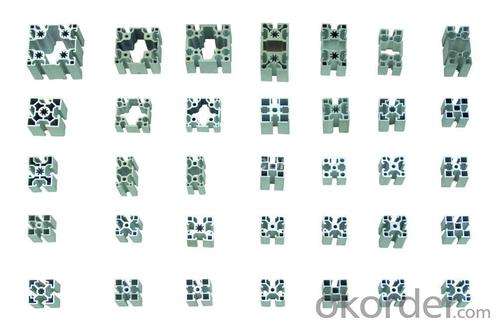

Aluminum Alloy Profiles - Slot Aluminium Profiles Extrusions

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with concrete or masonry?

- To minimize the occurrence of galvanic corrosion when combining aluminum profiles with concrete or masonry, several precautions can be taken: 1. Opt for suitable materials: Choose aluminum profiles specifically designed for use in conjunction with concrete or masonry. These profiles often come with coatings or treatments that offer protection against corrosion. 2. Insulate the aluminum profiles: Create an insulating barrier between the aluminum profiles and the concrete or masonry surfaces. This can be achieved by utilizing non-conductive materials like gaskets, rubber pads, or coatings. 3. Avoid direct contact: Whenever feasible, try to reduce direct contact between the aluminum profiles and the concrete or masonry. This can be accomplished by utilizing spacers or other methods of separation to establish a gap between the two materials. 4. Ensure proper installation: Follow the manufacturer's guidelines and recommendations to correctly install the aluminum profiles. This includes using appropriate fasteners and techniques to secure the profiles while preserving the insulation and protective measures. 5. Regular upkeep: Conduct regular inspections of the aluminum profiles and the surrounding concrete or masonry to detect any signs of corrosion or damage. Promptly address any issues to prevent further deterioration. By adhering to these preventive measures, the risk of galvanic corrosion between aluminum profiles and concrete or masonry can be significantly reduced, thereby extending the lifespan and performance of the materials involved.

- Q: This question asks if it is possible to recycle aluminum profiles in a simple and effective manner.

- <p>Yes, aluminum profiles can be recycled easily and efficiently. Aluminum is one of the most recycled materials in the world due to its non-toxic nature and the energy efficiency of the recycling process. Recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it a highly sustainable material. The recycling process involves melting the aluminum, which is a relatively simple and cost-effective procedure compared to many other materials. This makes aluminum an ideal material for sustainable manufacturing and waste reduction strategies.</p>

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Yes, aluminum profiles are generally suitable for use in chemical processing environments. Aluminum has excellent corrosion resistance properties and can withstand various chemicals, acids, and bases. Additionally, aluminum profiles can be further enhanced with protective coatings or anodization to provide even greater resistance to chemical exposure. However, the suitability may depend on the specific chemicals and conditions involved, so it is important to consult with experts or suppliers to ensure the best choice of aluminum profiles for a particular chemical processing environment.

- Q: What are the different powder coating options for aluminum profiles?

- There are several different powder coating options available for aluminum profiles, each offering unique advantages and characteristics. 1. Polyester powder coating: This is the most common and economical option for aluminum profiles. It provides excellent UV resistance and color retention, making it suitable for both indoor and outdoor applications. Polyester powder coatings are available in a wide range of colors and finishes, including matte, glossy, and textured. 2. Epoxy powder coating: Epoxy coatings offer excellent adhesion and corrosion resistance, making them suitable for demanding environments such as marine or industrial applications. They have good chemical resistance and are often used as a primer before applying a topcoat for added durability. 3. Polyurethane powder coating: Polyurethane coatings provide exceptional durability and resistance to abrasion, making them ideal for high-traffic areas or surfaces that are prone to wear and tear. They offer excellent color retention and gloss retention, ensuring a long-lasting finish. 4. Fluoropolymer powder coating: Fluoropolymer coatings, such as PVDF (polyvinylidene fluoride), are known for their outstanding resistance to chemicals, UV radiation, and weathering. They are highly durable and provide excellent color retention, making them suitable for architectural applications where long-term performance is essential. 5. Hybrid powder coating: Hybrid coatings are a combination of epoxy and polyester resins, offering a balance of excellent adhesion and color retention. They provide good weather resistance and are often used in general-purpose applications where cost-effectiveness is a priority. It's important to consider the specific requirements of your project when choosing a powder coating option for aluminum profiles. Factors such as intended use, environmental conditions, and desired aesthetics will help determine the most suitable option for achieving the desired performance and appearance.

- Q: Are aluminum profiles resistant to chemicals or solvents?

- Yes, aluminum profiles are generally resistant to chemicals and solvents. Due to their natural oxide layer, they exhibit good corrosion resistance and can withstand exposure to many common chemicals and solvents without significant degradation or damage. However, it is important to note that the specific resistance may vary depending on the type of chemical or solvent involved, concentration, temperature, and exposure duration.

- Q: How do aluminum profiles perform in terms of sound insulation?

- Compared to materials like wood or uPVC, aluminum profiles generally do not have good sound insulation properties. This is because aluminum is lightweight and thin, allowing sound waves to easily pass through. Furthermore, aluminum profiles often have a hollow structure, which further reduces their ability to block or absorb sound. It is important to consider that the overall sound insulation performance of a window or door system depends on various factors. These include the thickness of the glass, the quality of the seals, and the installation method. To improve the sound insulation capabilities of aluminum profiles, manufacturers may incorporate additional features such as double or triple glazing, laminated glass, or acoustic seals. In conclusion, while aluminum profiles alone may not offer optimal sound insulation, their performance can be enhanced by combining them with other elements. If sound insulation is a major concern, it is advisable to explore alternative materials that inherently provide better sound insulation properties.

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally have good creep resistance due to their high strength and stiffness. They can withstand sustained loads and high temperatures over a long period of time without significant deformation. However, the creep resistance of aluminum profiles may vary depending on the specific alloy and manufacturing process used.

- Q: Explain if aluminum profiles can be utilized in constructing energy-efficient building systems and if so, how they contribute to energy efficiency.

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight yet strong, which reduces the energy required for construction. Aluminum profiles also have excellent thermal conductivity, allowing them to be used in double-glazed windows and doors, improving insulation and reducing heat loss. Additionally, aluminum can be easily recycled, reducing the energy needed for new materials. Their high reflectivity can also help in reducing heat absorption, further contributing to energy efficiency.</p>

- Q: Why should aluminum surface treatment process?

- In order to strengthen the performance of aluminum material.Anodizing, passivation, electroplating, spraying, and some other surface treatment processes are designed to "resist corrosion" and allow aluminum to last longer without oxidation.

- Q: I would like to know where Urumqi has industrial aluminum profiles, such as 3030, 4040, 3060 aluminum, etc., note that industrial aluminum, not doors and windows, aluminum profiles, the difference between the two very large!

- And shares in the east railway station there, the east railway station and then go one Station Road (near the North Main Road) can see.

Send your message to us

Aluminum Alloy Profiles - Slot Aluminium Profiles Extrusions

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords