Low Cost_Various High Quality Equal / Unequal Steel Angle_Angle Steel_Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Low Cost_Various High Quality Equal / Unequal Steel Angle_Angle Steel_Angle Bars

Detailed Informaion

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Quick Details

Standard:AISI,ASTM,BS,GB,JIS,EN

Size:45*30*4-200*125*18

Length: 6-16m

Technique: hot rolled

Grade:SS400, ST37-2, A36, S235JRG1, Q235, Q345 etc.

Type:EqualCertification:SGS,ISO

Inspection:accept BV SGS inspect

Specification

Specification | Weight | Specification | Weight |

Leg length*leg length*thickness |

| Leg length*leg length*thickness | (kg/m) |

(mm) | (kg/m) | (mm) |

|

25*25*3 | 1.124 | 90*90*8 | 10.946 |

25*25*4 | 1.459 | 90*90*10 | 13.476 |

30*30*3 | 1.373 | 100*100*6 | 9.366 |

30*30*4 | 1.786 | 100*100*7 | 10.83 |

40*40*3 | 1.852 | 100*100*8 | 12.276 |

40*40*4 | 2.422 | 100*100*10 | 15.12 |

40*40*5 | 2.976 | 100*100*12 | 17.898 |

45*45*3 | 2.088 | 110*110*7 | 11.928 |

45*45*4 | 2.736 | 110*110*8 | 13.532 |

45*45*5 | 3.369 | 110*110*10 | 16.69 |

50*50*3 | 2.332 | 110*110*12 | 19.782 |

50*50*4 | 3.059 | 125*125*8 | 15.504 |

50*50*5 | 3.77 | 125*125*10 | 19.133 |

50*50*6 | 4.465 | 125*125*12 | 22.696 |

63*63*5 | 4.822 | 125*125*14 | 26.193 |

63*63*6 | 5.721 | 140*140*10 | 21.488 |

63*63*8 | 7.469 | 140*140*12 | 25.522 |

70*70*5 | 5.397 | 140*140*14 | 29.49 |

70*70*6 | 6.406 | 160*160*10 | 24.729 |

70*70*7 | 7.398 | 160*160*12 | 29.391 |

70*70*8 | 8.373 | 160*160*14 | 33.987 |

75*75*5 | 5.818 | 160*160*16 | 38.518 |

75*75*6 | 6.905 | 180*180*12 | 33.159 |

75*75*7 | 7.976 | 180*180*14 | 38.383 |

75*75*8 | 9.03 | 180*180*16 | 43.542 |

75*75*10 | 11.089 | 180*180*18 | 48.634 |

80*80*6 | 7.376 | 200*200*14 | 42.894 |

80*80*7 | 8.525 | 200*200*16 | 48.68 |

80*80*8 | 9.658 | 200*200*18 | 54.401 |

80*80*10 | 11.874 | 200*200*20 | 60.056 |

90*90*6 | 8.35 | 200*200*24 | 71.168 |

90*90*7 | 9.656 |

|

|

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

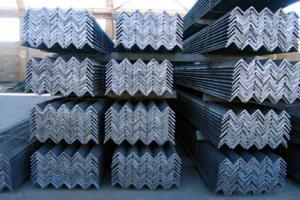

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main factors affecting the formability of special steel?

- Several factors influence the formability of special steel, similar to other types of steel. These factors encompass the composition, microstructure, mechanical properties, temperature, and strain rate of the steel. The composition of special steel plays a vital role in determining its formability. The presence of alloying elements, such as chromium, nickel, molybdenum, and vanadium, can significantly impact the steel's ability to be shaped. These elements have the power to modify the steel's strength, ductility, and resistance to deformation. Another crucial factor influencing the formability of special steel is its microstructure. Fine-grained steels generally exhibit superior formability compared to coarse-grained steels. Additionally, the existence of non-metallic inclusions, like sulfides and oxides, can act as stress concentrators and promote crack formation, thereby influencing formability. The mechanical properties of special steel, including yield strength, tensile strength, and elongation, directly affect its formability. Steels with higher yield strength typically pose greater difficulty in shaping as they require more force for deformation. However, steels with high elongation can undergo more significant plastic deformation before failure, making them more formable. Temperature is also a critical factor impacting the formability of special steel. Elevated temperatures enhance the steel's ductility and make it easier to shape. This is due to the reduction in yield strength and increased movement of dislocations within the crystal structure. However, excessively high temperatures can lead to grain growth, negatively impacting formability. The strain rate, which refers to the rate of deformation applied to the steel, also influences formability. Higher strain rates can result in strain hardening, making the steel stronger but less formable. Conversely, lower strain rates allow for greater plastic deformation and improved formability. In conclusion, achieving the desired formability and shaping capabilities of special steel in various applications necessitates an understanding and optimization of its composition, microstructure, mechanical properties, temperature, and strain rate.

- Q: What are the different surface coating methods used for special steel?

- There are several surface coating methods that are commonly used for special steel to enhance its properties and protect it from various environmental factors. These methods include: 1. Galvanizing: This is a process in which a layer of zinc is applied to the surface of the steel. It provides excellent corrosion resistance and can be done through hot-dip galvanizing or electroplating. 2. Electroplating: In this method, a thin layer of metal such as chromium, nickel, or copper is deposited onto the steel surface through an electrochemical process. This improves the steel's appearance, wear resistance, and corrosion resistance. 3. Powder coating: Powder coating involves applying a dry powder to the steel surface, which is then heated and fused to form a protective layer. It provides excellent durability, weather resistance, and aesthetic appeal. 4. Thermal spray coating: This method involves spraying a molten or heated material onto the steel surface, which then solidifies to form a protective coating. Materials commonly used for thermal spray coating include metals, ceramics, and polymers. 5. Paint coating: Painting is a commonly used method for surface coating. Different types of paints, such as epoxy, polyurethane, or acrylic, can be applied to the steel surface to provide protection against corrosion, chemicals, and UV radiation. 6. PVD coating: Physical Vapor Deposition (PVD) is a process in which a thin film of a material, such as titanium nitride or diamond-like carbon, is deposited onto the steel surface through a vacuum deposition process. PVD coatings enhance hardness, wear resistance, and appearance. 7. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to special steel. This process involves creating an oxide layer on the steel surface through an electrochemical reaction, which improves corrosion resistance and adds a decorative finish. These surface coating methods are essential for special steel as they provide enhanced protection against corrosion, wear, and other environmental factors, thereby extending the lifespan and improving the performance of the steel. The choice of coating method depends on the specific requirements and desired properties of the steel.

- Q: What are the disadvantages of using special steel?

- One of the main disadvantages of using special steel is its high cost. Special steel is typically more expensive to produce and purchase compared to regular steel. Additionally, the production process for special steel often requires specific techniques and equipment, which can further increase costs. Another disadvantage is the limited availability of special steel. It may not be readily accessible in all regions, leading to longer lead times and potential supply chain issues. Moreover, special steel may have lower formability and machinability compared to regular steel, making it more challenging to work with and shape as needed.

- Q: What are the different passivation techniques used for special steel?

- There are several passivation techniques used for special steel, including chemical passivation, electrochemical passivation, and mechanical passivation. Chemical passivation involves the use of acidic solutions to remove impurities from the steel's surface and create a passive oxide layer. Electrochemical passivation utilizes an electrical current to form the protective oxide layer on the steel's surface. Mechanical passivation involves processes such as shot blasting or grinding to remove contaminants and improve the surface quality of the steel. These techniques help enhance the corrosion resistance and overall performance of special steel.

- Q: What are the requirements for special steel used in construction equipment manufacturing?

- The requirements for special steel used in construction equipment manufacturing are stringent and specific. Here are some key requirements: 1. High strength: Special steel used in construction equipment manufacturing should possess high tensile strength and yield strength to withstand heavy loads and stresses. This ensures the equipment's durability and longevity. 2. Toughness: The steel should have excellent toughness to resist fracture and deformation under impact or dynamic loading conditions. This is crucial for construction equipment operating in challenging environments. 3. Wear resistance: Construction equipment is subjected to abrasive forces, such as digging, scraping, and crushing. Therefore, the special steel should exhibit high wear resistance to prevent premature wear and failure. 4. Corrosion resistance: Construction equipment often operates in harsh environments, such as construction sites, mines, and marine applications. The steel should have good corrosion resistance to prevent rusting and corrosion, which can weaken the equipment's structural integrity. 5. Weldability: Construction equipment manufacturing involves various fabrication processes, including welding. The special steel should have good weldability to ensure proper joining and structural integrity without compromising strength. 6. Heat resistance: In certain construction applications, equipment may be subjected to high temperatures or thermal cycling. Special steel should have good heat resistance to maintain its mechanical properties and structural stability under these conditions. 7. Formability: Construction equipment often consists of complex shapes and structures. The steel should have good formability to allow for easy shaping and fabrication into the desired components without compromising its mechanical properties. 8. Cost-effectiveness: While meeting the above requirements, special steel used in construction equipment manufacturing should also be cost-effective. This means balancing the desired properties with the economic feasibility of production and procurement. Meeting these requirements ensures that the special steel used in construction equipment manufacturing can withstand the demanding conditions, provide long-term durability, and ensure the safety and efficiency of the equipment. Additionally, compliance with industry standards and regulations is essential to guarantee the quality and reliability of the steel used in construction equipment manufacturing.

- Q: How is nitriding steel used in the production of tools and dies?

- Nitriding steel is used in the production of tools and dies through a process called nitriding. This involves introducing nitrogen into the surface of the steel, which forms a hard layer of nitrides, increasing the overall hardness, wear resistance, and corrosion resistance of the material. This enhanced surface hardness makes the tools and dies more durable and long-lasting, allowing them to withstand the high stresses and temperatures experienced during cutting, forming, and shaping processes. Additionally, nitriding steel can also improve the fatigue strength and reduce the friction of the tools and dies, enhancing their performance and efficiency in various industrial applications.

- Q: How is structural steel used in building construction?

- Structural steel is a crucial material in building construction as it provides strength, durability, and flexibility to the overall structure. It is used to create the framework or skeleton of a building, including beams, columns, and trusses. These steel components support the weight of the building and distribute it evenly, ensuring stability and safety. Additionally, structural steel can be easily fabricated and assembled on-site, making it a cost-effective and efficient solution for various types of construction projects.

- Q: How is wear-resistant tool steel used in the production of cutting tools?

- Wear-resistant tool steel is commonly used in the production of cutting tools due to its high hardness and resistance to wear. This steel is able to withstand the abrasive forces and high temperatures generated during cutting operations, resulting in longer tool life and improved cutting performance. The wear-resistant tool steel is typically used to manufacture various cutting tools such as drills, milling cutters, saw blades, and lathe tools, ensuring durability and efficiency in metalworking and machining processes.

- Q: What are the main characteristics of corrosion-resistant castings?

- Corrosion-resistant castings have been designed to endure the destructive effects of corrosion, a natural process that causes the deterioration of metal surfaces due to chemical reactions. These castings possess several key features that render them impervious to corrosion. First and foremost, corrosion-resistant castings are fashioned from specific alloys or materials that possess inherent resistance to corrosion. These materials may consist of stainless steel, nickel-based alloys, or high-performance alloys such as Inconel or Hastelloy. These alloys contain elements like chromium, molybdenum, or nickel, which generate a protective layer on the casting's surface, preventing the infiltration of corrosive agents into the underlying metal. Secondly, meticulous casting techniques are employed in the production of these castings to ensure a solid and defect-free structure. This is crucial in warding off the penetration of corrosive substances into the castings. Techniques such as investment casting or vacuum casting are commonly utilized to achieve a high degree of precision and quality. An additional significant characteristic of corrosion-resistant castings is their ability to withstand various types of corrosion, including general corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking. General corrosion refers to the gradual and uniform deterioration of the metal surface, while pitting corrosion leads to the formation of localized holes or pits. Crevice corrosion occurs in confined spaces such as gaps or joints, and stress corrosion cracking arises from the combined effects of stress and a corrosive environment. Corrosion-resistant castings are designed to endure all these types of corrosion, ensuring long-lasting durability and dependability. Furthermore, corrosion-resistant castings often undergo additional surface treatments or coatings to enhance their resistance to corrosion. These treatments may encompass passivation, where the surface is treated chemically to create a protective oxide layer, or the application of protective coatings such as epoxy or polyurethane. These treatments provide an additional layer of defense against corrosive agents, prolonging the lifespan of the castings. In conclusion, the primary characteristics of corrosion-resistant castings include the utilization of corrosion-resistant alloys, meticulous casting techniques, resistance to various types of corrosion, and the application of surface treatments or coatings. These characteristics ensure that these castings can endure harsh environments and maintain their structural integrity over time, making them ideal for applications where corrosion poses a significant concern.

- Q: Can special steel be coated or plated?

- Yes, special steel can be coated or plated to enhance its properties or provide additional protection against corrosion or wear.

Send your message to us

Low Cost_Various High Quality Equal / Unequal Steel Angle_Angle Steel_Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords