Din 1.7131 16mncr15 Alloy Structure Steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

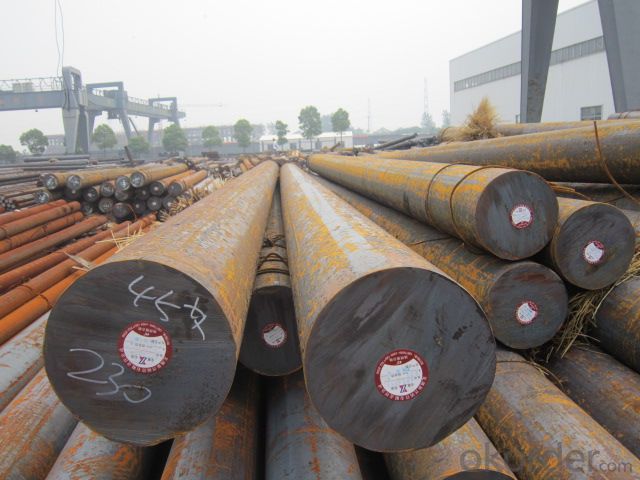

Din 1.7131 16mncr15 Alloy Structure Steel

Product information:

1.Standard: Chinese GB50221-2001, Or Equivalent.

2.Material: Grade Q235, or equivalent to ASTM A36.

Grade Q345, equivalent to ASTM A572.

3.Section: I / H section, or customlized profile.

4.Sand Blast: Sweden SA 2.5 Sand blasting.

5.Welding: Single level butt welding, fillet welding by electric arc welding, and Gas shielded welding.

6.Surface treatment: Zinc primer, Red primer, Hot-dip Galvanize and Powder painted.

7.Certification: ISO quality system.

8.Advantages:

a.Light weight with high strength.

b.Corrosion resistance.

c.Labor saving, time saving and cost saving.

d.Long time durable.

| What are details of din 1.7131 16mncr15 /alloy structure steel ? | ||||

| Name | Songshun din 1.7131 16mncr15 /alloy structure steel | |||

| Features | 1.Good hardenability and machinability. | |||

| 2.For Large cross-section parts,it can get high surface hardness and abrasive resistance. | ||||

| 3.High low temperature impact toughness. | ||||

| Applications | For making wheel gear; worm gear; plastic mould; the oil seal of steamship andgasoline set etc. | |||

| Sizes | Round bar | Diameter(mm) | Length(mm) | |

| 20~800 | 3000~5800 | |||

| Plate | Thickness(mm) | Width(mm) | Length(mm) | |

| Max:800 | 205~800 | 2000~4000 | ||

| The above is our regular size, We also can provide customized sizes! | ||||

| Packing | seaworthy packing; 20ft: GW:17.5T; (5.80mX2.13mX2.18m,) 40ft: GW:22T; (11.8mX2.13mX2.18m,) | |||

| Price | The price will change according to the weight of the steel you need. | |||

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

Special steel and there is no uniform definition of the concept of special steel is generally considered to have a special chemical composition (alloying), using a special production process, with a special organization and performance to meet the special needs of the steel type. Compared with ordinary steel, special steel has a higher strength and toughness, physical properties, chemical properties, biocompatibility and process performance.

China and Japan, the EU definition of special steel closer, into the special steel quality carbon steel, alloy steel, high alloy steel (alloying elements greater than 10%) three categories, including steel and high-alloy special steel production accounted for 70%. The main advantages of special steel carbon structural steel, carbon tool steel, carbon spring steel, alloy spring steel, alloy steel, ball bearing steel, alloy tool steel, high alloy tool steel, high speed tool steel, stainless steel, heat-resistant steel , and high-temperature alloys, precision alloy, electric alloy. There are nearly 2,000 special steel grades, about 50,000 varieties and specifications in the world currently. In addition to a wide range of special steel outside, in the specification with ordinary steel also showed different characteristics. In addition to plates, tubes, wire, strip, rods and profiles outside, as well as composite materials, surface alloying material, surface treatment material, forging materials, precision casting, powder metallurgy products.

- Q: What are the main characteristics of high-speed steel?

- High-speed steel is known for its exceptional hardness, toughness, and heat resistance. It can maintain its hardness even at high temperatures, making it ideal for cutting tools and machining applications. Additionally, high-speed steel has excellent wear resistance, allowing it to withstand heavy usage and prolong tool life. It also has good machinability and can be easily shaped into various cutting tools.

- Q: How does stainless steel contribute to the production of medical implants?

- Stainless steel contributes to the production of medical implants primarily due to its exceptional properties such as corrosion resistance, high strength, biocompatibility, and ease of sterilization. These qualities make stainless steel an ideal material for manufacturing various medical implants like joint replacements, bone plates, screws, and dental implants.

- Q: How is high-strength alloy steel used in the production of structural components?

- High-strength alloy steel is commonly used in the production of structural components due to its exceptional strength-to-weight ratio. It provides superior tensile strength and toughness, making it suitable for supporting heavy loads and withstanding high stress and impact. This steel is often used in the construction of buildings, bridges, and other infrastructure, as well as in the manufacturing of machinery and vehicles. Its application helps enhance structural integrity, durability, and safety while minimizing the weight and material requirements of these components.

- Q: What are the main characteristics of corrosion-resistant steel?

- Stainless steel, also referred to as corrosion-resistant steel, possesses distinct qualities that render it highly resistant to corrosion. Below are the primary attributes of this type of steel: 1. Exceptional resistance to corrosion: An essential feature of corrosion-resistant steel is its capacity to withstand corrosion. This is achieved through the addition of specific alloying elements, namely chromium, nickel, and molybdenum, which generate a protective layer on the steel's surface. This layer, known as the passive layer, prevents the steel from coming into contact with corrosive substances, including moisture, chemicals, and acids. 2. Superb durability: Corrosion-resistant steel boasts remarkable durability, making it suitable for diverse applications in harsh environments. It can endure extreme temperatures, high humidity levels, and corrosive chemicals without deteriorating or compromising its structural integrity. This durability ensures that structures constructed from corrosion-resistant steel enjoy an extended service life, thereby reducing the need for frequent maintenance and replacements. 3. Aesthetically pleasing: In addition to its functionality, corrosion-resistant steel offers aesthetic appeal. Its smooth and polished surface bestows it with a visually pleasing appearance, rendering it a popular choice for architectural applications, interior design, and decorative elements. The ability to maintain its appearance over time, without rusting or discoloration, enhances its desirability in both industrial and residential settings. 4. High strength: Renowned for its strength and toughness, corrosion-resistant steel retains its mechanical properties even in corrosive environments. Consequently, it can withstand heavy loads, impacts, and other external forces, making it suitable for applications where structural integrity and safety are paramount. Examples include bridges, buildings, marine equipment, and automotive components. 5. Versatility: Corrosion-resistant steel exhibits versatility in terms of its applications. It can be easily fabricated, welded, machined, and formed into various shapes and sizes, thereby allowing for customization and adaptability. This versatility renders it ideal for a wide array of industries, encompassing construction, aerospace, automotive, chemical processing, and marine. 6. Hygienic properties: Another crucial characteristic of corrosion-resistant steel lies in its hygienic properties. Its non-porous surface impedes the growth of bacteria, making it suitable for applications in the food and beverage industry, healthcare facilities, and pharmaceutical manufacturing. Furthermore, its ease of cleaning and maintenance further bolsters its hygiene standards. In summary, corrosion-resistant steel seamlessly combines exceptional resistance to corrosion with durability, strength, versatility, and aesthetic appeal. These characteristics render it a dependable and cost-effective material for various industries, ensuring long-term performance and protection against the detrimental effects of corrosion.

- Q: Can special steel be used for making electrical components?

- Indeed, electrical components can indeed be crafted using special steel. Special steel denotes a collection of steels boasting distinct properties and features that render them fitting for diverse uses, including electrical components. These steels are frequently tailored to possess exceptional electrical conductivity, minimal electrical resistance, commendable magnetic traits, and outstanding heat endurance. They are commonly employed in electrical engineering scenarios where utmost performance and dependability are indispensable, such as the production of transformers, motors, generators, and electrical transmission systems. Furthermore, special steel can also furnish protection against corrosion and elevated temperatures, thereby augmenting its aptness for the manufacturing of electrical components.

- Q: What are the applications of special steel in aerospace engineering?

- The aerospace industry heavily relies on special steels for their distinct characteristics and capabilities. These steels are specifically crafted to meet the demanding needs of aerospace engineering, where utmost importance is placed on strength, resistance to corrosion, and tolerance to extreme temperatures. Here are some notable applications of special steel in aerospace engineering: 1. Aircraft engine components: Stainless steels and other special steels are extensively used in the production of aircraft engine components. These steels offer unparalleled strength, resistance to corrosion, and durability at high temperatures, making them perfect for critical parts like turbine blades, compressor discs, and shafts. 2. Landing gear systems: The landing gear of an aircraft undergoes significant stress and impact during takeoff, landing, and taxiing. To withstand these forces, special steels with remarkable strength, toughness, and resistance to fatigue are utilized in the manufacturing of landing gear components such as struts, axles, and shock absorbers. 3. Structural components: Aerospace structures must endure dynamic loads, vibrations, and extreme environmental conditions. Various structural components like wings, fuselage frames, and support structures employ special steels, particularly high-strength low-alloy (HSLA) steels. These steels offer exceptional strength-to-weight ratios, ensuring structural integrity while minimizing weight. 4. Fasteners: Special steel fasteners, including bolts, screws, and rivets, play a crucial role in joining different components in aerospace applications. These fasteners are typically made from high-strength steels, providing exceptional tensile and shear strength, as well as resistance to corrosion, to ensure secure and reliable connections. 5. Fuel system components: Special steels with high resistance to corrosion, such as stainless steels, are utilized in the construction of fuel system components like tanks, pipes, and valves. These steels prevent fuel leakage and maintain the system's integrity, even in harsh environments. 6. Electrical connectors: Aerospace electrical systems necessitate reliable and efficient electrical connectors. Special steels, often possessing high electrical conductivity and resistance to corrosion, are employed in the manufacturing of connectors, guaranteeing optimal performance and longevity. In conclusion, the outstanding properties of special steels make them indispensable in aerospace engineering. Whether it is for critical engine components, landing gear systems, structural applications, fasteners, fuel systems, or electrical connectors, these steels provide the necessary strength, resistance to corrosion, and stability in extreme temperatures, ensuring safe and efficient aircraft operation.

- Q: How does special steel resist thermal fatigue?

- Special steel is able to resist thermal fatigue due to its unique composition and properties. Thermal fatigue occurs when a material is subjected to repeated heating and cooling cycles, leading to the formation of cracks and eventual failure of the material. Special steel is specifically designed to withstand extreme temperature changes. It has a high melting point and excellent thermal conductivity, which allows it to efficiently dissipate heat and minimize thermal stress. Additionally, the steel is often alloyed with elements such as chromium, nickel, and molybdenum, which enhance its resistance to thermal fatigue. The alloying elements in special steel form a protective layer that acts as a barrier against oxidation and corrosion. This protective layer prevents the formation of cracks and improves the steel's ability to withstand thermal cycling. Furthermore, the alloying elements improve the steel's structural integrity by promoting the formation of fine and evenly dispersed microstructures. This enhances the steel's toughness and resistance to cracking. Moreover, special steel undergoes various heat treatment processes to further enhance its resistance to thermal fatigue. These processes involve controlled heating and cooling cycles, which refine the microstructure of the steel and make it more resistant to deformation and cracking. The heat treatment also helps in relieving any residual stresses that may have been induced during the manufacturing process. In summary, special steel resists thermal fatigue through its unique composition, alloying elements, and heat treatment processes. Its high melting point, excellent thermal conductivity, and protective layer against oxidation and corrosion make it highly resistant to thermal cycling. The refined microstructure and relieved residual stresses further enhance its ability to withstand repeated heating and cooling cycles without failure.

- Q: What are the common alloying elements in special steel?

- The common alloying elements in special steel are chromium, manganese, molybdenum, nickel, and vanadium.

- Q: How does special steel contribute to the aerospace racing aftermarket industry?

- Special steel is an essential component in the aerospace racing aftermarket industry as it plays a significant role in enhancing the performance, durability, and safety of aircraft and racing vehicles. Firstly, special steel is used in the manufacturing of critical engine components, such as turbine blades, compressor discs, and shafts. These components must withstand extreme temperatures, pressures, and mechanical stress during operation. Special steel alloys, such as nickel-based superalloys, provide excellent heat resistance, high strength, and exceptional corrosion resistance, ensuring peak performance and reliability of the engine systems. Moreover, special steel is vital in the construction of airframe structures. The lightweight but high-strength properties of special steel alloys, such as titanium alloys, are crucial in reducing the overall weight of aircraft and racing vehicles. This weight reduction contributes to improved fuel efficiency, increased speed, and better handling capabilities, making it an indispensable material in the aerospace racing aftermarket. In addition, special steel is utilized in the production of landing gear systems, which are crucial for safe takeoffs, landings, and overall maneuverability. The landing gear must endure immense forces and shock loads during these operations. Special steel alloys, like chromium-molybdenum steel, offer exceptional toughness, fatigue resistance, and impact strength, ensuring the landing gear's reliability and longevity. Furthermore, special steel plays a crucial role in the manufacturing of aerospace racing aftermarket components, such as fasteners, bearings, and gears. These components require high strength, wear resistance, and dimensional stability to withstand the demanding conditions of racing and provide optimal performance. Special steel alloys, including stainless steel and tool steel, possess these desirable properties, ensuring the longevity and reliability of these crucial components. Overall, special steel's contribution to the aerospace racing aftermarket industry cannot be overstated. Its exceptional properties, including high strength, heat resistance, corrosion resistance, and fatigue resistance, enable the production of reliable, efficient, and high-performance aircraft and racing vehicles. Without special steel, the aerospace racing aftermarket industry would be unable to achieve the level of advanced technology, speed, and safety that it currently enjoys.

- Q: How does special steel contribute to the strength of structures?

- Special steel contributes to the strength of structures by providing enhanced properties such as high tensile strength, durability, and resistance to corrosion. This type of steel is specifically engineered to withstand heavy loads, extreme conditions, and harsh environments. Its superior strength allows for the construction of structures that can support more weight, withstand greater pressures, and resist deformation. Whether used in buildings, bridges, or machinery, special steel plays a vital role in ensuring the structural integrity and longevity of various constructions.

Send your message to us

Din 1.7131 16mncr15 Alloy Structure Steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords