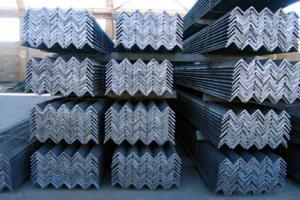

Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc mild angle steel |

Grade | Q235, Q345, SS400, A36, S235JR,S355JR, ST37-2,ST52, etc |

Equal Angle steel | Type: 2.5#-20# Size: 25-200mm Thickness: 3.0-20mm Weight: 0.597-71.168kg/m |

Unequal Angle steel | Type: 2.5/1.6-20/12.5 Long Side: 25-200mm Short Side: 16-125mm Thickness: 3.0-18mm Weight: 1.687-43.588kg/m |

Length | 5.8-12.0m OR according to client's request |

Element Contect | C<0.22% Si:<0.16% Mn: 0.30—0.65% P<0.060% S<0.060% |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What is the maximum allowable torsional buckling stress for a steel angle?

- The torsional buckling stress limit for a steel angle is determined by multiple factors, including the steel's material properties, the angle's geometry, and the applied load conditions. Torsional buckling occurs when a member twists due to torque, leading to instability and potential failure. To prevent this, design codes and standards offer guidelines and formulas for determining the maximum allowable stress. One example is the American Institute of Steel Construction (AISC), which provides a formula in their Steel Construction Manual for calculating torsional buckling stress. This formula considers the angle's section properties, such as the moment of inertia and radius of gyration, as well as the member's slenderness ratio and effective length. It's important to note that the maximum allowable torsional buckling stress varies based on specific design requirements and safety factors applied during the design process. Therefore, consulting relevant design codes and a structural engineer is crucial to determine the specific maximum allowable torsional buckling stress for a given steel angle in a particular design scenario.

- Q: Can steel angles be used in storage rack systems?

- Yes, steel angles can be used in storage rack systems. Steel angles provide strength and stability, making them suitable for supporting heavy loads in storage racks. They can be used to create the framework and support beams in the rack system, ensuring durability and safety.

- Q: How do you prevent corrosion between steel angles and other materials?

- There are several effective measures that can be taken to prevent corrosion between steel angles and other materials: 1. To create a barrier between the steel and surrounding materials, protective coatings such as paint, epoxy, or galvanization can be applied. This prevents direct contact and reduces the risk of corrosion. 2. Insulating materials like rubber or plastic pads or sleeves can be used to separate the steel angles from other materials. This prevents direct contact and minimizes the chances of corrosion. 3. A cathodic protection mechanism can be established by installing sacrificial anodes or using impressed current systems. This creates an electrical current that counteracts the corrosion process, protecting the steel angles. 4. Regular inspection and maintenance of the steel angles are crucial to promptly identify any signs of corrosion and take appropriate actions. This includes cleaning the surfaces, repairing damaged coatings, and replacing corroded parts. 5. Proper drainage is essential to prevent moisture accumulation around the steel angles, which can accelerate corrosion. Designing and installing drainage systems correctly can prevent water or corrosive substances from pooling around the steel angles. 6. If the steel angles are exposed to chemicals or corrosive substances, it is important to choose materials that are resistant to corrosion. This may involve using stainless steel or other corrosion-resistant alloys to withstand exposure to specific chemicals. By implementing a combination of protective coatings, insulation, cathodic protection, regular maintenance, proper drainage, and material selection, corrosion between steel angles and other materials can be effectively prevented. This ensures the longevity and structural integrity of the steel angles.

- Q: Can steel angles be used for support columns in building construction?

- Steel angles can indeed be utilized as support columns in building construction. Their strength, durability, and versatility render them frequently employed in construction. When employed as columns, they offer exceptional support and stability, particularly in structures of small to medium size. Furthermore, steel angles can be easily fabricated and tailored to satisfy precise design criteria. They also boast resistance against fire, corrosion, and pests, signifying their dependability as support columns in building construction.

- Q: What is the maximum deflection allowed for a steel angle?

- The maximum deflection allowed for a steel angle depends on various factors such as the size, shape, and type of steel angle being used, as well as the specific application and design requirements. The deflection limit is typically determined based on engineering standards and codes, which outline the maximum acceptable deflection to ensure structural integrity and safety. In general, steel angles are designed to withstand different loads and stresses, and their allowable deflection is determined based on these factors. Engineers calculate the maximum allowable deflection to ensure that the angle can safely support the applied loads without experiencing excessive deformation or failure. To determine the maximum deflection allowed for a specific steel angle, one needs to refer to the design standards and specifications provided by professional engineering organizations, such as the American Institute of Steel Construction (AISC) or relevant building codes. These documents outline the maximum allowable deflection limits based on the specific parameters of the steel angle, such as its dimensions, material properties, and intended use. It is crucial to consult the appropriate design standards and codes to ensure compliance with safety regulations and to guarantee the structural integrity of the steel angle in its intended application.

- Q: What is the minimum radius for a curved steel angle beam?

- The minimum radius for a curved steel angle beam depends on various factors such as the material thickness, type of steel, and the specific design requirements. However, there are generally accepted guidelines to follow when considering the minimum radius for a curved steel angle beam. As a rule of thumb, the minimum radius for a curved steel angle beam is typically determined by the bending capacity of the steel material being used. The bending capacity is influenced by the yield strength, tensile strength, and the section properties of the steel angle beam. To calculate the minimum radius, it is necessary to consider the bending stress induced in the steel angle beam. The bending stress is a function of the applied load, the curvature radius, and the section properties of the beam. By ensuring that the bending stress does not exceed the allowable stress limits of the steel material, a safe minimum radius can be established. It is important to consult relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual or the Eurocode, for specific guidelines and requirements regarding minimum radii for curved steel angle beams. These codes provide comprehensive information on the design and fabrication of curved steel members, including minimum radius limitations. Additionally, it is recommended to seek the assistance of a qualified structural engineer or a steel fabrication specialist who can perform the necessary calculations and analyses based on the specific project requirements.

- Q: Can steel angles be used as lintels or supports for openings?

- Yes, steel angles can be used as lintels or supports for openings. Steel angles are commonly used in construction as structural elements due to their strength and durability. When used as lintels or supports for openings such as doors and windows, steel angles provide the necessary structural support to bear the load above the opening. They can be installed horizontally above the opening, with one leg of the angle bearing against the wall on either side. The load from the structure above is transferred to the steel angle, which in turn distributes the load to the surrounding walls. Steel angles are a popular choice for lintels and supports due to their high load-bearing capacity and resistance to bending and twisting forces.

- Q: What is the thickness of the national standard 8# angle steel? Thank you

- Test method: to test the chemical composition, test methods commonly used standards GB223, JISG1211-1215, BS1837, BS, C, f 19 manual is 22536.

- Q: What are the limitations of using steel angles in highly corrosive or chemical environments?

- The limitations of using steel angles in highly corrosive or chemical environments include the risk of accelerated corrosion and degradation of the steel material. Steel angles are susceptible to corrosion when exposed to corrosive substances or environments, which can weaken the structural integrity and durability of the angles over time. Additionally, certain chemicals may react with the steel, leading to chemical corrosion and further deterioration. To mitigate these limitations, alternative corrosion-resistant materials such as stainless steel or non-metallic composites should be considered for use in highly corrosive or chemical environments.

- Q: How do you calculate the shear strength of a steel angle?

- To calculate the shear strength of a steel angle, you need to consider the properties of the material and the geometry of the angle. The shear strength is a measure of the maximum load that the angle can withstand before it fails under shear stress. First, you need to determine the cross-sectional area of the steel angle. This can be calculated by multiplying the thickness of the angle by the length of one side. For example, if the angle has a thickness of 0.25 inches and a length of 4 inches, the cross-sectional area would be 1 square inch (0.25 inches x 4 inches). Next, you need to determine the shear stress that the angle can withstand. This is typically provided by the manufacturer and is given as a maximum value in pounds per square inch (psi) or megapascals (MPa). For example, let's say the shear stress is given as 30,000 psi. To calculate the shear strength, you simply multiply the cross-sectional area by the shear stress. Using the example values, the shear strength would be 1 square inch x 30,000 psi = 30,000 pounds. It is important to note that this calculation assumes the angle is loaded in a single shear plane and that the material is homogenous and isotropic. In real-world applications, there may be additional factors to consider, such as the presence of holes, welds, or other stress concentrations. In these cases, more complex calculations or testing may be required to determine the shear strength accurately.

Send your message to us

Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords