Sapa Aluminum Profiles for Door and Window Making

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile for Door and Windows Making Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Door and Windows Making:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

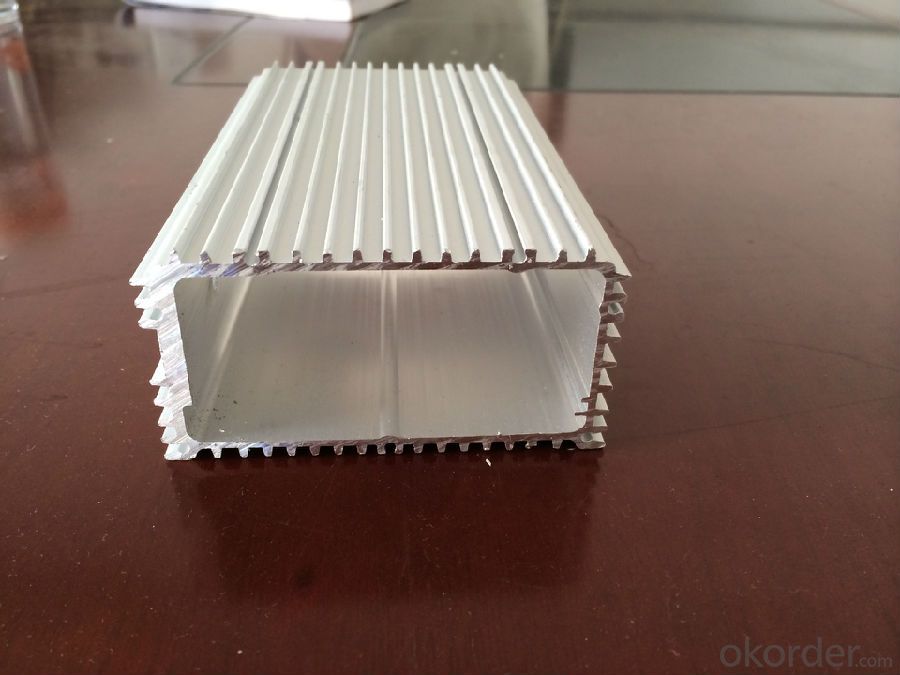

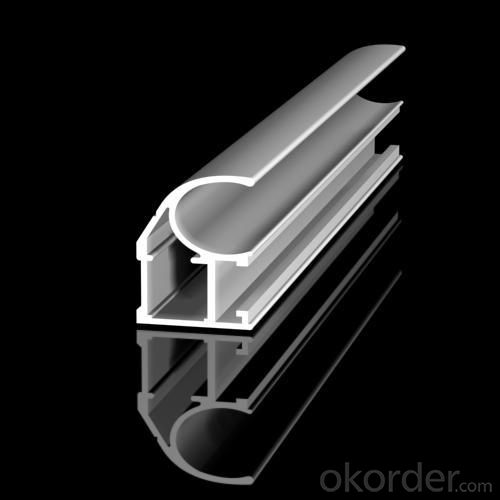

3.Aluminium Profile for Door and Windows Making Images:

4.Aluminium Profile for Door and Windows Making Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks about the various types of aluminum profiles that are specifically used for flooring applications.

- <p>Aluminum profiles for flooring are designed to provide structural support and stability to the flooring system. Common types include: 1. T-profiles, which are used as support beams and can be easily connected to create a grid structure. 2. U-profiles, often used as edge trims or for creating a border around the flooring area. 3. H-profiles, which are suitable for heavy-duty applications and provide high load-bearing capabilities. 4. L-profiles, used for creating corners or edges in flooring systems. 5. C-profiles, which are used for covering or hiding the edges of the floor. Each type offers different benefits and is chosen based on the specific requirements of the flooring project, such as load capacity, aesthetic considerations, and ease of installation.</p>

- Q: How to prevent the aging of aluminum profile hardness is not enough?

- Raw materials, alloy, cast bar qualityDuring extrusion, the outlet temperature is guaranteed to be above the solid solution temperature,Cooling, quenching speed guaranteed as fast as possibleWhen the time limit is guaranteed, the process is executed without overheating and time is guaranteed.

- Q: The user is asking for methods to prevent aluminum profiles from warping or twisting while being installed.

- <p>To avoid warping or twisting of aluminum profiles during installation, ensure proper handling and support. Use sturdy brackets and supports to maintain alignment and prevent bending. Keep the profiles clean and free of debris that could cause uneven pressure. Avoid overtightening fasteners, which can cause stress and deformation. Use the correct tools and techniques for cutting and drilling to avoid damage. Maintain a consistent temperature and humidity during the installation process, as extreme conditions can affect the material's stability. Finally, inspect the profiles regularly for any signs of warping or twisting and address issues promptly.</p>

- Q: What specific coatings or finishes are necessary for aluminum profiles to withstand cold weather conditions?

- <p>In cold climates, aluminum profiles may require special coatings or finishes to enhance durability and resistance to corrosion. These can include anodizing, which forms a protective oxide layer on the aluminum surface, or powder coating, which provides a hard, durable finish. Additionally, thermal breaks may be incorporated into the design to reduce heat transfer and prevent condensation. It's crucial to select the right finish based on the specific environmental conditions and the intended use of the aluminum profile.</p>

- Q: What's the price of aluminum alloy die castings and aluminum profiles?

- Aluminum alloy extrusion is a method of extruding cold drawn and extruded aluminum alloy through extrusion die. Aluminum alloy die casting is hot processing, melting aluminum alloy into the mold cooling molding, can be taken out from the mold, can be processed very complex products. What do you mean by "expensive"?

- Q: What are the methods to prevent water infiltration in the gaps between aluminum profiles during the installation process?

- <p>To prevent water from getting into gaps between aluminum profiles during installation, use high-quality sealants and gaskets. Ensure proper alignment and fit of the profiles to minimize gaps. Install weep holes to allow water to drain out. Apply a water-resistant membrane or flashing behind the profiles. Regularly inspect and maintain the installation to identify and fix any issues promptly. Proper installation techniques and materials selection are crucial to prevent water infiltration.</p>

- Q: Can aluminum profiles be used for outdoor applications?

- Yes, aluminum profiles can be used for outdoor applications. Aluminum is a highly versatile and durable material that is resistant to corrosion, making it suitable for use in outdoor environments. It has excellent weather resistance and can withstand exposure to sunlight, rain, and temperature variations without deteriorating. Aluminum profiles are commonly used in outdoor applications such as construction, architecture, transportation, and outdoor furniture. They offer strength, stability, and longevity, making them a popular choice for outdoor projects. Additionally, aluminum profiles can be finished with protective coatings or anodized to further enhance their resistance to outdoor elements.

- Q: Can aluminum profiles be used for solar power systems?

- Yes, aluminum profiles can be used for solar power systems. Aluminum is a widely used material in the construction of solar panels and their support structures. It is preferred for its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum profiles are often used for the framing and mounting of solar panels, as they provide structural stability and durability. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for solar power systems.

- Q: What are the different assembly options available for aluminum profiles?

- There are several assembly options available for aluminum profiles, including mechanical fastening methods such as screws, bolts, and rivets. Additionally, adhesive bonding and welding techniques can also be used to join aluminum profiles together. The choice of assembly method depends on factors such as the desired strength, aesthetics, and ease of disassembly if required.

- Q: Can aluminum profiles be used for conveyor belts?

- Indeed, conveyor belts can indeed utilize aluminum profiles. Aluminum, a material known for its versatility and lightness, finds widespread use in various industrial settings, including conveyor systems. The utilization of aluminum profiles for conveyor belts provides numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and effortless customization. These profiles can be easily manipulated into diverse shapes and sizes to cater to the specific requirements of the conveyor system. Moreover, opting for aluminum profiles proves to be an economical decision as they necessitate minimal maintenance and boast a longer lifespan compared to alternative materials. Consequently, the durability, versatility, and cost-effectiveness of aluminum profiles render them a suitable choice for conveyor belts.

Send your message to us

Sapa Aluminum Profiles for Door and Window Making

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords