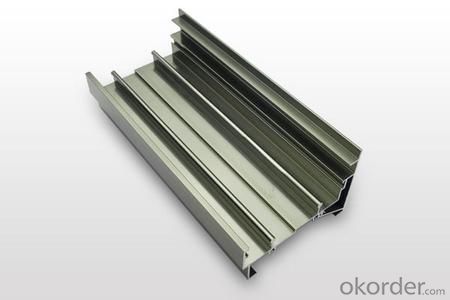

Aluminum Door Profiles for Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: What tests do the aluminum profiles used in the curtain wall project do?

- Tensile properties, hardness, coating thickness

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: What are the different surface patterns or textures available for aluminum profiles?

- There are various surface patterns or textures available for aluminum profiles, including smooth, brushed, anodized, textured, embossed, and patterned finishes. These different finishes offer a range of aesthetic and functional options, allowing for customization and versatility in various applications.

- Q: This question asks about the various uses of aluminum profiles in the construction of buildings.

- <p>Aluminum profiles have a wide range of applications in building construction due to their strength, durability, and lightweight properties. They are used in window and door frames, curtain walls, and structural glazing systems for their high strength-to-weight ratio and resistance to corrosion. Additionally, aluminum profiles are utilized in the construction of balconies, handrails, and stairways for their ability to withstand harsh weather conditions. They are also employed in the fabrication of modular building systems and prefabricated components, offering ease of assembly and design flexibility. Furthermore, aluminum profiles are used in the construction of solar panel mounting systems and facades due to their thermal conductivity and ability to support heavy loads.</p>

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: How is the tonnage of aluminum profile extrusion machine calculated? Do you have any formulas? For example, 30*60 industrial profiles, the need for a large tonnage of extrusion machine can be done?

- This depends on the section of the rice weight, the length of the required material, as well as extrusion deformation of the profile to consider, but generally to 6 meters out of the standard length, and then according to meters to determine the machine

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Yes, aluminum profiles are suitable for medical equipment and devices. Aluminum offers several advantages such as lightweight, durability, corrosion resistance, and ease of fabrication. These properties make it ideal for medical equipment and devices that require strength, precision, and cleanliness. Additionally, aluminum profiles can be easily sterilized, making them suitable for use in healthcare settings.

- Q: What are the limitations of using aluminum profiles?

- Some limitations of using aluminum profiles include its relatively low strength compared to other metals like steel, making it less suitable for heavy-duty applications. It is also prone to corrosion in certain environments, requiring protective coatings or treatments. Additionally, aluminum profiles may not be as readily available or cost-effective in some regions compared to other materials.

- Q: What are the advantages of using aluminum profiles in the railway industry?

- There are several advantages of using aluminum profiles in the railway industry. Firstly, aluminum profiles are lightweight yet strong. This makes them ideal for use in various railway applications such as train carriages, windows frames, and structural components. The lighter weight of aluminum profiles helps to reduce the overall weight of the train, resulting in lower energy consumption and improved fuel efficiency. It also allows for increased payload capacity, enabling trains to carry more passengers or cargo. Secondly, aluminum profiles have excellent corrosion resistance. Trains are exposed to different weather conditions and environments, including rain, snow, and high humidity. The corrosion resistance of aluminum profiles ensures that they can withstand these conditions without deteriorating or losing their structural integrity. This translates to longer lifespan and reduced maintenance costs for railway operators. Another advantage of using aluminum profiles in the railway industry is their flexibility and versatility. Aluminum can be easily extruded into various shapes and sizes, allowing for customization and design flexibility. This enables manufacturers to create complex and intricate profiles that meet the specific requirements of railway applications. Additionally, aluminum profiles can be easily joined or assembled using various techniques, making them suitable for quick and efficient assembly during train manufacturing or maintenance. Furthermore, aluminum profiles are highly recyclable. With sustainability becoming increasingly important in the railway industry, aluminum's recyclability makes it an environmentally friendly choice. Aluminum can be recycled multiple times without losing its properties, reducing the demand for primary aluminum production and minimizing the environmental impact. Lastly, aluminum profiles offer aesthetic advantages. They can be finished with different coatings or anodized to enhance their appearance and provide additional protection against wear and tear. This allows for the creation of visually appealing train interiors and exteriors, contributing to a positive passenger experience. In conclusion, the advantages of using aluminum profiles in the railway industry include their lightweight yet strong nature, corrosion resistance, flexibility, recyclability, and aesthetic appeal. These benefits make aluminum profiles a preferred choice for various railway applications, contributing to improved performance, reduced costs, and enhanced sustainability in the industry.

- Q: Are aluminum profiles suitable for interior design applications?

- Yes, aluminum profiles are suitable for interior design applications. They are versatile, lightweight, and can be easily customized to fit various designs and purposes. Aluminum profiles offer a modern and sleek aesthetic, and they are commonly used for items such as doors, windows, partitions, furniture, and decorative elements. Additionally, aluminum is durable, corrosion-resistant, and requires minimal maintenance, making it a practical choice for interior design projects.

Send your message to us

Aluminum Door Profiles for Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords