Aluminum Extrusion Profiles Illinois - Electrophoresis Aluminium Profile 6003 Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Electrophoresis Aluminium Profile 6003 Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Electrophoresis Aluminium Profile 6003 Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

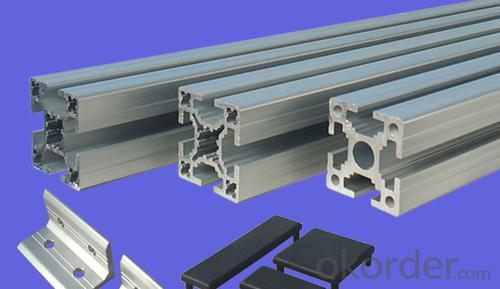

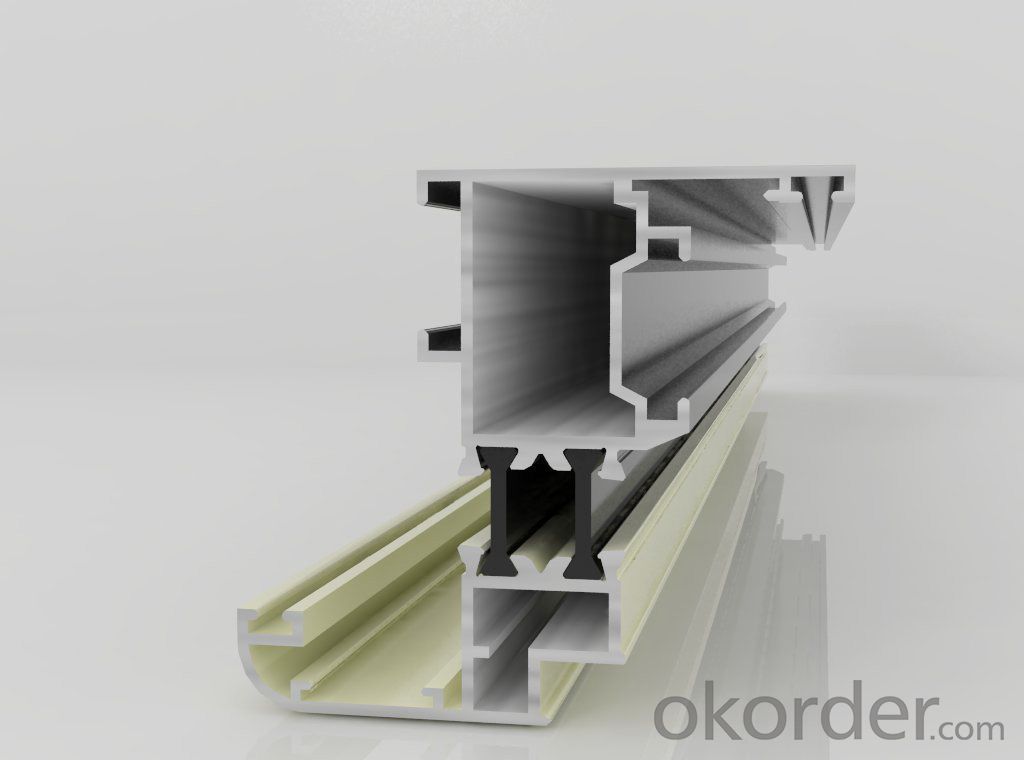

3.Electrophoresis Aluminium Profile 6003 Quality Images:

4.Aluminium Profile for Cars Auto-parts Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Aluminum Alloy rail safety glass balcony design, Aluminum Alloy profiles for what is standard specifications?

- Aluminum alloy profiles are basically no GB non-standard, but the state has special specifications for architectural aluminum profiles, mainly to the thickness of the profiles, materials and so on.Each aluminum alloy profiles manufacturing enterprises are basically similar products, but in specific structure of the discrepancy. But such as the more general series, such as GB 50, 868, and 90, these are basically the same.The 80 series and the 60 series refer to the aluminium alloy profiles with widths of 80 mm and 60 mm.According to the extrusion process, it can be divided into oxidation, electrophoresis, electrostatic powder spraying, fluorocarbon spraying, which means different coating methods. At present, 85% of the consumption in the market is electrostatic powder spraying section, that is colored aluminum section.I have been involved in related work for several years. If you need any help, please contact me.

- Q: What unique considerations or criteria must be met when installing aluminum profiles to ensure they are correctly installed?

- <p>Yes, there are special requirements for installing aluminum profiles correctly. These include ensuring the profiles are of the correct size and specifications for the intended application, proper alignment to maintain structural integrity, and secure fastening to prevent movement or damage. Additionally, it's crucial to follow the manufacturer's guidelines for installation, which may include specific torque settings for screws or bolts, and to consider environmental factors such as temperature and humidity that could affect the profile's performance over time. Proper installation also involves checking for any damage or defects in the profiles before installation and ensuring that all components are compatible with each other.</p>

- Q: Can aluminum profiles be used in modular wall systems?

- Yes, aluminum profiles can be used in modular wall systems. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular walls. They can be easily assembled, disassembled, and reconfigured to meet specific design requirements. Additionally, aluminum profiles offer excellent structural integrity and can accommodate various finishes, such as glass panels or cladding, enhancing the aesthetics of the modular wall system.

- Q: Are aluminum profiles suitable for use as interior finishing materials, specifically for flooring and wall panels?

- <p>Yes, aluminum profiles can be used for interior finishing materials such as flooring and wall panels. They are known for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be used in various designs and styles, making them a popular choice for modern interior design. They also offer the advantage of being recyclable and environmentally friendly.</p>

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: Inquire if aluminum profiles can be recycled locally or regionally and how to find more information about it.

- <p>Yes, aluminum profiles can be recycled both locally and regionally. Recycling aluminum is an efficient process that conserves resources and energy. To find out more about local recycling options for aluminum profiles, you can: 1) Contact your local waste management or recycling center to inquire about their services. 2) Search online for recycling facilities in your region that specialize in aluminum. 3) Reach out to local metal scrapyards, as they often accept aluminum for recycling. 4) Check with local environmental agencies or non-profit organizations focused on recycling for guidance and resources.</p>

- Q: This question asks about the typical applications of aluminum profiles within the field of architectural design.

- <p>Aluminum profiles are commonly used in building design for various structural and aesthetic purposes. They are utilized in curtain walls, window frames, and door systems for their strength and lightweight properties. Additionally, aluminum profiles are employed in the construction of balconies, handrails, and sunshades due to their durability and resistance to corrosion. They are also used in interior design for creating partition walls, ceiling systems, and decorative elements. The versatility of aluminum profiles allows them to be easily adapted to different architectural styles and requirements, making them a popular choice in modern construction.</p>

- Q: Can aluminum profiles be used for medical equipment or devices?

- Yes, aluminum profiles can be used for medical equipment or devices. Aluminum is a lightweight and durable material that is commonly used in the manufacturing of various medical devices such as wheelchairs, surgical instruments, diagnostic equipment, and prosthetics. Its corrosion resistance, strength, and versatility make it suitable for a wide range of medical applications. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, making them a popular choice in the medical industry.

- Q: How do you ensure proper electrical grounding with aluminum profiles?

- To ensure proper electrical grounding with aluminum profiles, there are a few key steps that need to be followed. Firstly, it is important to ensure that all aluminum profiles are clean and free from any dirt, dust, or oxidation. This can be achieved by using a suitable cleaning agent or solvent to remove any contaminants that may hinder the grounding process. Next, proper electrical grounding can be achieved by using conductive hardware such as grounding clips or brackets specifically designed for aluminum profiles. These hardware components should be securely attached to the aluminum profiles, ensuring a reliable electrical connection. Additionally, it is crucial to establish a solid electrical connection between the aluminum profiles and the grounding system. This can be achieved by using copper or aluminum grounding conductors that are properly sized and securely connected to both the aluminum profiles and the grounding system. Furthermore, it is important to regularly inspect the grounding system to ensure its effectiveness. This can involve checking for any loose connections, signs of corrosion, or damage to the grounding conductors. Any issues should be promptly addressed and repaired to maintain proper electrical grounding. Lastly, it is recommended to consult with a qualified electrician or engineer who specializes in electrical grounding when working with aluminum profiles. They can provide specific guidance and ensure compliance with relevant electrical codes and standards to ensure proper and safe electrical grounding.

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Aluminum Extrusion Profiles Illinois - Electrophoresis Aluminium Profile 6003 Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords