining its properties. The addition of carbon to steel alters its microstructure and influences various mechanical and physical properties. The primary effect of carbon content is on the hardness and strength of the steel. Increasing the carbon content in special steel leads to an increase in its hardness. This is because carbon atoms occupy the interstitial sites in the iron lattice, which creates a distortion in the crystal structure, making it more resistant to deformation. Higher carbon content also results in a greater martensitic transformation during heat treatment, which further enhances the hardness of the material. Furthermore, the strength of special steel is significantly influenced by carbon content. Higher carbon levels lead to increased strength due to the formation of stronger and more numerous carbide precipitates. These carbides act as obstacles to dislocation movement, making it more difficult for the steel to deform under load. However, it is important to note that the increase in carbon content also comes with some trade-offs. As the carbon content rises, the ductility of the steel decreases. This means that the material becomes less able to deform without fracturing. High carbon content can make the steel brittle, reducing its toughness and impact resistance. In addition to hardness and strength, carbon content affects other properties of special steel. It influences the steel's wear resistance, as higher carbon content leads to the formation of harder carbides that can resist wear and abrasion. Carbon also affects the steel's machinability, with higher carbon content making the material more difficult to machine due to increased hardness. In conclusion, the carbon content has a significant impact on the properties of special steel. It affects the hardness, strength, ductility, toughness, wear resistance, and machinability of the material. Therefore, careful consideration of the desired properties and application requirements is necessary when determining the appropriate carbon content for special steel.

- Q: What are the different casting techniques used for special steel?

- Some of the different casting techniques used for special steel include investment casting, sand casting, continuous casting, and centrifugal casting. Each technique has its own advantages and is chosen based on factors such as the complexity of the steel part, the desired quality, and cost considerations.

- Q: How does special steel perform in marine applications?

- Special steel performs exceptionally well in marine applications due to its excellent corrosion resistance and high strength. The steel is specifically designed to withstand harsh marine environments, such as saltwater, which can cause corrosion and deterioration in other materials. Its resistance to corrosion ensures durability and longevity, making it an ideal choice for various marine components and structures, including ships, offshore platforms, and underwater equipment. Additionally, the high strength of special steel enhances the structural integrity and load-bearing capacity of marine applications, providing superior performance and safety in challenging conditions.

- Q: What are the main applications of special steel in the chemical industry?

- Special steel is widely used in the chemical industry due to its excellent properties such as corrosion resistance, high temperature resistance, and strength. It is primarily used in the construction of chemical processing equipment, including reactors, pipes, valves, and storage tanks. Special steel ensures the safe and efficient handling of corrosive chemicals, as well as the prevention of leaks and contamination. Additionally, it is utilized in the production of catalysts, which play a crucial role in various chemical reactions. Overall, special steel enables the chemical industry to maintain high product quality, operational efficiency, and safety standards.

Send your message to us

BS4449 460B Reinforcing Deformed Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords