Structural Aluminum Profiles for Industrial Material

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile for Industrial Material Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Industrial Material :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

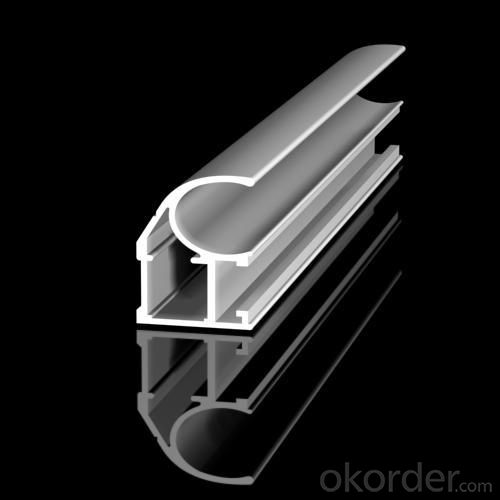

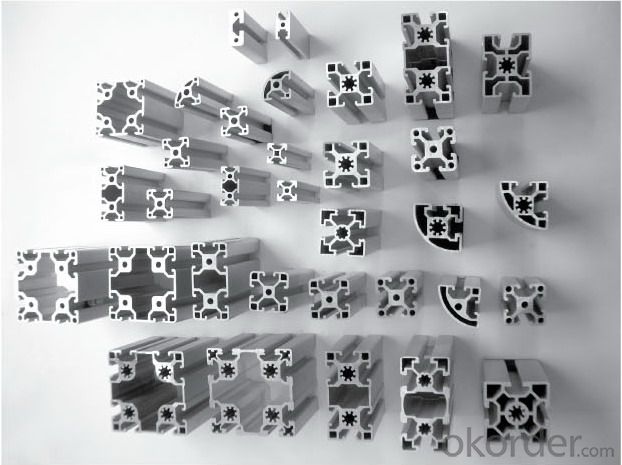

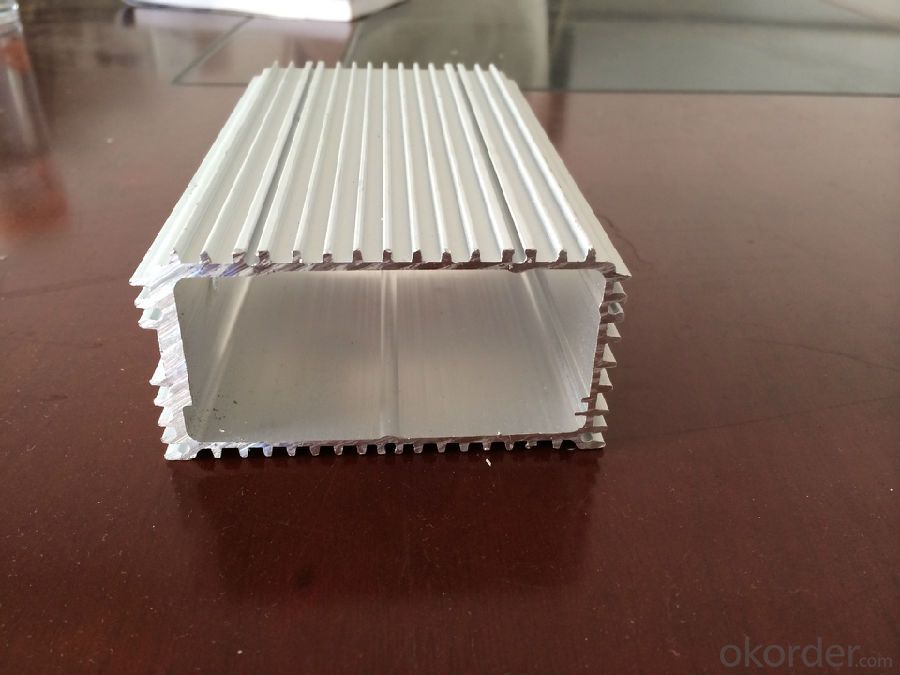

3.Aluminium Profile for Industrial Material Images:

4.Aluminium Profile for Industrial Material Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- Aluminum oxide brand and aluminum panel process and process, please

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or ceilings.

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings due to their strength, durability, and lightweight properties. They offer design flexibility, are easy to install, and can be used in conjunction with various materials like glass or fabric. Additionally, aluminum profiles are resistant to corrosion and require minimal maintenance, making them a popular choice for both residential and commercial applications.</p>

- Q: Can aluminum profiles be used for shopfitting and retail displays?

- Yes, aluminum profiles can be used for shopfitting and retail displays. They are lightweight, durable, and versatile, making them ideal for creating custom displays and fixtures that can be easily modified or rearranged. Additionally, aluminum profiles offer a sleek and modern aesthetic that can enhance the overall look and feel of a retail space.

- Q: What are the major factors determining the quality of aluminum profiles?

- Material, section size, fit tolerance, surface treatment quality, etc.

- Q: What are the different cutting methods for aluminum profiles?

- Depending on the specific requirements and desired outcome, there are various cutting methods available for aluminum profiles. Some of the most commonly used cutting methods for aluminum profiles are as follows: 1. Saw cutting: By using a saw blade, the aluminum profile can be cut. This method is versatile and widely employed, offering high precision and producing straight cuts. Saw cutting is suitable for both small and large-scale production. 2. Shearing: This method involves the use of a guillotine-like tool to cut through the aluminum profile. Shearing is a quick and efficient method for cutting straight lines in aluminum profiles of different thicknesses. However, it may not be suitable for cutting complex shapes or angles. 3. CNC machining: Computer numerical control (CNC) machining is a highly precise cutting method that utilizes computer-controlled machines to cut aluminum profiles. It provides a wide range of cutting options, including complex shapes, angles, and contours. CNC machining is ideal for custom or intricate designs, but it may be more time-consuming and costly compared to other methods. 4. Laser cutting: Laser cutting utilizes a high-powered laser beam to cut through the aluminum profile. It is a precise and efficient method that can produce intricate and detailed cuts with minimal heat distortion. Laser cutting is highly suitable for thin aluminum profiles and is commonly used in industries such as aerospace and automotive. 5. Waterjet cutting: Waterjet cutting involves the use of a high-pressure stream of water mixed with an abrasive material to cut through the aluminum profile. It is a versatile method that can cut through various thicknesses and materials, including aluminum. Waterjet cutting is ideal for cutting complex shapes and has minimal heat-affected zones. 6. Plasma cutting: Plasma cutting utilizes a plasma torch to cut through the aluminum profile. It is a fast and efficient method that can handle thicker aluminum profiles. However, the heat generated during plasma cutting can cause distortion and may require additional post-cutting processes. In conclusion, the selection of a cutting method for aluminum profiles depends on factors such as desired cut quality, complexity of the design, production volume, and budget. Considering these factors is essential in choosing the most suitable cutting method for a specific application.

- Q: Can aluminum profiles be recycled indefinitely?

- Aluminum profiles possess the remarkable ability to be recycled endlessly. Unlike other materials, aluminum remains intact throughout the recycling procedure, allowing it to be melted and molded into fresh profiles without forfeiting its inherent qualities. Consequently, aluminum profiles enjoy an eternal life cycle. Opting for aluminum recycling proves to be an environmentally sustainable choice as it demands considerably fewer resources and energy than the production of new aluminum. Furthermore, the recycling process can be performed indefinitely without compromising the quality, rendering aluminum among the most frequently recycled substances globally.

- Q: Are there any special considerations for installing aluminum profiles?

- Yes, there are a few special considerations for installing aluminum profiles. Firstly, it is important to ensure that the installation surface is clean and free from any debris or contaminants that could affect the adhesion or stability of the profiles. Secondly, proper measurement and alignment are crucial for a precise and secure installation. Additionally, it is advisable to use appropriate tools and techniques for cutting and shaping the profiles to avoid any damage or distortion. Finally, if the installation involves outdoor or high-moisture areas, it is recommended to use aluminum profiles that are specifically designed for such conditions to ensure longevity and durability.

- Q: What are the features of the poor aluminum profiles?

- Low precision, bad feel, and so on, some inferior shape.You'd better go to the manufacturer you trust.

- Q: Can aluminum profiles be custom-designed or customized?

- Yes, aluminum profiles can be custom-designed or customized according to specific requirements. Aluminum is a highly versatile material that can be easily shaped and manipulated into different forms. Customizing aluminum profiles allows for the creation of unique shapes, sizes, and finishes to meet the specific needs of various applications. Custom design and customization of aluminum profiles can involve altering dimensions, creating intricate shapes, adding slots or holes for assembly, incorporating specific features or accessories, and even applying various surface treatments or coatings. This flexibility in design and customization enables aluminum profiles to be used in a wide range of industries and applications, such as construction, automotive, aerospace, electronics, and more. The process of customizing aluminum profiles typically involves collaboration between the manufacturer and the customer. The manufacturer will work closely with the customer to understand their requirements, provide technical support, and offer design solutions that meet their specific needs. This may include creating prototypes, conducting tests, and making adjustments until the desired custom design is achieved. Overall, aluminum profiles can indeed be custom-designed or customized to suit specific requirements, making them a preferred choice for many industries seeking unique and tailored solutions.

- Q: Can aluminum profiles be used for soundproofing?

- Aluminum profiles have the ability to offer some soundproofing benefits, although they may not provide the same level of sound reduction as specialized soundproofing materials like acoustic panels or insulation. These profiles are commonly used in the construction industry for various purposes, such as window frames and door frames. When incorporated into soundproofing applications, aluminum profiles can effectively minimize noise transmission through windows and doors. The lightweight and durable nature of aluminum makes it an ideal material for blocking or dampening sound waves. Its structural integrity allows for the creation of tight seals, resulting in reduced sound leakage and improved sound insulation. To further enhance soundproofing, aluminum profiles can be combined with other materials like rubber gaskets or weatherstripping. This combination enhances the sealing properties and contributes to better sound insulation. Additionally, the use of double or triple glazing with laminated glass in conjunction with aluminum profiles can provide even better sound insulation. However, it is important to consider that the effectiveness of aluminum profiles in soundproofing depends on various factors. These factors include the thickness and quality of the profiles, the design of the window or door system, and the overall construction of the building. In conclusion, while aluminum profiles can assist in reducing noise transmission through windows and doors, they should be viewed as part of a comprehensive soundproofing strategy rather than the sole solution.

Send your message to us

Structural Aluminum Profiles for Industrial Material

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords