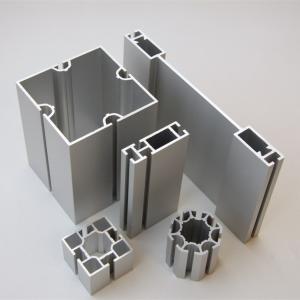

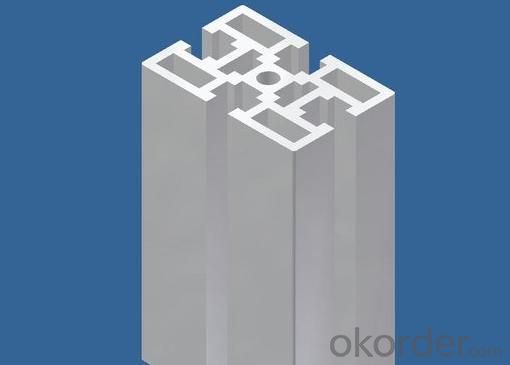

2020 T-Slot Aluminum Profiles Extrusion 6063-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles 6063-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

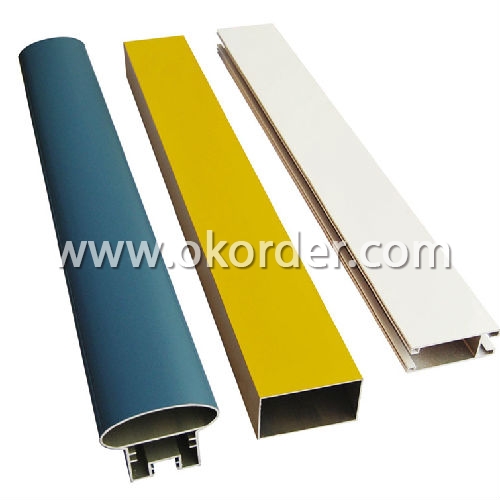

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6063-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

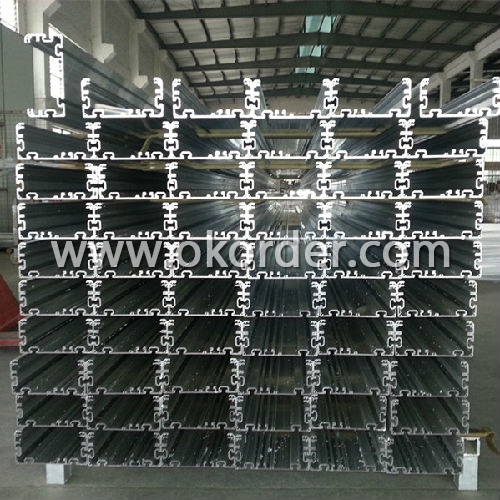

3 Packaging & Delivery of Aluminum Profiles 6063-T5

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles 6063-T5

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: What is the material content of 4040 aluminum alloy profiles?

- Aluminium alloy grade: 6063Silicon (Si) 0.2-0.6%,Iron (Fe) 0.35%,Copper (Cu) 0.1%,Manganese (Mn) 0.1%,Magnesium (Mg) 0.45-0.9%,Chromium (Cr) 0.1%,Zinc (Zn) 0.1%,Titanium (Ti) 0.1%Other metals accounted for 0.15% of the total,Aluminum (Al) 97.35--98.35%Shanghai Australia Hong Industrial Aluminum Co., Ltd. specializes in providing1. mold development and design2. extrusion of industrial aluminum extrusions3. industrial aluminum parts4. industrial aluminum profiles and assembly lines, tables, transmission line equipment development and installation

- Q: Are aluminum profiles suitable for indoor applications with high humidity?

- Yes, aluminum profiles are suitable for indoor applications with high humidity. Aluminum is highly resistant to corrosion and does not rust, making it an ideal material for humid environments. Additionally, aluminum profiles can withstand moisture and humidity without warping or deteriorating, ensuring their durability and suitability for such conditions.

- Q: Do aluminum profiles require regular maintenance?

- Maintenance is necessary for aluminum profiles. However, the frequency and extent of maintenance depends on how they are used and the environment they are in. Although aluminum profiles are known for being durable and resistant to corrosion, they can still become dirty, grimy, and oxidized over time. To keep them clean and looking good, it is recommended to regularly clean them with mild soap or detergent and water. It is also a good idea to lubricate any moving parts, like hinges or sliding mechanisms, to ensure they operate smoothly. Additionally, it is important to inspect the profiles for any signs of damage, such as cracks or loose connections, so that any issues can be addressed before they get worse. By doing regular maintenance, the lifespan of aluminum profiles can be extended and their performance can be optimized.

- Q: This question asks about the various types of fastening mechanisms used to attach exterior walls to the structural frames of buildings.

- <p>Different types of fasteners used to secure exterior walls to building frames include nails, screws, bolts, and anchors. Nails are commonly used for wood-framed structures, while screws offer greater holding power. Bolts are used in steel or concrete structures and can be either through-bolts or expansion bolts. Anchors, such as masonry or concrete anchors, are used for securing to masonry or concrete walls. Additionally, adhesives and mechanical fasteners like clips and brackets are also used depending on the material and design of the exterior wall and building frame.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: Can aluminum profiles be painted or coated?

- Yes, aluminum profiles can be painted or coated. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance, provide protection against corrosion, or improve its durability. There are various methods of painting or coating aluminum profiles, including powder coating, anodizing, and liquid coating. Powder coating is a popular choice as it offers a durable and uniform finish, while anodizing provides a protective oxide layer on the surface of the aluminum. Liquid coating, on the other hand, allows for a wide range of colors and finishes. Overall, whether you want to change the color, improve the aesthetics, or protect the aluminum profiles, painting or coating is an effective and feasible option.

- Q: Is it possible to utilize recycled aluminum extrusions in a construction project to lessen the environmental footprint?

- <p>Yes, using recycled aluminum extrusions in your building project can significantly reduce environmental impact. Recycled aluminum requires less energy to produce compared to new aluminum, reducing greenhouse gas emissions. It also conserves natural resources by decreasing the need for mining. Additionally, incorporating recycled materials can contribute to a project's sustainability goals and potentially qualify for green building certifications, enhancing the building's marketability and appeal.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of buildings.

- <p>Aluminum profiles in building construction offer several advantages such as high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures, and they are recyclable, contributing to sustainability. Additionally, aluminum profiles can be easily shaped and joined, making them versatile for various architectural designs. However, they also have disadvantages. Aluminum is a good conductor of heat, which can lead to thermal bridging and energy inefficiency if not properly insulated. It can also be more expensive than some traditional materials like steel or wood. Moreover, aluminum's light color can cause glare issues, and it may require additional protective coatings to prevent weathering and maintain its appearance over time.</p>

- Q: How to use aluminum profile on the side of roller conveyor?

- 1, aluminum has four T groove, convex roller bearing seat or shaft seat made matched with the vertical direction, and then through the bolt and nut groove can be fixed bearing or shaft seat, the roller spacing can be adjusted.2, with Thomas, first according to Thomas roller is fixed on the inner side section spacing, then the roller milling flat shaft directly to the groove in the thomas.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

2020 T-Slot Aluminum Profiles Extrusion 6063-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords