Half Round Aluminum Extrusion Profiles - Aluminum Sheet and Cold Rolled Plate Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

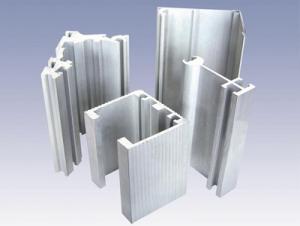

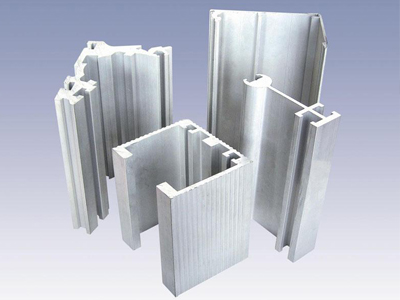

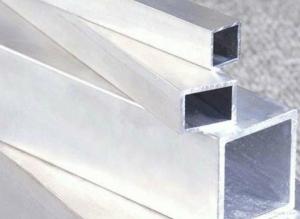

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

1100 grade and other else grades,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, there are several methods you can use depending on the desired outcome and the tools you have available. Here are three common techniques: 1. Cutting with a hacksaw or miter saw: This is the most basic and accessible method. Using a hacksaw or a miter saw with an aluminum cutting blade, mark the desired length on the profile and carefully cut through it. Ensure you have a secure grip on the profile and make slow, steady cuts to avoid excessive vibration or the blade getting stuck. 2. Using a power saw or circular saw: For larger or thicker aluminum profiles, a power saw or circular saw with a specialized aluminum cutting blade will make the job faster and easier. Measure and mark the desired length on the profile, then secure it firmly in place. Using the power saw, slowly and steadily cut through the profile, ensuring you have a firm grip and maintaining control throughout the process. 3. Shaping with a file or grinder: Once the profile is cut to the desired length, you may need to shape or smooth the edges. This can be done using a file or grinder with an aluminum grinding wheel or sanding disc. Carefully work the file or grinder along the edges, shaping or smoothing them as needed. Take care not to apply too much pressure, as aluminum can heat up quickly and may distort or become damaged. Remember to wear appropriate safety gear, such as gloves and eye protection, when working with aluminum profiles. Additionally, it's always a good idea to practice on scrap pieces first to familiarize yourself with the techniques and tools before working on the final product.

- Q: What are the different types of surface protection for aluminum profiles?

- There are several types of surface protection for aluminum profiles, including anodizing, powder coating, painting, and laminating. Anodizing involves creating a durable oxide layer on the surface of the aluminum, providing corrosion and wear resistance. Powder coating involves applying a dry powder to the surface and then curing it with heat, creating a tough and decorative finish. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminating involves applying a layer of protective film or sheet to the surface, offering scratch resistance and added durability.

- Q: How do aluminum profiles perform in vibration isolation applications?

- Aluminum profiles are commonly used in vibration isolation applications due to their excellent mechanical properties. They exhibit high stiffness, durability, and damping characteristics, which help in effectively reducing vibrations. Additionally, their lightweight nature allows for easy installation and portability. Overall, aluminum profiles perform well in vibration isolation applications, providing reliable and efficient solutions.

- Q: Are aluminum profiles suitable for cleanroom partitions?

- Yes, aluminum profiles are often suitable for cleanroom partitions. Aluminum is a lightweight and durable material that is resistant to corrosion, making it a popular choice for cleanroom applications. It is easy to clean and maintain, which is crucial in maintaining the cleanliness and sterility of a cleanroom environment. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility in designing cleanroom partitions to meet specific requirements. The versatility of aluminum profiles also enables the integration of various features such as doors, windows, and pass-through chambers, further enhancing the functionality of cleanroom partitions. Overall, with their excellent properties and adaptability, aluminum profiles are a reliable and suitable choice for cleanroom partitions.

- Q: This question asks for a list of various roofing systems that incorporate the use of aluminum profiles.

- <p>Aluminum profiles are used in several types of roofing systems for their durability, lightweight, and corrosion resistance. Some common types include: 1. Standing Seam Roofing: Known for its sleek, clean appearance and watertight properties. 2. Aluminum Shingle Roofing: Mimics the look of traditional shingles but with the benefits of aluminum. 3. Metal Tile Roofing: Offers the aesthetic of clay or slate tiles with the strength of aluminum. 4. Aluminum Panel Roofing: Consists of large panels that cover a broad area quickly and efficiently. 5. Aluminum Shake Roofing: Provides a rustic look similar to wooden shakes but with the longevity of aluminum. Each system has its own advantages and is chosen based on factors like design, cost, and environmental conditions.</p>

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- Curvature:1. longitudinal bending: the profile is placed on the platform, and when the weight is stable, the maximum gap between the bottom of the profile and the platform is measured along the length of the profile, that is, the longitudinal curvatureThe 2. longitudinal wave degree (or bend): the section on the platform, to achieve stability by self, the ruler will be 300mm long (or flat on the surface of the profile cutter) waves or hard along the length direction of a profile, profile measurement and rule (or ruler knife) between the maximum gap value that is, longitudinal wave degree (or bend).

- Q: What are the color options available for aluminum profiles?

- The color options available for aluminum profiles are vast and can be customized to suit individual preferences and design needs. Some common color options include natural aluminum (silver), white, black, bronze, and various shades of grey. Additionally, it is possible to select custom colors by applying powder coating or anodizing processes to the aluminum profiles. These processes allow for a wide range of colors to be achieved, including vibrant hues and metallic finishes. Ultimately, the color options for aluminum profiles are extensive, enabling individuals to find the perfect match for their specific project or aesthetic requirements.

- Q: What are the different machining options available for aluminum profiles?

- There are several machining options available for aluminum profiles, including milling, drilling, tapping, turning, and sawing. These processes can be used to create various shapes, sizes, and features on the aluminum profiles, allowing for customization and precise fabrication. Additionally, advanced techniques such as CNC machining and laser cutting can also be employed for more complex and intricate designs.

- Q: Regarding the wall thickness of aluminum alloy profiles, are there any standards in the country?

- < technical specification for glass curtain wall JGJ102-2003> open section bar is not less than 3.0mm. For example, the beams are mostly open and closed at one end with a cover plate. Closed profiles such as stand up, mostly closed type, not less than 2.5mm, these are only the minimum requirements for wall thickness, but also in accordance with the calculation of the book in the calculation of the wall thickness.

- Q: I have a product in the aluminum above the oxidation of 20 through the hole, that is so, good heat dissipation, I do not know, right, before oxidation, punching OK?

- Of course, the heat conductivity of metals is usually worse after oxidation.Near room temperature:Thermal conductivity of alumina 10W/m = KAluminum thermal conductivity 237W/m = KBut you seem to have another problem hereThe purpose of opening the hole is to use Kong Zengda radiation area to enhance heat dissipation?This oxidation before and after oxidation play no difference.

Send your message to us

Half Round Aluminum Extrusion Profiles - Aluminum Sheet and Cold Rolled Plate Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords